MTD Engine - Series 350/450/650

26

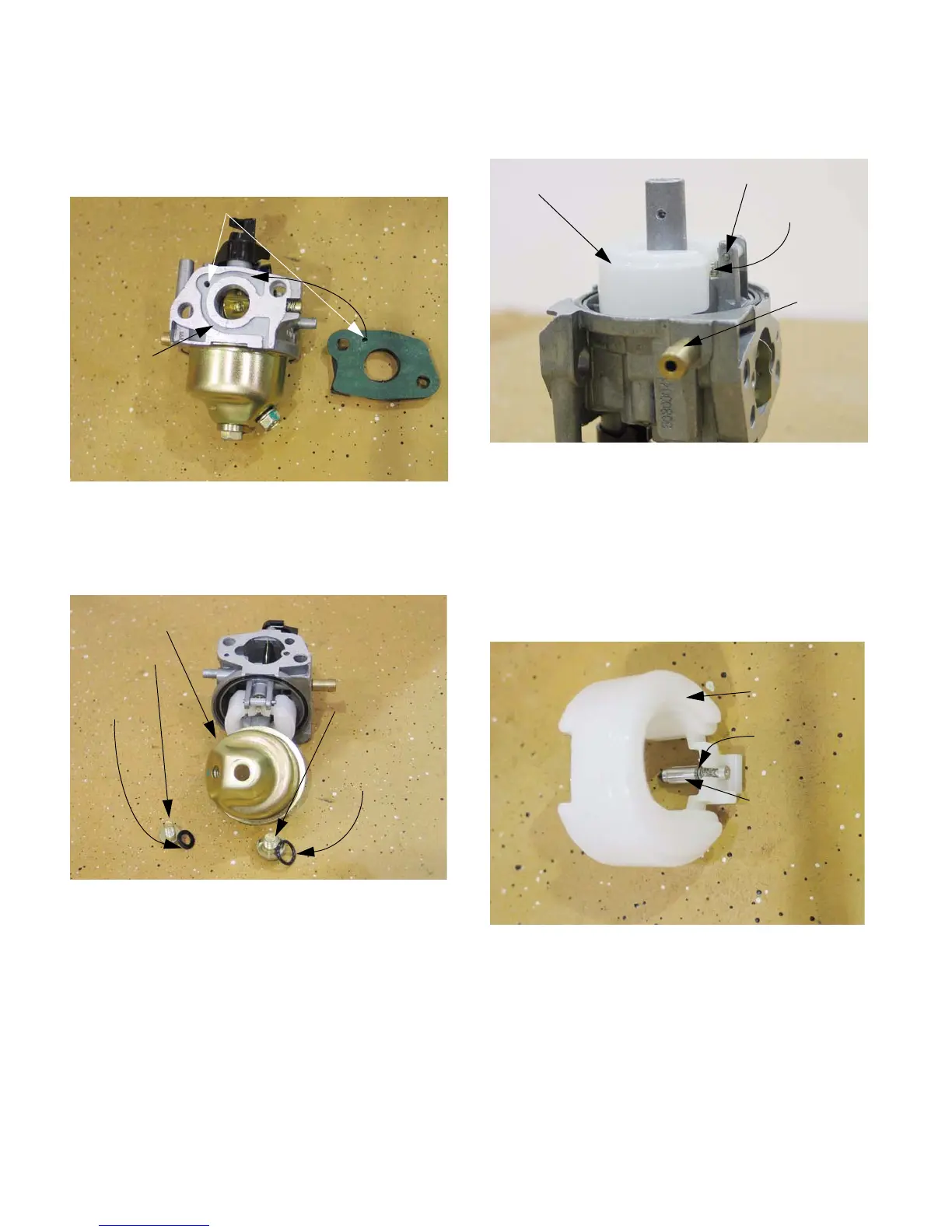

8.22. There is a corresponding passage recessed into

the mating surface where the throttle end of the

carburetor housing meets the gasket.

See Figure 8.22.

8.23. Bowl removal is a logical place to begin carbure-

tor disassembly. Remove the bowl bolt using a

10mm wrench. See Figure 8.23.

8.24. From this point an assessment can be made

about the viability of rebuilding the carburetor.

• If extensive corrosion is evident, replace the car-

buretor.

• If varnish build-up is too extensive to clean,

replace the carburetor.

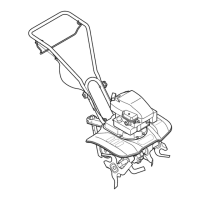

8.25. When inverted, the float should rest in a level

position. See Figure 8.25.

8.26. Remove the pin that the float hinges on to

remove the float.

