61

REPLACING THE FUEL FILTER

NOTE !

To ease up the air bleeding during fuel lter replacement,

the lter assembly may be lled with some fuel, only if

you are sure not to spill any.

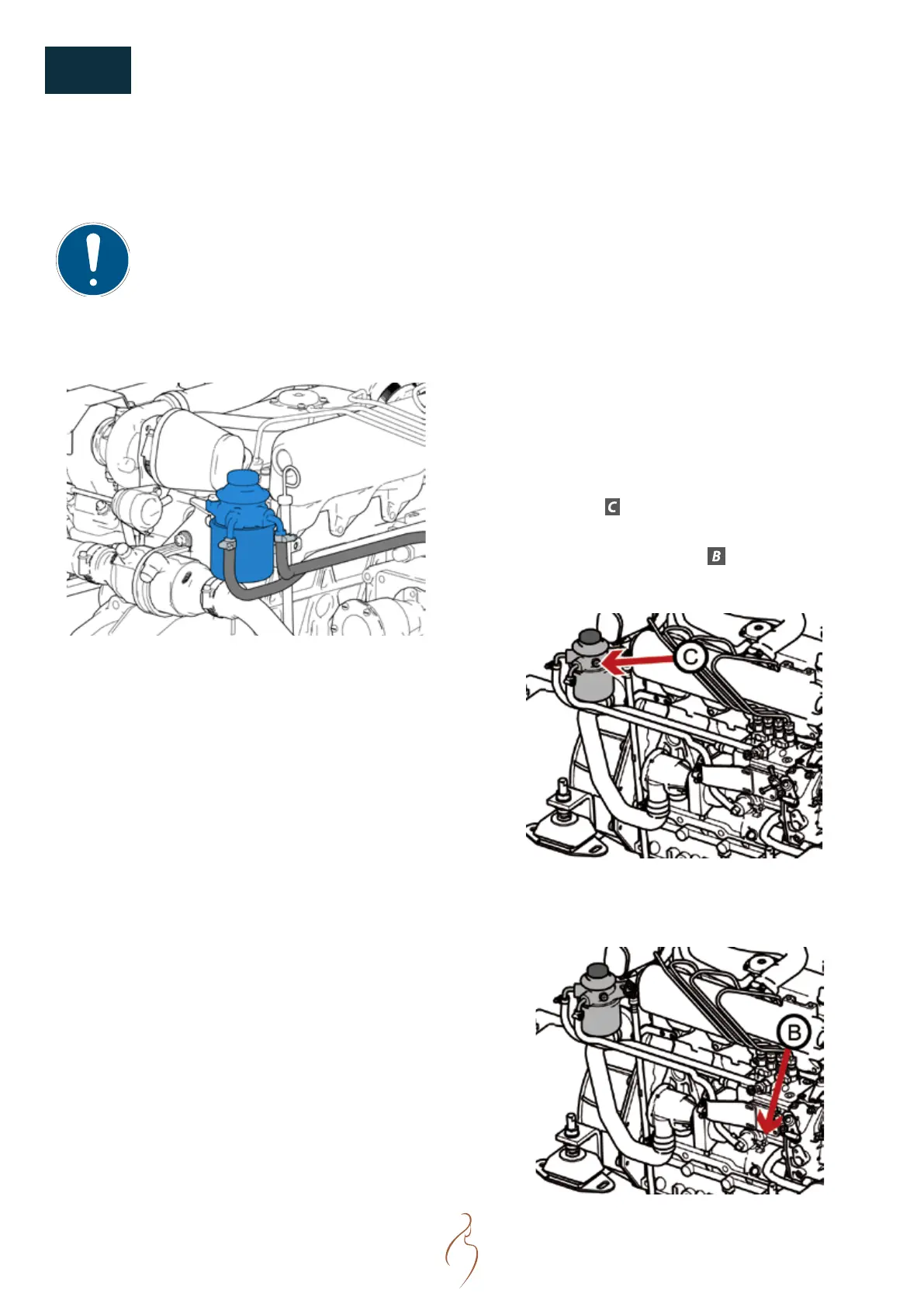

Above picture : fuel lter assembly

1. Close the fuel butterfly (control) valve. Wipe up the

holding lter bracket with a clean non flint cloth.

2. Remove the protective tank.

3. Put a plastic bag over the lter to prevent spills on

the engine.

4. Remove the fuel lter. Use a lter wrench tool if lter

is seized.

5. Check and clean the sealing surface of the lter

bracket. Apply a thin lm of fuel onto the seal.

6. Screw the new lter by hand until the seal is flush

with the matting surface. Thight up a further half

turn.

7. To bleed the air in the fuel system, see next paragraph

for complete explanations.

