Instruction manual – MU-C/S 7

3. Necessary maintenance

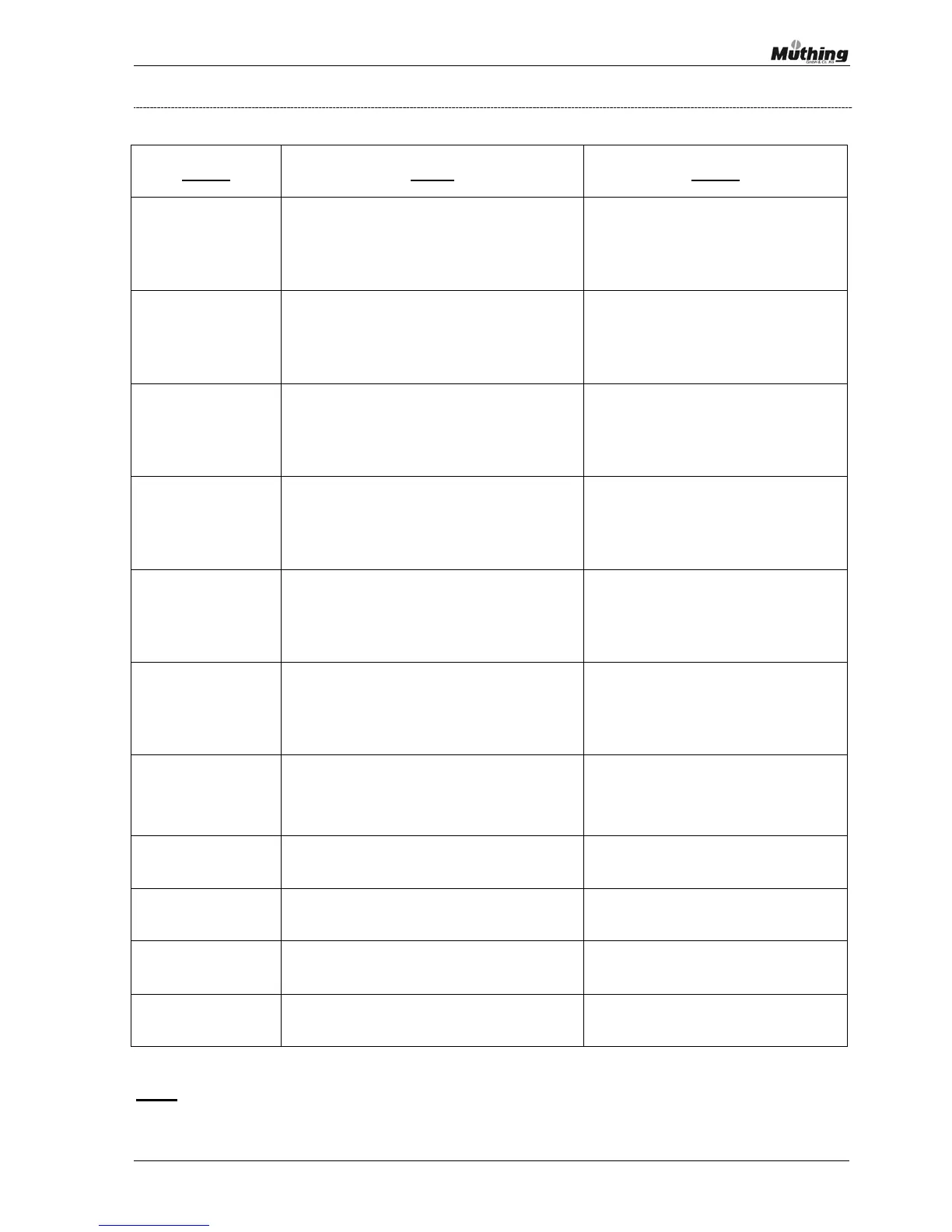

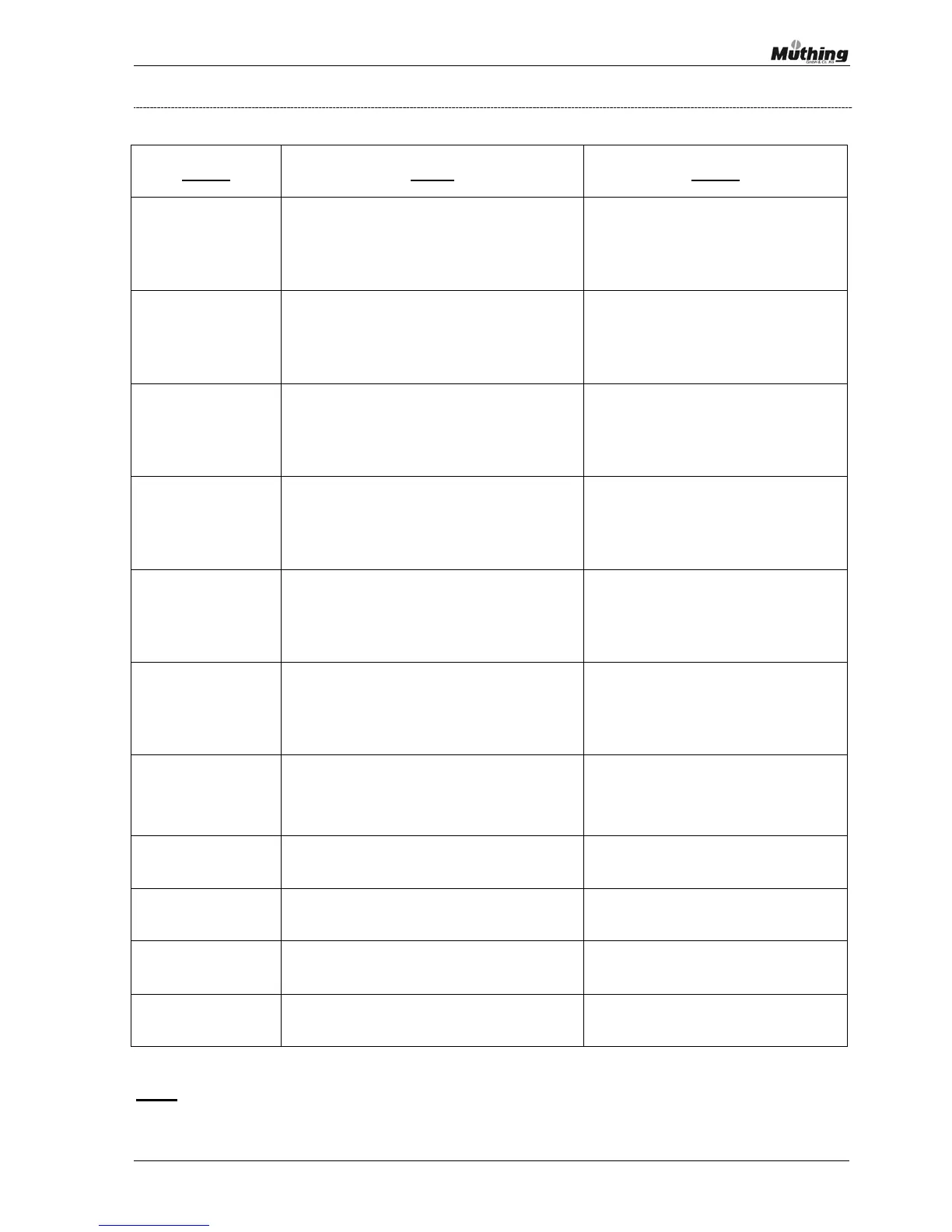

When What Notes

At least every 4

hours of operation

Grease the rotor- and back-up roller

bearings on both sides

via the grease nipple with normal lithium

lubricating grease

The grease must be seen to

emerge when you lubricate the

back-up roller bearings – Give the

rotor bearings 4 to 5 squirts on

each side

Daily Grease rotor or landwheels

If wheels are in use instead of the

support roller

Daily

Grease or lubricate sideshift mechanism

and grease points on support arm

If machine can be side-shifted

Daily Service and lubricate P.T.O. shaft

Adhere to P.T.O. shaft

manufacturer’s operating and

maintenance instructions

After 30 to 40

operating hours

Carry out first gearbox oil change

Only use SAE 90 EP

or SAE 140 transmission oil

Every 200

operating hours, at

least once a year

Carry out oil change in gearbox

Only use SAE 90 EP

or SAE 140 transmission oil

Regularly

Check gearbox oil level and top up if

necessary

Only use SAE 90 EP

or SAE 140 oil

Regularly Check drive belt tension Retighten as necessary

Regularly Retighten nuts and bolts

Replace unusable and worn nuts

and bolts

Regularly

Check protection devices and ensure

that they function

Replace defective appliances

Regularly Tool and equipment check

Replace defective tools with nuts

and bolts, repair device

Note:

Reattach and secure all protection devices after carrying out maintenance or repairs.

Loading...

Loading...