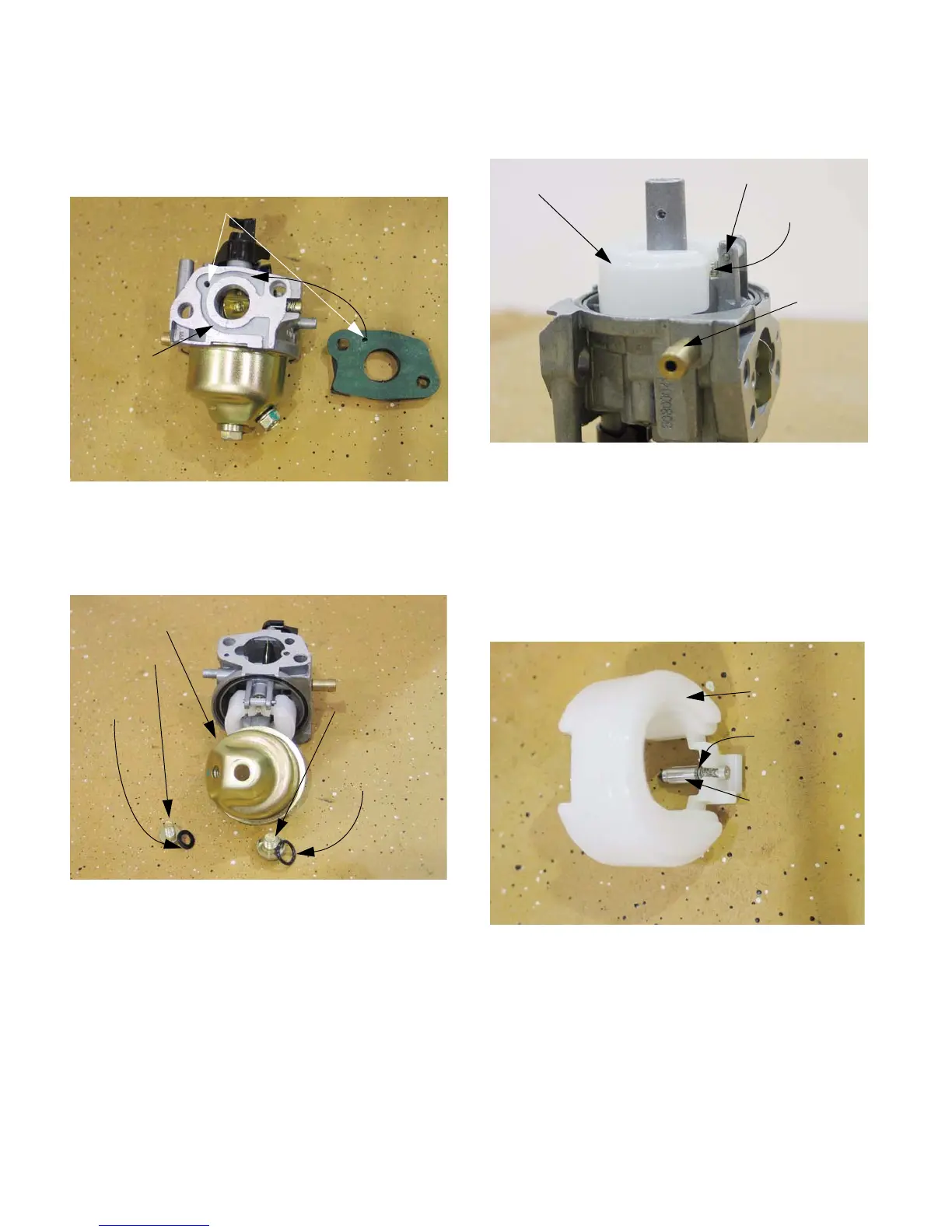

8.27. The float is not adjustable. Spring tension

against the float valve begins to build from the

horizontal position, putting progressively more

pressure between the tip of the valve and the

seat. See Figure 8.27.

8.28. Because the float valve is crucial to the function-

ing of the carburetor, and the viton tip of the

valve is subject to wear, it is suggested that tech-

nicians replace the valve and spring any time the

carburetor is disassembled for cleaning.

Figure 8.22

Bowl vent port

Bowl vent

channel

Figure 8.23

Float bowl

Drain bolt

Flat fiber

gasket

Bowl bolt

with recess in

head for O-ring

Gasket seal

Figure 8.25

Float

Float pin

Float valve

Fuel inlet

Figure 8.27

Float

Compression

spring

Float valve

www.mymowerparts.com

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

Loading...

Loading...