Instruction manual – MU-C/S 51

10 Malfunctions, causes and remedies

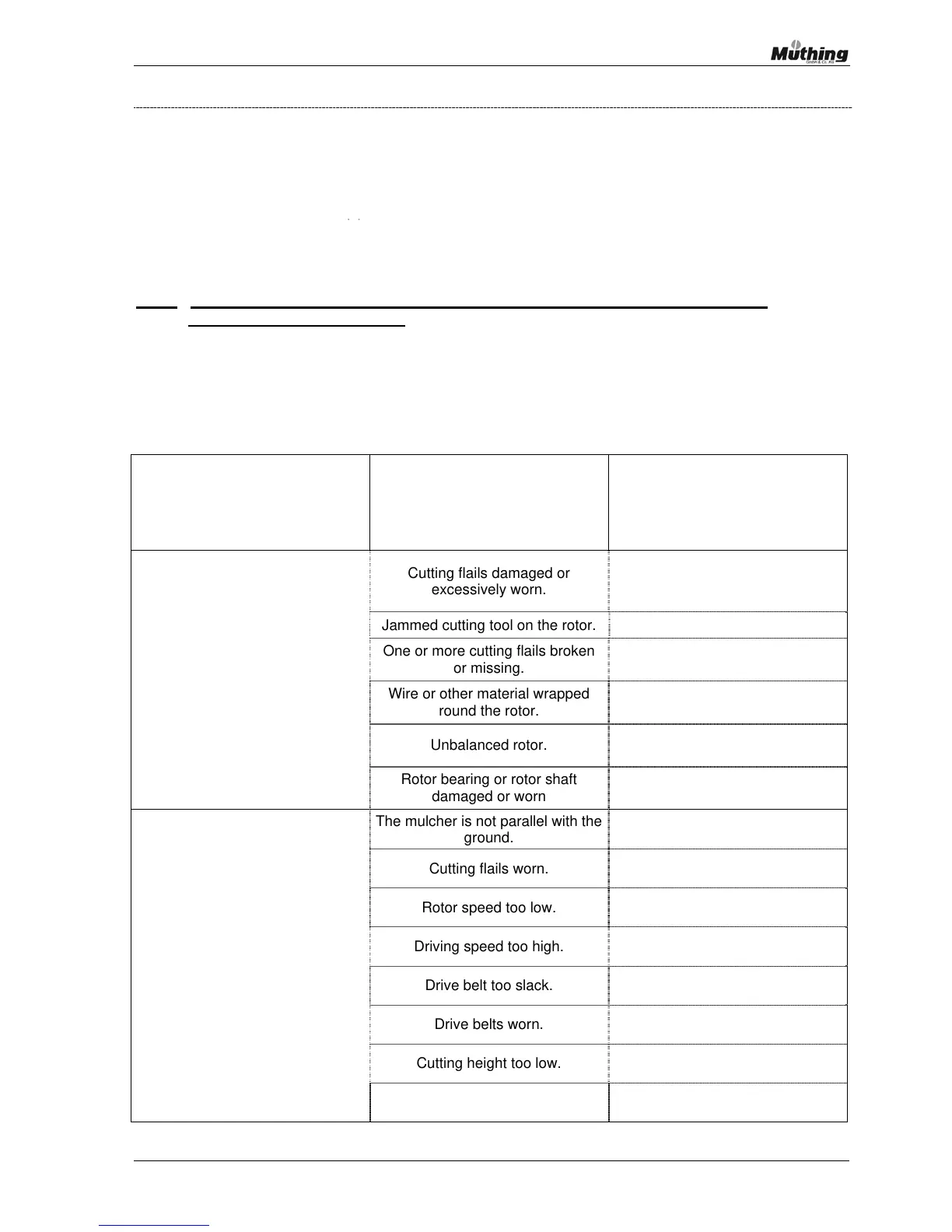

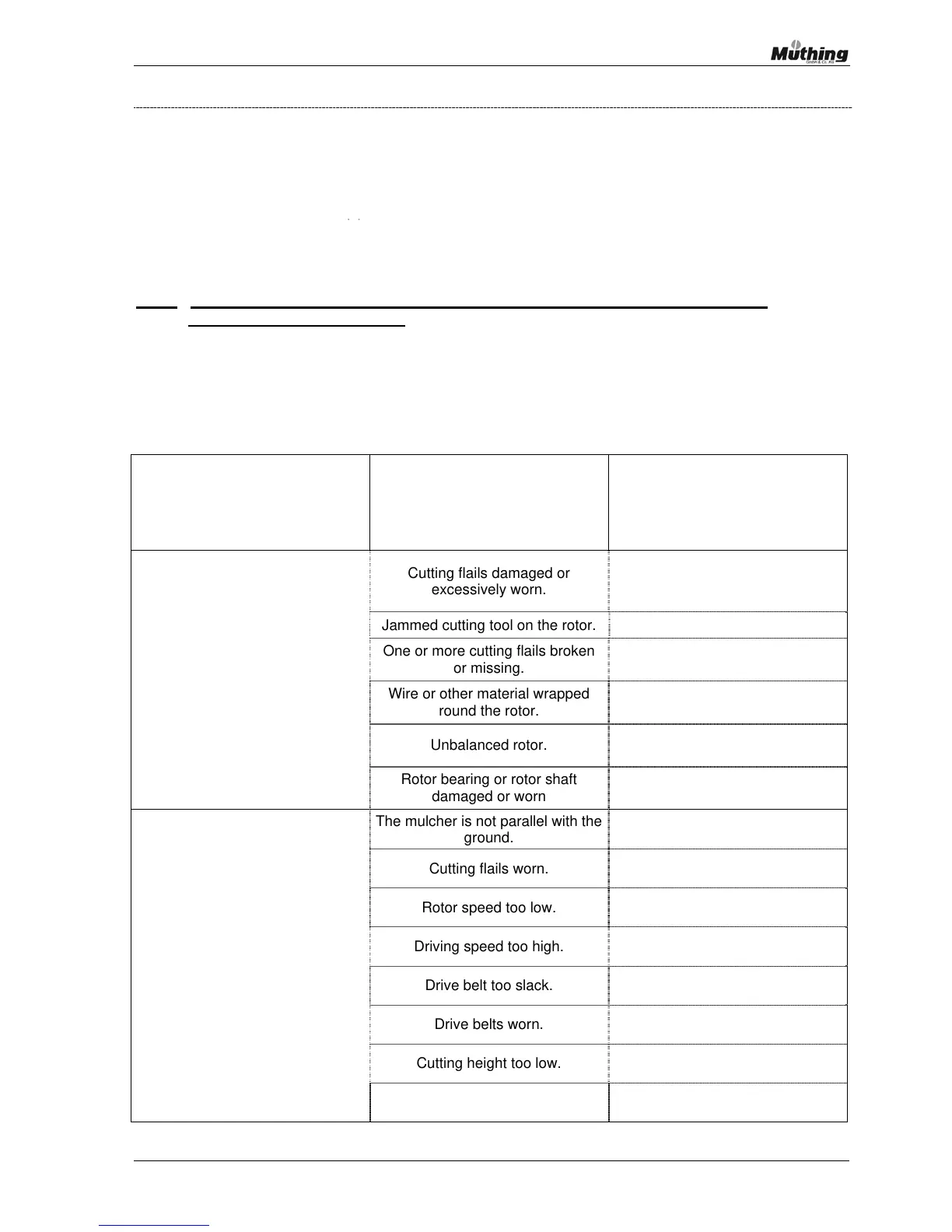

The table below contains a list of faults that we have collected in the course of our experience with

mulchers, the possible causes of these faults and the action that you should normally take to

resolve the problem.

If our recommended action fails to cure the fault or further problems arise please contact your

supplier. This will help us to get to the root of the problem and find a suitable solution. We shall use

the experience gained from this information to make further improvements to the mulcher.

Note: Please note the safety instructions, details of risks and accident prevention

regulations on pages 16 -26!

Fault Cause

Solution

Cutting flails damaged or

excessively worn.

Change the worn cutting flails

including mounting nut and bolt in

pairs or as a complete set

.

Jammed cutting tool on the rotor. Clean cutting tool mounting.

One or more cutting flails broken

or missing.

Replace cutting flails.

Wire or other material wrapped

round the rotor.

Remove debris.

Unbalanced rotor.

Check the weighting and

rebalance as necessary.

The mulcher emits excessive

vibration and noise

Rotor bearing or rotor shaft

damaged or worn

Replace the bearing or shaft.

The mulcher is not parallel with the

ground.

Adjust the toplinkage until the

mulcher is sitting correctly.

Cutting flails worn.

Change the worn cutting flails

including mounting nut and bolt.

Rotor speed too low. Increase rotor speed.

Driving speed too high. Drive more slowly

Drive belt too slack.

Check drive belt tension and if

necessary retighten.

Drive belts worn.

Replace complete set of drive

belts.

Cutting height too low.

Lower the support roller/wheels

and /or adjust the toplinkage.

Mulcher operation

and/or

cut unsatisfactory

Cutting height too high.

Raise the support roller/wheels

and /or adjust the toplinkage.

Loading...

Loading...