PAGE 50 — MAYCO LS450 CONCRETE PUMP • OPERATION MANUAL — REV. #2 (02/23/21)

MAINTENANCE

Checking Accumulator Bladder Pressure

The normal accumulator pre-charge pressure should

be approximately 1,100 psi. To check the accumulator

pressure:

1. Start the engine and stroke the pump. The accumulator

pressure gauge (Figure 57) should read 1,750 psi.

Figure 57. Accumulator Pressure Gauge

2. To determine the actual accumulator pressure, stop

the engine and observe the pressure gauge. As

the pressure reading slowly decreases, it will reach

a point where there will be a sudden drop in the

pressure. The pressure reading should be taken just

prior to this sudden drop. If you do not read 1,100 psi,

the accumulator may require charging or bladder

replacement.

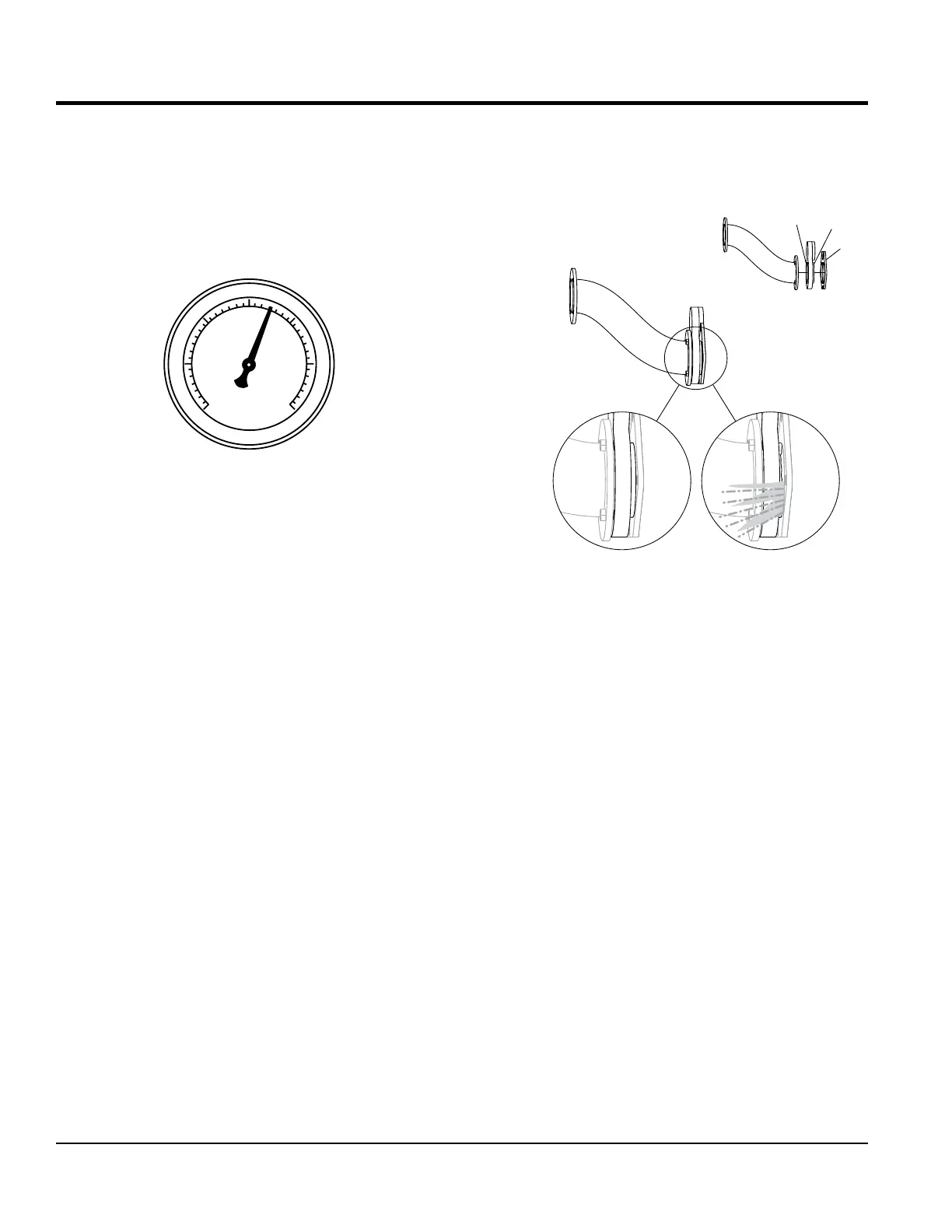

WEAR PLATE AND CUTTING RING

Due to the abrasive nature of concrete, it is normal for the

cutting ring to wear on its sides as it shears through the

concrete inside the hopper. The metal-to-metal friction and

the abrasiveness of the concrete will cause extreme wear

and reduced sealing capability between the cutting ring

and wear plate.

If the two components do not properly seat against each

other, slurry will pump into the hopper rather than out of

the discharge line. See Figure 58. This condition can be

easily observed:

The level of concrete inside the hopper changes

suddenly during each pumping stroke.

Concrete slurry squirts into the air from the hopper

(volcano effect).

0

ACCUMULATOR

500

1000 2000

3000

2500

1500

The output volume at the end of the delivery line

decreases in pressure.

Frequent, unusual material packs in the shuttle tube.

Figure 58. Wear Plate and Cutting Ring

It is important that the wear components be inspected

weekly for proper sealing. Failure to inspect will eventually

cause severe damage to the nun plate and material

cylinders. Visually inspect the wear plate and cutting ring

to ensure surfaces are sealed against each other.

If a deep groove or a wide space has developed on the

sealing surfaces, it is time for replacement. Due to the

motion of the shuttle tube, the cutting ring experiences

a quicker rate of wear as opposed to the wear plate. The

wear ring typically requires replacement two times per wear

plate (2 to 1). When replacing the wear ring, also replace

the rubber energizer ring.

Changing the Concrete Cylinder Piston Cups

The urethane piston cups will occasionally require

replacement depending on the following factors.

The fluid level and cleanliness of the lubrication box.

The size and type of aggregate.

The type of concrete being pumped.

It is time to replace the cups when increasingly large

particles of sand and cement pass into the lubrication box.

GOOD SEAL LEAKING

SHUTTLE TUBE

(INSIDE HOPPER)

RUBBER

ENERGIZER

WEAR

PLATE

CUTTING

RING

Loading...

Loading...