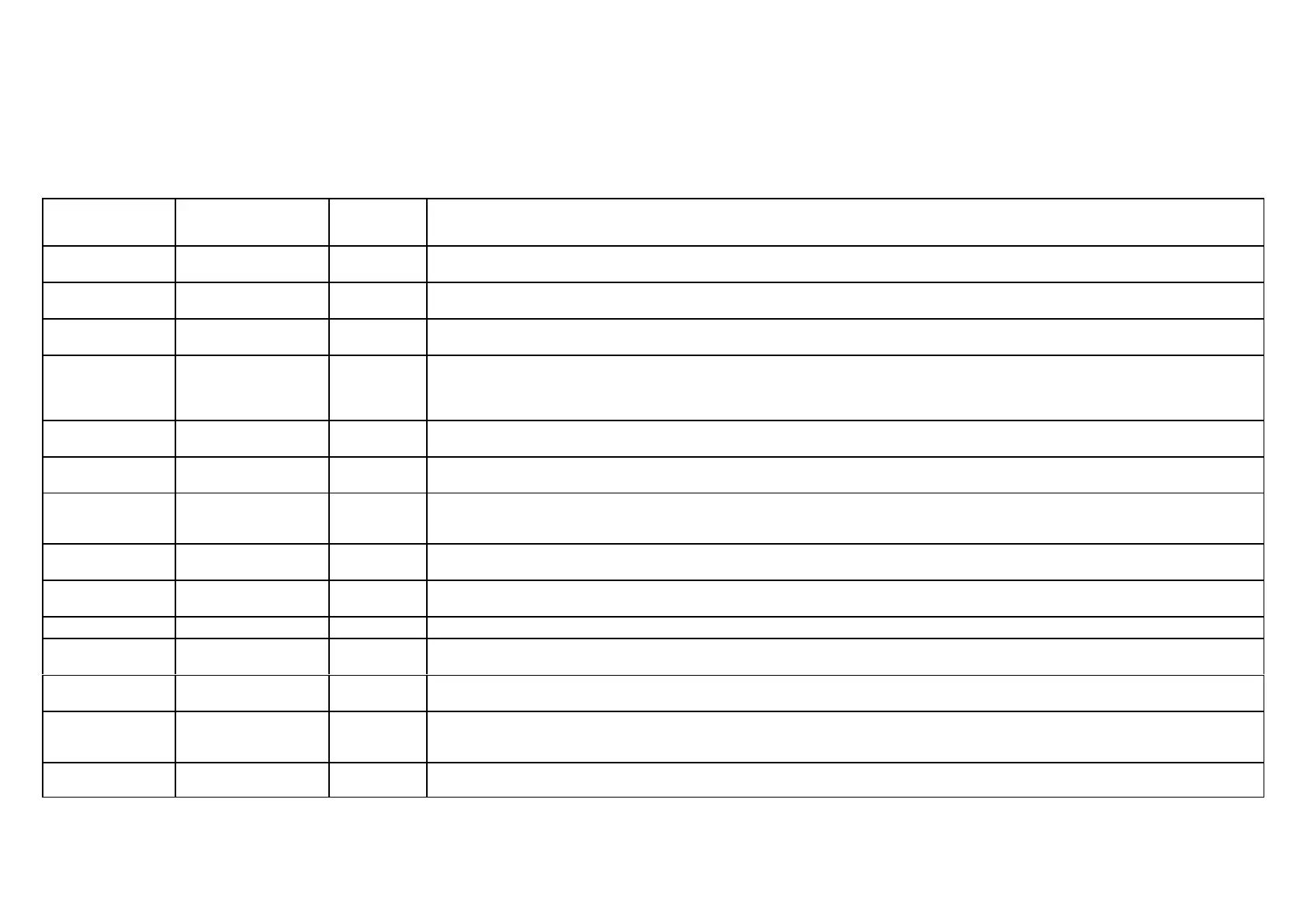

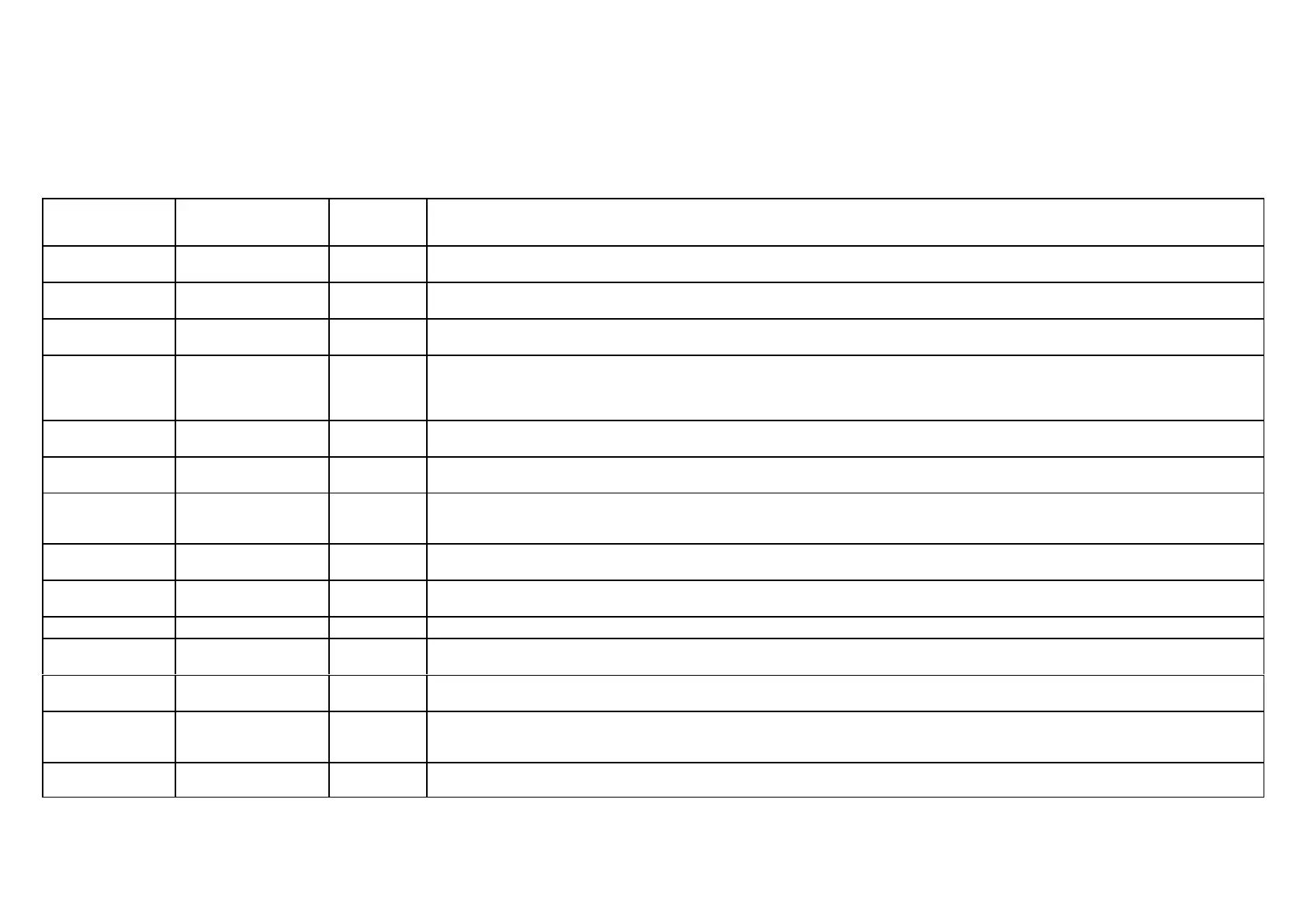

Machine Safety Hazard Identification, Assessment and Control

Note: Machine commissioning and training is not complete until this document has been signed and presented to the machine operator or chief safety officer. This document to be

used in conjunction with your in-house Safe Work Method Statement (SWMS) and displayed at the machine in plain site of the machine operator.

