MAYCO LS450 CONCRETE PUMP • OPERATION MANUAL — REV. #2 (02/23/21) — PAGE 49

CYLINDER LUBRICATION BOX

1. The lubrication level should be checked every day prior

to pumping and maintained at a height of 5 inches, or

about 1/2 the concrete cylinder height. We recommend

using a 30-weight motor oil.

2. As the rubber piston cups naturally wear, fine cement

particles will accumulate in the box. Once the concrete

paste reaches a height of about 1/2 inch from the

bottom of the box, drain and clean the lubrication box.

Cleaning the Lubrication Box

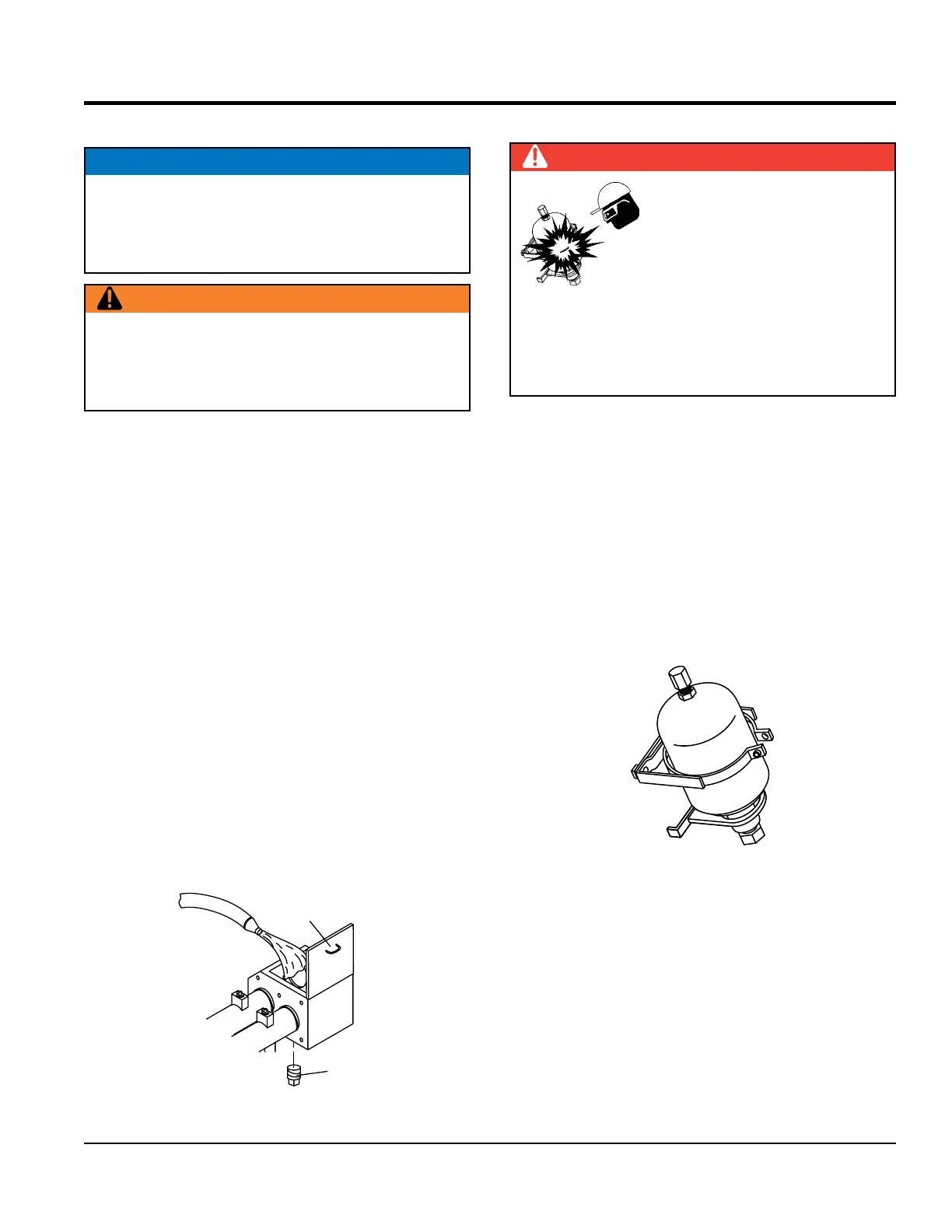

1. Remove the top cover and the drain plug (Figure 55)

located at the bottom of the box, and fully drain the

inside of the box.

2. Once the box is drained, start the engine and stroke the

cylinder (keeping hands out of the box) 10 to 15 times.

3. While stroking, spray water inside the box (Figure 55)

to thoroughly clean out all contamination.

4. When the box is clean, replace the drain plug, add new

lubrication and install the top cover.

Figure 55. Cleaning the Lubrication Box

NOTICE

When using the pump during freezing conditions,

completely drain the lubrication box and cover the

hopper after pumping. Frozen liquid will restrict the

piston travel and cause severe damage to the pump.

