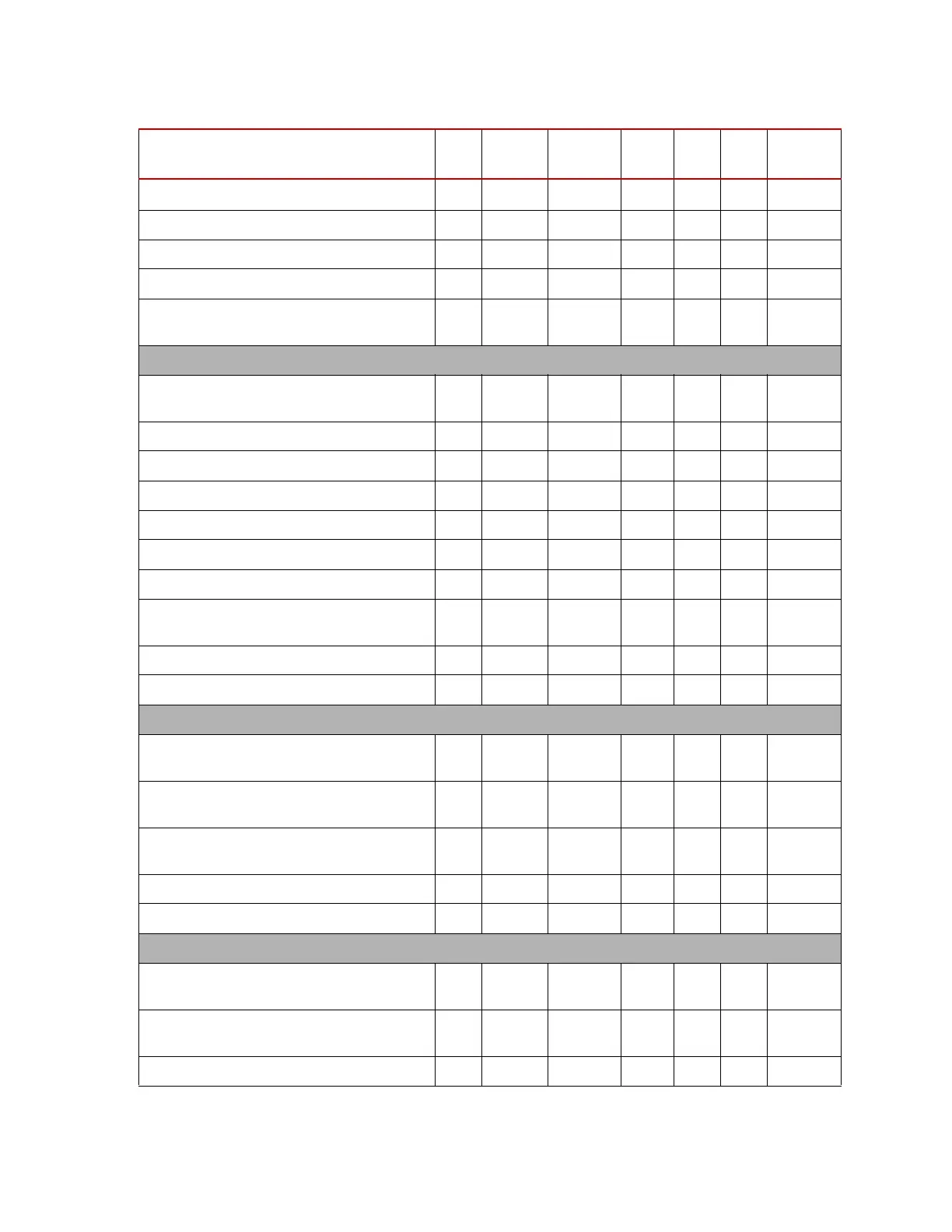

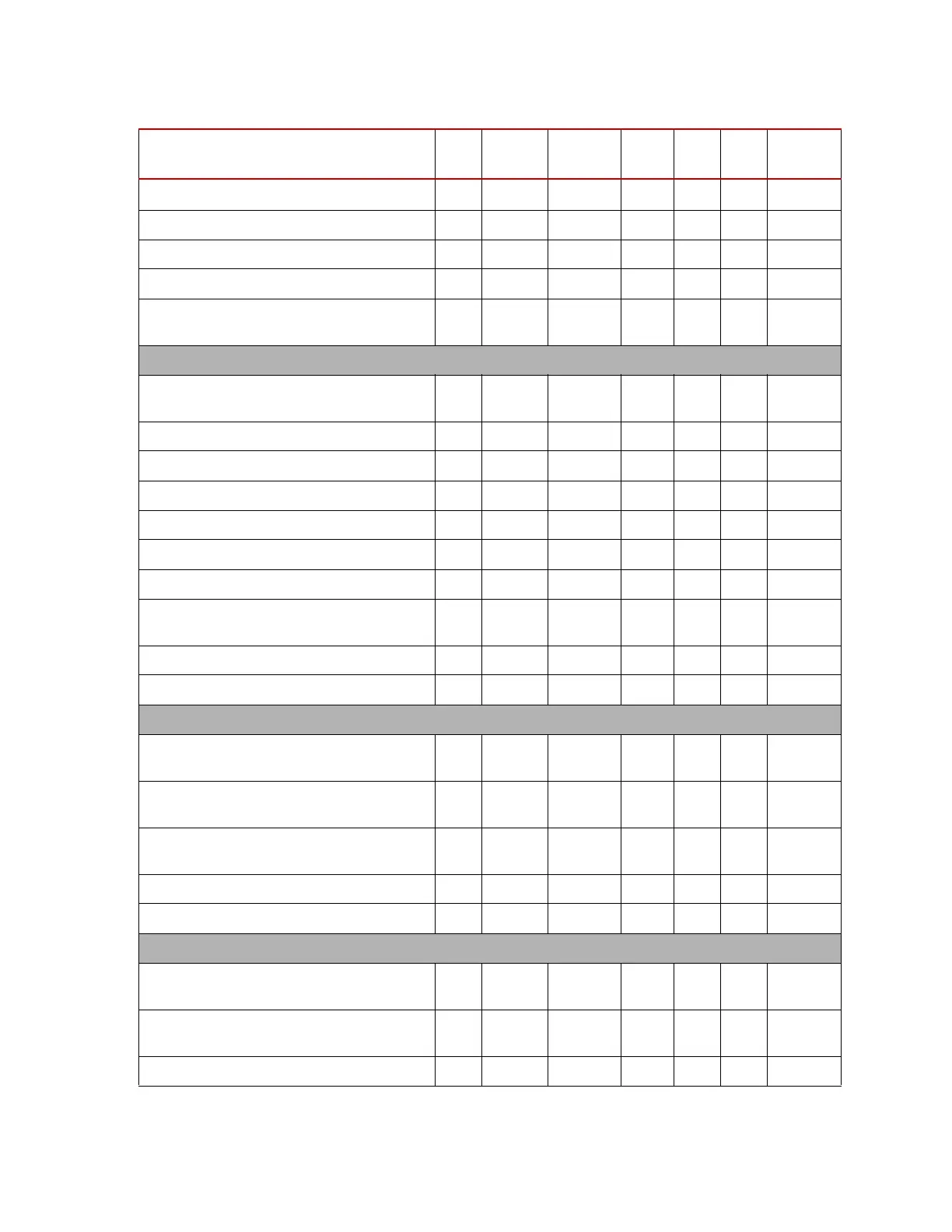

Routine Maintenance Overview Checklist

318 Load Unit Maintenance

75

Actuator Area is Dry MTS MTS MTS MTS

Actuator Platen Area is Clean MTS MTS MTS MTS

Piston Rod Wear is Acceptable MTS MTS MTS MTS

Bionix Lubricate Axial/Torsional Spline

(75-100 hrs)

MTS MTS MTS MTS

Hydraulic Service Manifold

Cursory Check of Hydraulic Service

Manifold

MTS MTS MTS MTS

Monitor Filter Indicators MTS MTS MTS MTS

Manifold Hose Connections are Tight MTS MTS MTS MTS

Accumulator Connections are Dry MTS MTS MTS MTS

Accumulator Connections are Tight MTS MTS MTS MTS

Accumulator Caps/Guards are Present MTS MTS MTS MTS

Oil on the Gas Side of the Piston MTS MTS MTS MTS

Check and Adjust Pressure in

Accumulator

MTS MTS MTS MTS

Change Filters MTS

Low Pressure Adjustment (Model 294) MTS

Hoses/Cables

Cursory Check of Hoses/Cables/

Connectors

MTS MTS MTS MTS

Absence of Hose Abrasions, Blisters,

Vulcanizing

MTS MTS MTS MTS

Cable Condition and Routing is

Acceptable

MTS MTS MTS MTS

Check Transducer Connections MTS MTS MTS MTS

Hose Connections and Crimps are Dry MTS MTS MTS MTS

Complete System

Overall System Condition is Acceptable to

Use

MTS MTS MTS MTS

Turning Parameters are Appropriate/

System Stable

MTS MTS MTS MTS

E-Stop is Working if Applicable MTS MTS MTS MTS

Recommended service to be performed at each running time interval noted

C

ALENDAR TIME USING 8 HOUR RUNNING TIME RATE

PER DAY

DAILY WEEKLY BIWEEKLY ANNUALLY

RUNNING TIME-HOURS 8 40 80 500 1000 1,500 2,000

Loading...

Loading...