Machine Description: Multicam CNC Flat Bed Routing Machine Model: __________ Serial No: _____________

Item/Device Hazard Identification

Hazard

Assessment

Risk Control Strategies (recommended for Purchaser/Buyer/User)

GANTRY STRIKING/CRUSHING LOW

Maintain safe working distance from machine when in operation. Do not lean on machine when in operation. Do not place loose objects in the path of the gantry. Do

not lean objects against machine. Remove all loose objects around moving parts. Keep well clear of moving parts.

CLAMPING

SYSTEMS

STRIKING/CRUSHING MEDIUM Ensure that all clamping systems are free of obstructions and that no other personnel are likely to be injured or engaged prior to activating the clamps.

VACUUM BED STRIKING LOW

In the event of vacuum pump failure during cutting, cut parts may move or be ejected from the machine bed. Maintain a safe distance from the machine when in

operation. Wear suitable PPE. Do not operate machine if machine table vacuum is low or vacuum pump/s are faulty.

SPINDLE

KNIFE HEADS

CUTTING

ENTANGLEMENT

STRIKING

MEDIUM

Isolate main power before changing/inspecting cutters or knife blades. Ensure tool is not rotating or moving before changing/inspecting cutters or knife blades.

Hands must always be kept well clear from spindle and cutters when machine is in operation. Long or loose hair must be covered. Loose clothing/jewellery must not

be worn when operating the machine or changing/inspecting cutters. All materials must be suitably clamped/held/secured before cutting. Use of suitable PPE (cut

resistant gloves) is recommended when handling router cutters or knife blades.

AIR ASSIST DEVICE

CUTTING/CRUSHING

SHEARING

MEDIUM

Air assist is used to control the weight of the spindle. A sudden release in air pressure or disruption of controlling circuitry will cause the spindle to drop rapidly.

Even if power is off or air supply is not present. Keep hands and fingers clear or all moving parts and crush points.

CONTROLLER AND

POWER BOX

ELECTRICAL MEDIUM

All electrical enclosures should only be opened with the correct tool that is not to be kept with the machine. Electrical work should only be carried out a licensed

electrician.

AUTOMATIC TOOL

CHANGER

ENTANGLEMENT

STRIKING

ELECTRICAL

LOW

Ensure all covers are secured before starting machine. Do not operate machine with tool change cabinet open. All electrical enclosures should only be opened with

the correct tool that is not to be kept with the machine. Electrical work should only be carried out a licensed electrician.

MIST SPRAYER CONTAMINATION LOW

Use only approved products in the Mist Sprayer Unit. Do not use flammable products such as methylated spirit in the Mist Sprayer Unit. Area must be well ventilated

to prevent build up of mist vapour.

DUST COLLECTOR

CONTAMINATION/NOISE

FATIGUE

MEDIUM

A dust extraction system must be used if cutting porous materials or materials that create dust or fibres during the cutting process. Hearing and eye protection must

be worn when operating the machine.

MACHINE BED ERGONOMIC MEDIUM Heavy or large pieces must me carried/loaded by more than one person or loaded using mechanical or automated methods.

MATERIAL LOADER

STRIKING/CRUSHING/

SHEARING

LOW Do not stand behind the gantry when executing automated material loading. Do not place hands or fingers between the machine bed/frame and the on-loading table

MATERIAL

OFFLOADING DEVICE

STRIKING/CRUSHING LOW

Do not stand in front of the gantry when executing automated material offloading. Do not place hands or fingers between the machine unloading arm and the

product being removed from the machine.

OFFLOADING TABLE

OR CONVEYOR

STRIKING/CRUSHING LOW

The machine unloading arm moves the finished product on to the offloading table or conveyor. Ensure that the offloading table or conveyor bed height is below the

machine bed height. Ensure that the offloading table or conveyor bed is placed within 10mm of the machine bed. Do not place hands or fingers between the product

being removed from the machine and the offloading table or conveyor

OTHER HAZARDS NOISE, FATIGUE LOW

Appropriate PPE must be worn when operating the machine. In enclosed areas or small premises noise from the dust extraction system, vacuum pumps and

spindle can elevate ambient noise levels. This must be taken in to consideration when developing your SWMS.

References: Australian Worksafe Standard for Plant (NOHSC:1010-1994) and AS4024 Revised January, 2017

Authorised and signed by Operator/Safety Officer: _______________________ Installer:_______________________

Loading...

Loading...