318 Load Unit

74

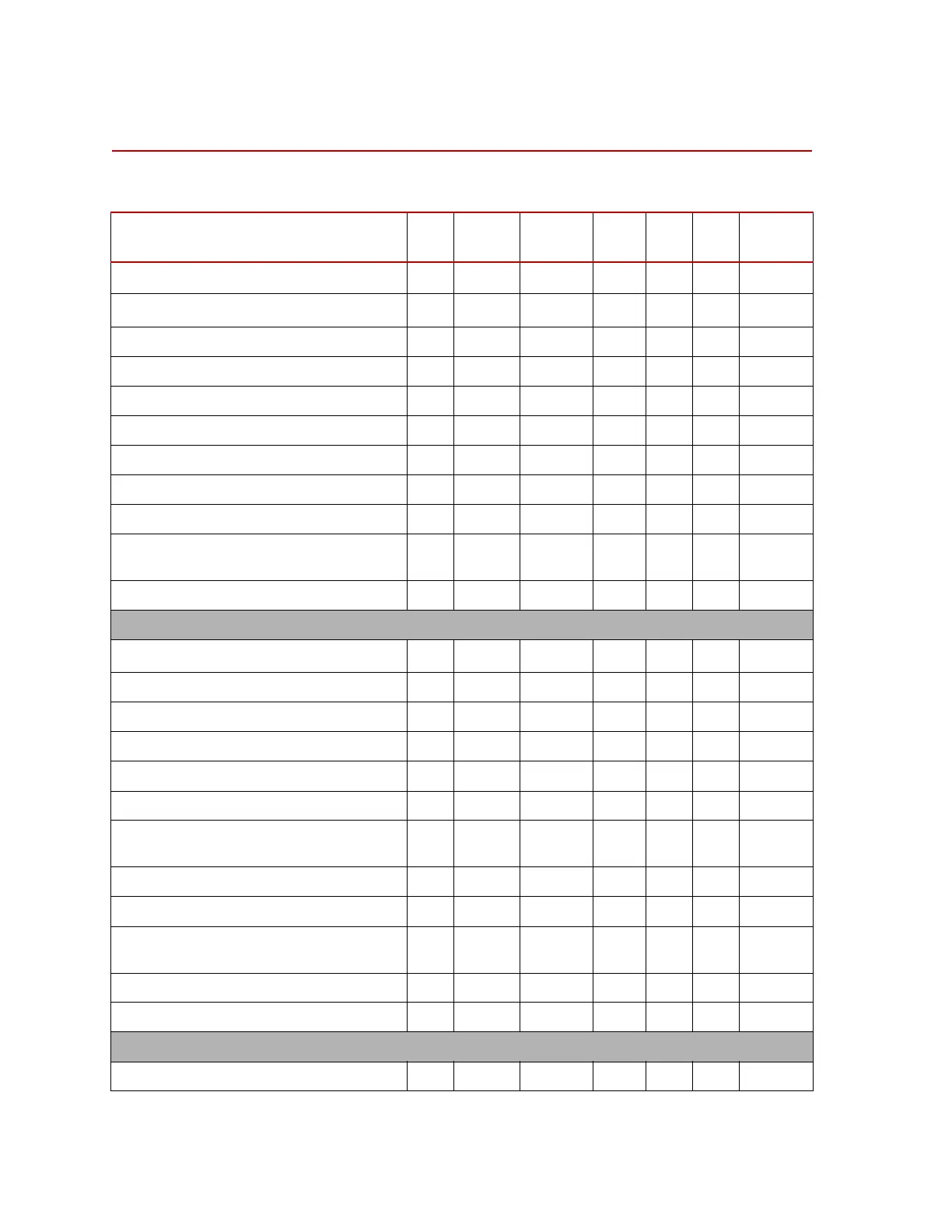

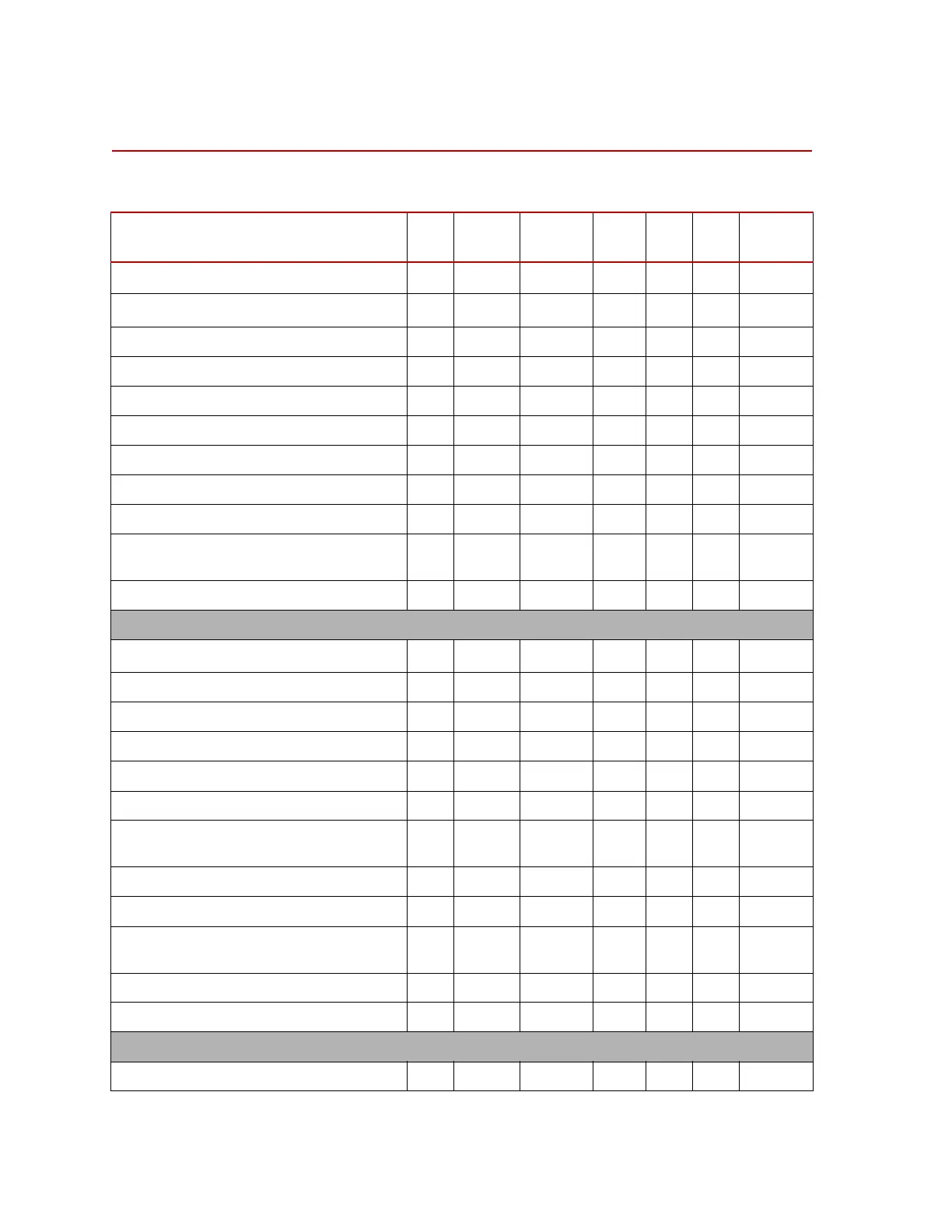

Routine Maintenance Overview Checklist

Maintenance

Routine Maintenance Overview Checklist

Recommended service to be performed at each running time interval noted

C

ALENDAR TIME USING 8 HOUR RUNNING TIME RATE

PER DAY

DAILY WEEKLY BIWEEKLY ANNUALLY

RUNNING TIME-HOURS 8 40 80 500 1000 1,500 2,000

Check Actuator Platen Area to be Clean

X

*

Monitor Filter Indicators X

Check Hoses/Cables/Connectors X

Check Crosshead/Lifts/Supports X

Check Actuator to be Dry X

Check Hydraulic Service Manifold X

Check Lift Seal Condition to be Dry X

Check Lock Seal Condition to be Dry X

Bionix Lubricate Axial/Torsional Spline

(75-100 hrs)

X

Check Actuator X

Crosshead/Load Frame

Check Crosshead/Lifts/Supports

MTS

†

MTS MTS MTS MTS

Lift Seal Condition is Dry MTS MTS MTS MTS MTS

Lock Seal Condition is Dry MTS MTS MTS MTS MTS

Crosshead Columns are Clean MTS MTS MTS MTS MTS

Column Abrasions are Acceptable MTS MTS MTS MTS MTS

Crosshead Speed is Appropriate MTS MTS MTS MTS MTS

Crosshead Unlock Causes Program

Interlock

MTS MTS MTS MTS MTS

Load frame Support Airbags/Pads MTS MTS MTS MTS MTS

Crosshead Movement is Smooth MTS MTS MTS MTS MTS

Hydraulic Crosshead Locks are

Functioning Properly

MTS MTS

Bleed Crosshead Lift Cylinders MTS MTS

Lubricate Manual Crosshead Lock Bolts MTS

Actuator

Cursory Check of Actuator MTS MTS MTS MTS

Loading...

Loading...