PAGE 48 — MAYCO LS450 CONCRETE PUMP • OPERATION MANUAL — REV. #2 (02/23/21)

The hydraulic system is factory-filled with Shell Tellus 46

hydraulic oil, typically used in ambient temperature ranges

of 39–90°F (4–32°C). The machine reservoir temperature

range is 100–170°F (38–77°C).

If the machine is used in areas with ambient temperatures

constantly above 90°F (32°C), the use of hydraulic fluid

designated with an ISO rating of 68 is recommended. In

areas with ambient temperatures constantly below 32°F

(0°C), use oil with an ISO rating of 32.

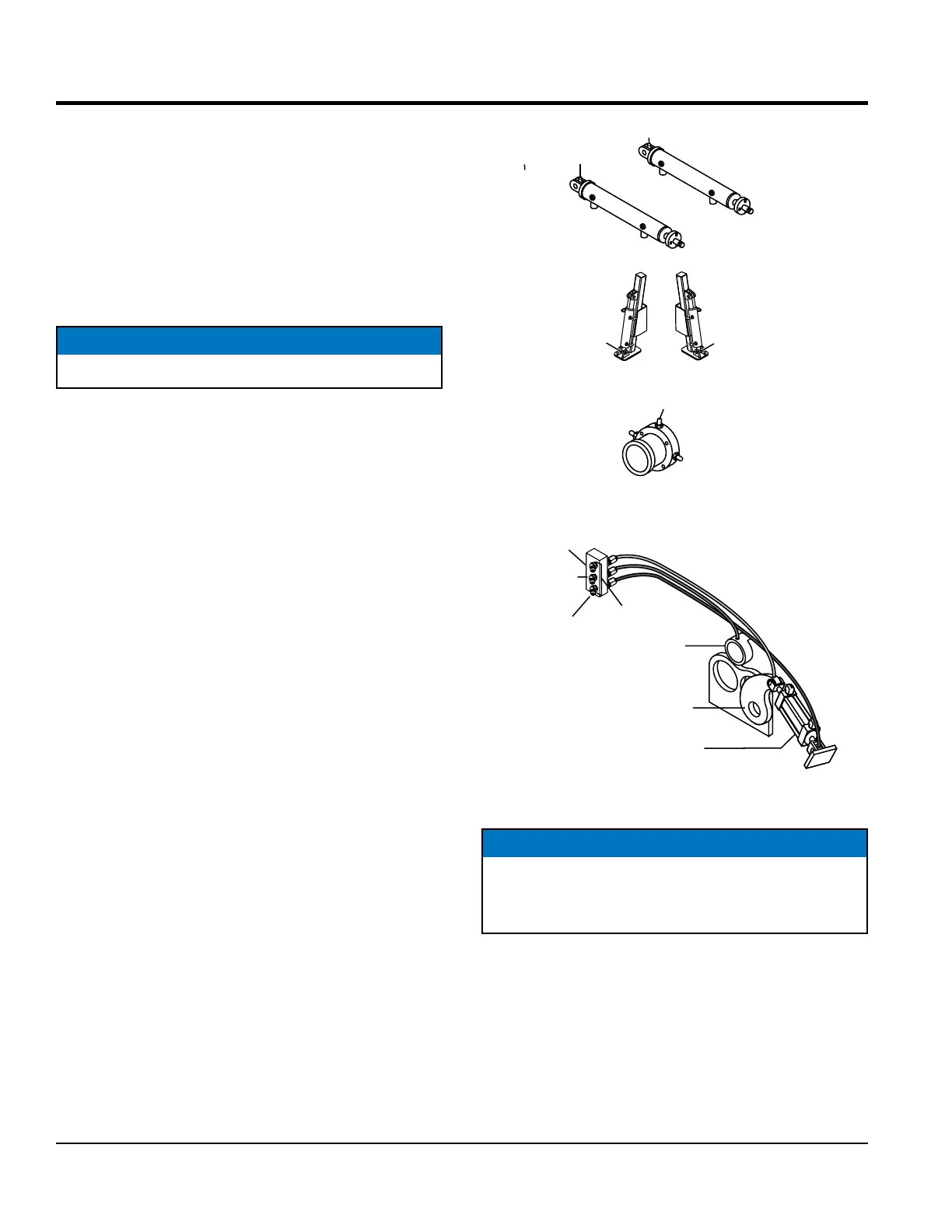

PUMP LUBRICATION

The following components should be greased daily (or

hourly if necessary). See Figure 54.

Main hydraulic cylinders (2 grease fittings)

Swing axle bushing (1 grease fitting)

Shuttle cylinder (2 grease fittings top and bottom)

Discharge nipple (3 grease fittings)

Outriggers option (2 grease fittings)

NOTICE

DO NOT mix oil brands! This may impair quality.