WARNING

ALWAYS follow lockout/tagout procedures before

checking the lubrication level. Stop the engine and

remove the engine starter key. The possibility exists of

severe bodily harm when hands are placed inside.

PLUG

TOP

COVER

W

A

T

E

R

MAINTENANCE

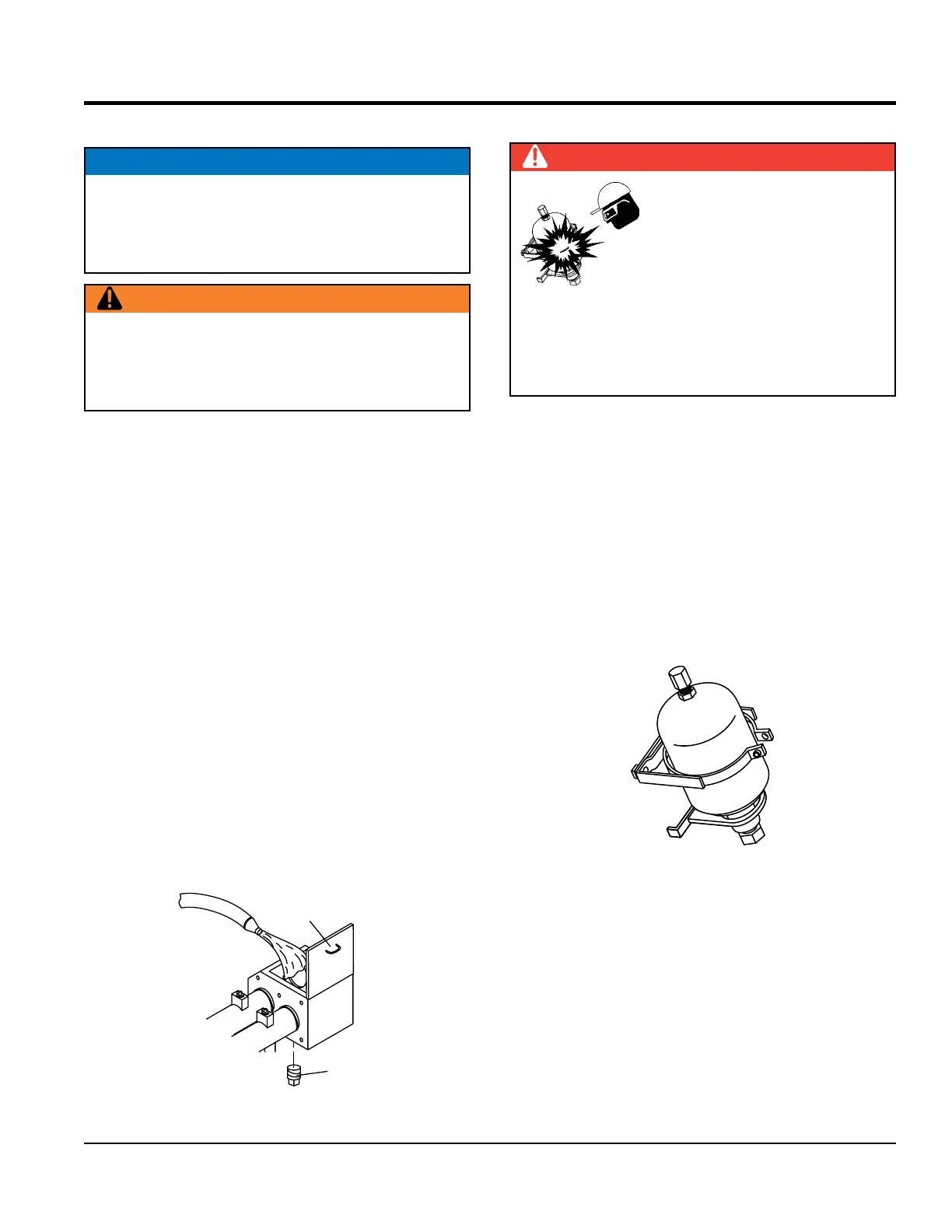

ACCUMULATOR CIRCUIT

The accumulator circuit has two functions within the

hydraulic system:

The accumulator circuit furnishes the hydraulic pressure

to cycle the shuttle tube.

The accumulator circuit also furnishes the pilot pressure

necessary to activate the hydraulic system.

The accumulator circuit is equipped with a bladder-type

accumulator (Figure 56) pre-charged with 1,100 psi of dry

nitrogen. The accumulator stores one gallon of hydraulic

oil which is under 1,750 psi of pressure.

Figure 56. Accumulator

When the pump cycles, a portion of the stored oil is

released to the shuttle cylinder. This released oil pressure

ensures that the shuttle tube has enough force to shear the

cylinder of concrete passing from the concrete cylinder to

the concrete delivery line during the cycle phase.

DANGER

Improper accumulator charging

can result in an explosion

causing serious injury or

DEATH! NEVER use oxygen

or compressed air to charge

the accumulator! Only qualified

personnel should perform this procedure. Use only

dry nitrogen to charge the accumulator. Contact

your Mayco service department or your local Hydac

representative for proper charging procedure.

Loading...

Loading...