S08 MAINTENANCE

AIR BLEEDING

Bleeding the air in the fuel system might be required :

• After a maintenance operation on the fuel system.

• If the fuel tank has been emptied.

• The engine has not been started for a long time.

TO BLEED THE FUEL SYSTEM FITTED WITH THE

STANDARD MECHANICAL PUMP :

1. Fill up completely the fuel tank. Open the fuel valve.

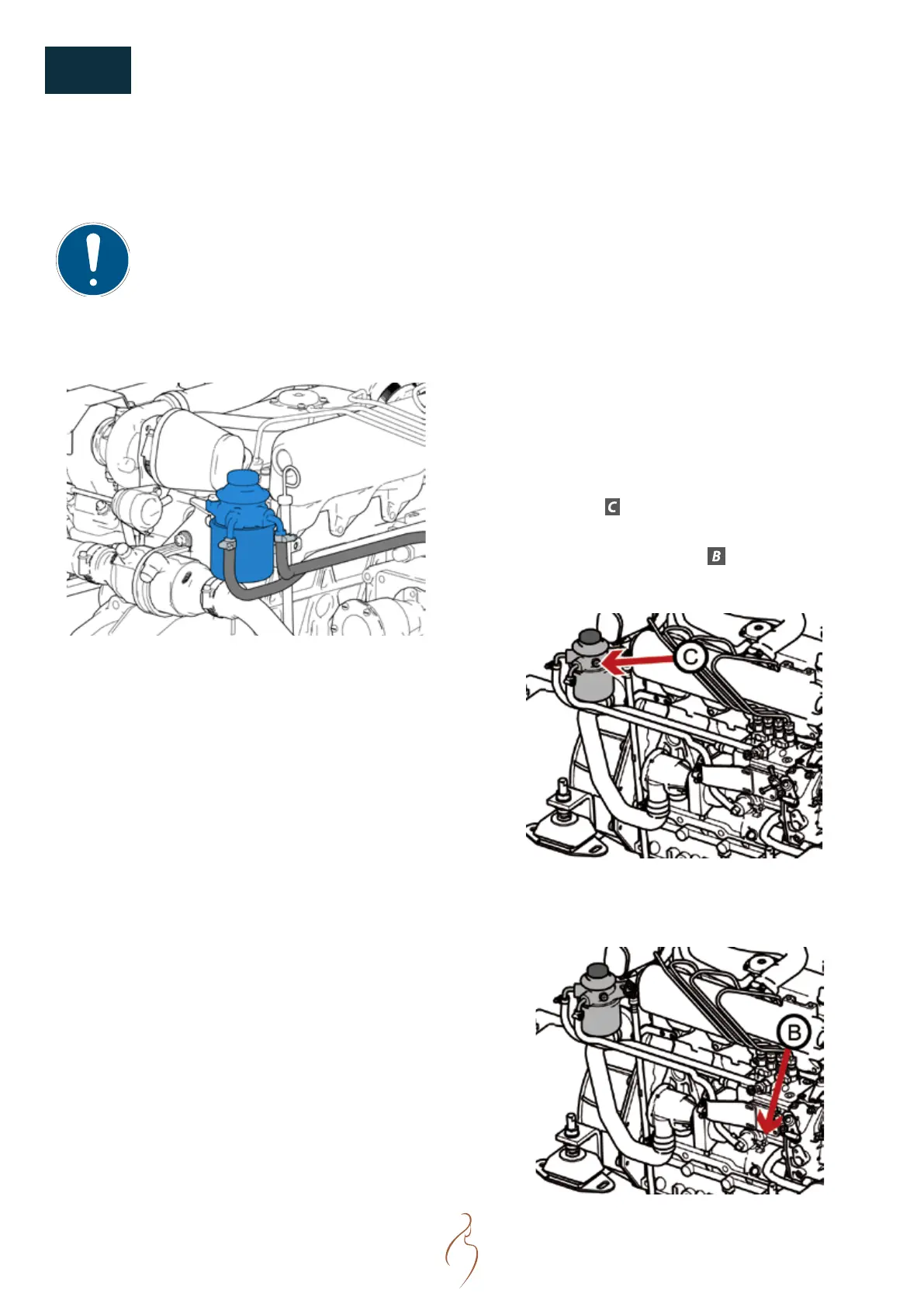

2. To avoid spills, Dispatch a non flint cloth around the

venting screw

of the fuel lter holder and loose it

up (see picture below).

3. Pump the fuel using the lever

from bottom picture

back and forth until fuel free of air bubbles flows out

of the venting screw.

4. At this stage, you can tighten the venting screw.

5. Pump a few more times to make sure to prime

completely the system.

Loading...

Loading...