The information and technical data disclosed in this

document may be used and disseminated only for

the purposes and to the extent specifically

authorized in General Monitors in writing. Such

information and technical data are proprietary to

General Monitors and may not be used or

disseminated except as provided in the foregoing

sentence.

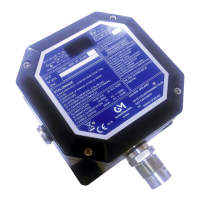

Instruction Manual 01/18

General Monitors reserves the right to change published

specifications and designs without prior notice.

Part No. MANS4100C-EU

Revision Q/01-18