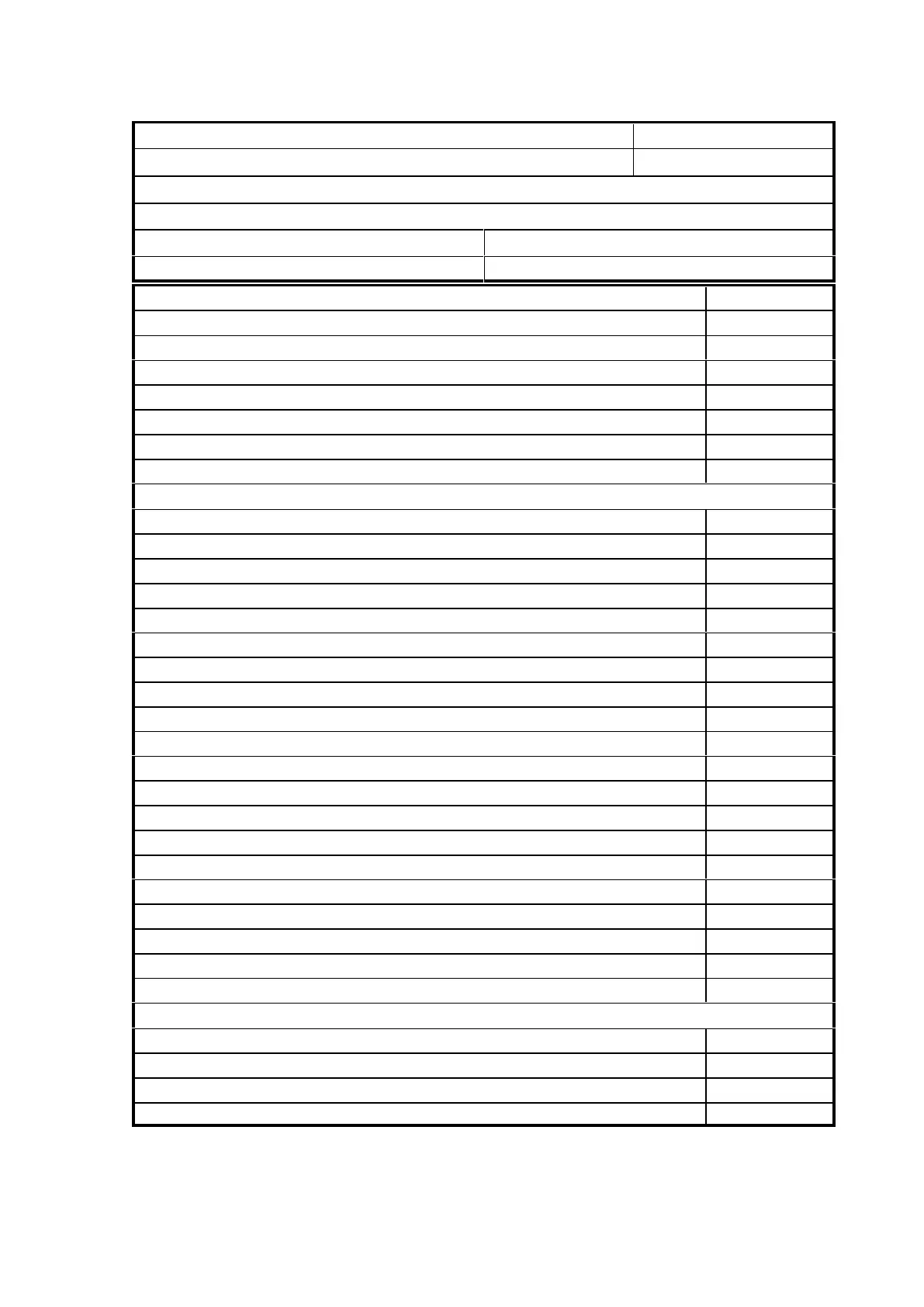

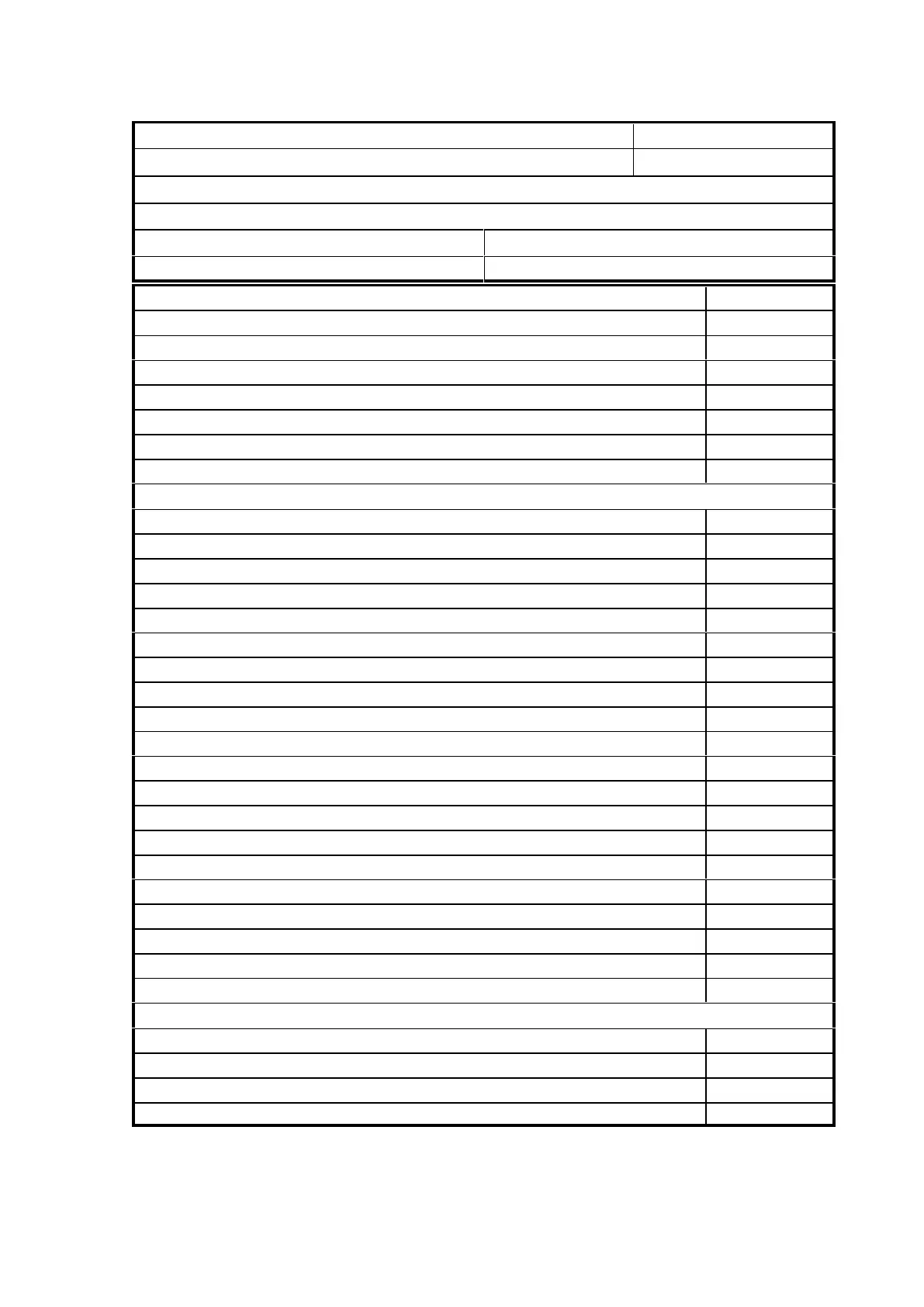

Machine Training Schedule

Company :

Date:

Contact :

Serial No:

Technician :

The following persons have been trained in the procedures shown below:

Trainee: Trainee:

Trainee: Trainee:

Description Yes/No

Basic operation procedures in GUI software including:

Adding Tools and Tool Descriptions

Mapping Tools to ATC

Other:

Other:

Other:

Other:

Basic operation procedures on the Multicam machine:

Machine On/Off procedure

Using Sub Console

Selecting Folders and Files

Starting a Job (Start Button)

Pausing a Job (Stop Button)

Seeking a shape within a job

FUNC 9 Aborting a job

FUNC 12 Machine Homing

FUNC 25 Individual Tool Tip

FUNC 26 Multiple Tool Tip

FUNC 31 Pick Up a Tool

FUNC 34 Put Tool Away

FUNC 50 Turning Appliances ON/OFF

FUNC 50.1 Setting Appliances AUTO/OFF

Vacuum Table operation on material without bows

Use of Clamps for bowed material

Correct Lubrication procedure for Oscillating Knifes

Safe use of automatic, semi-automatic or manual clamping devices

Use of PPE to prevent injury through cuts by cutting tools and blades

Other

Basic maintenance procedures on the Multicam machine:

Draining Micro Filter

Cleaning Air filter (if a vacuum table)

Dust Extraction bag emptying

General cleaning procedure

Technician Signature___________________Customer Signature____________________

Loading...

Loading...