Maintenance 23

3 Maintenance

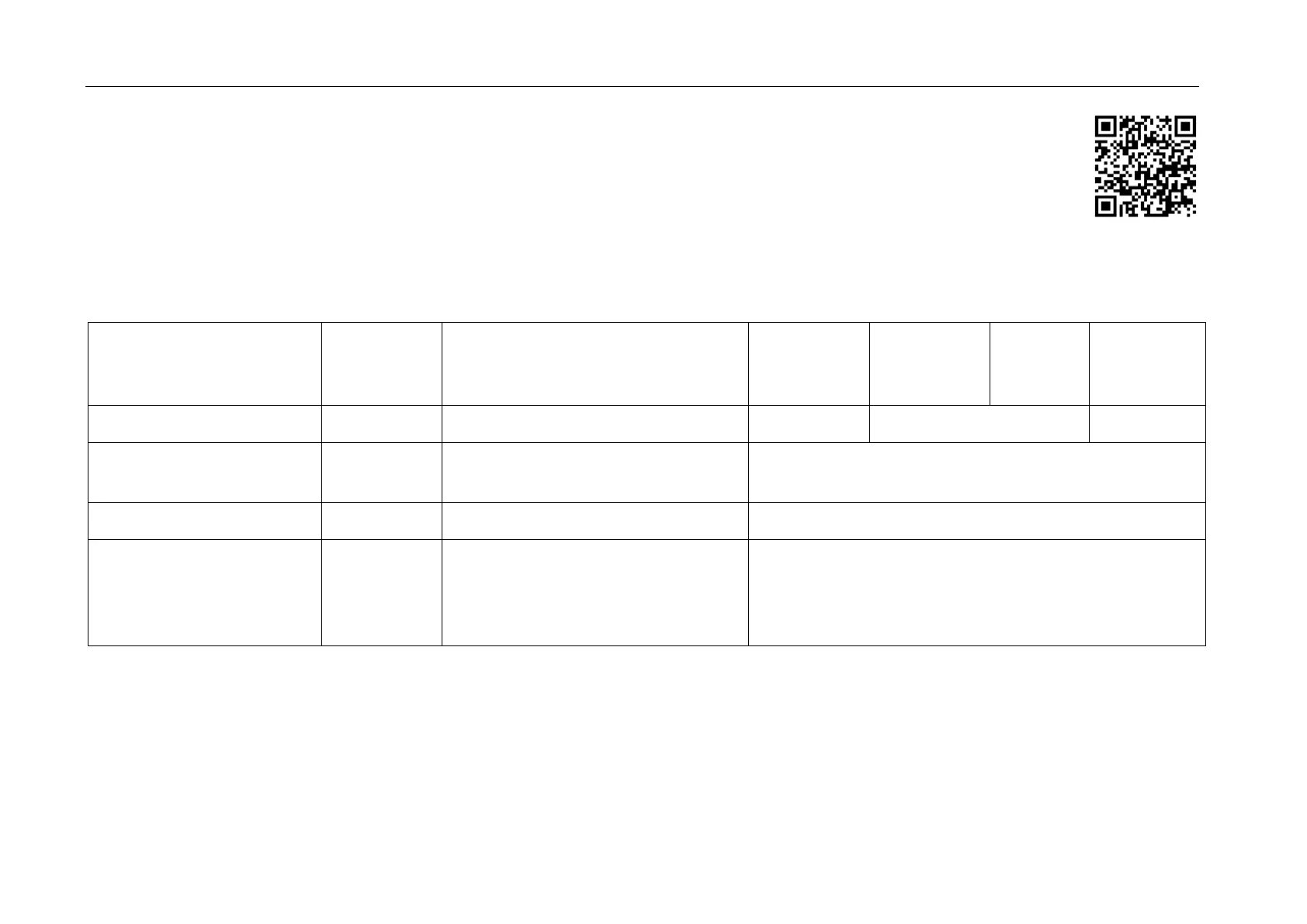

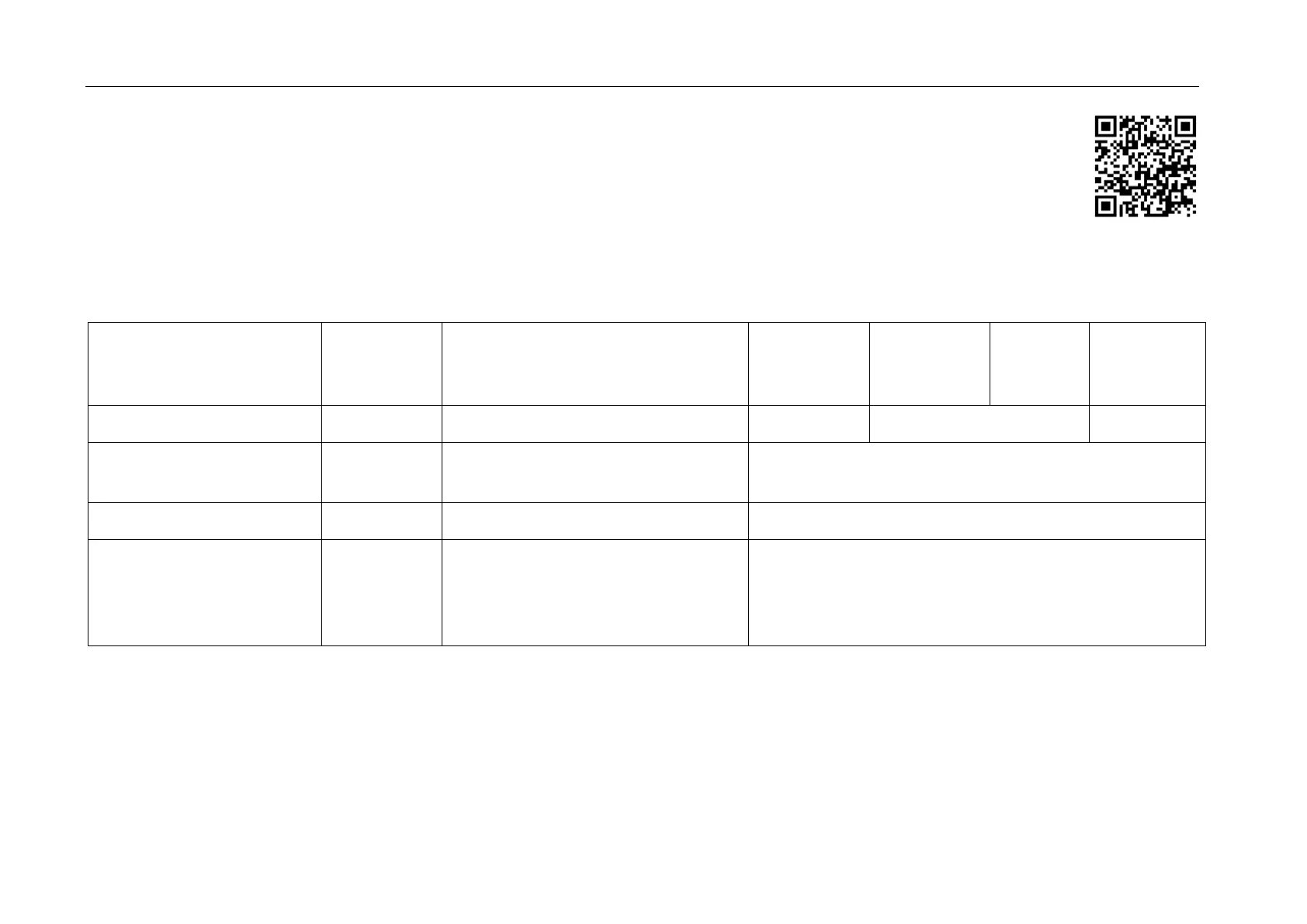

3.1 Maintenance concept – Overview of maintenance activities

The following WMF maintenance concept based on time-/serving-dependent cycles, describes the minimum scope of maintenance activities as recommended by

WMF. Please also take into account the special terms arising from the service agreements and local factors (which may make earlier descaling of the flow heater

necessary).

Abbreviation

Maintenance

package

Extended steam boiler and boiler

inspection

1 x annually or after service life interval

Due date:

without water filter > after adjustment of

degree of hardness

with water filter > 1 x annually

2 bottles of WMF liquid descaling agent 33 7006 2869

1) The following options require additional installation as part of service maintenance 2:

Fresh Filtered Coffee: O-Ring 33.1523.3100 and O-Ring 33.0397.0000 at tube connector

FFC (machine modell with one switching valve): valve body 33.4190.4000 and membrane 33.4190.3000

Dynamic Milk with FFC (machine modell with two switching valves): valve body 33.4190.4100 and membrane 33.4190.3000

In addition, an extended inspection of the boiler and steam boiler MUST take place for technical safety-related reasons as part of service maintenance 2

(as with the presto family).

* For details on the contents of the maintenance packages please see the following pages

Loading...

Loading...