MAINTENANCE

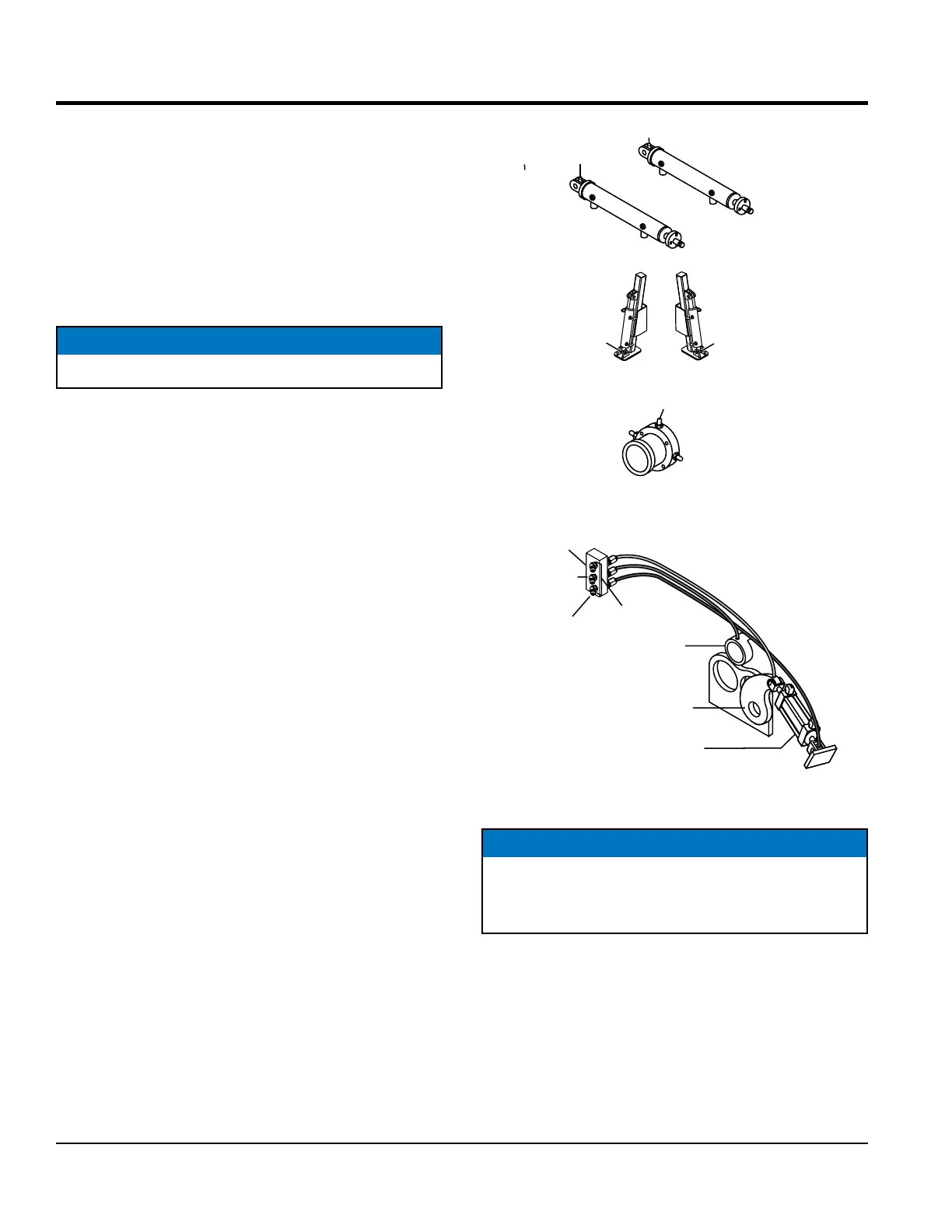

Figure 54. Lubrication Points

OUTRIGGERS

LEFT

RIGHT

SWING AXLE

BUSHING

SHUTTLE

CYLINDER

AXLE

CRANK

GREASE

POINTS

SHUTTLE

CYLINDER

TOP

SHUTTLE

CYLINDER

BOTTOM

SWING AXLE

DISCHARGE

NIPPLE

GREASE

POINTS (3)

GREASE

POINT

GREASE

POINT

CYLINDER

“B”

CYLINDER

“A”

GREASE

POINT

GREASE

POINT

NOTICE

When lubricating the above components, use

lithium-based EP, Texaco Multifak 20 or Lubriplate

ED-2 type grease.

Loading...

Loading...