NDW | We’ll keep you rolling | 14

NDW | We’ll keep you rolling | 15

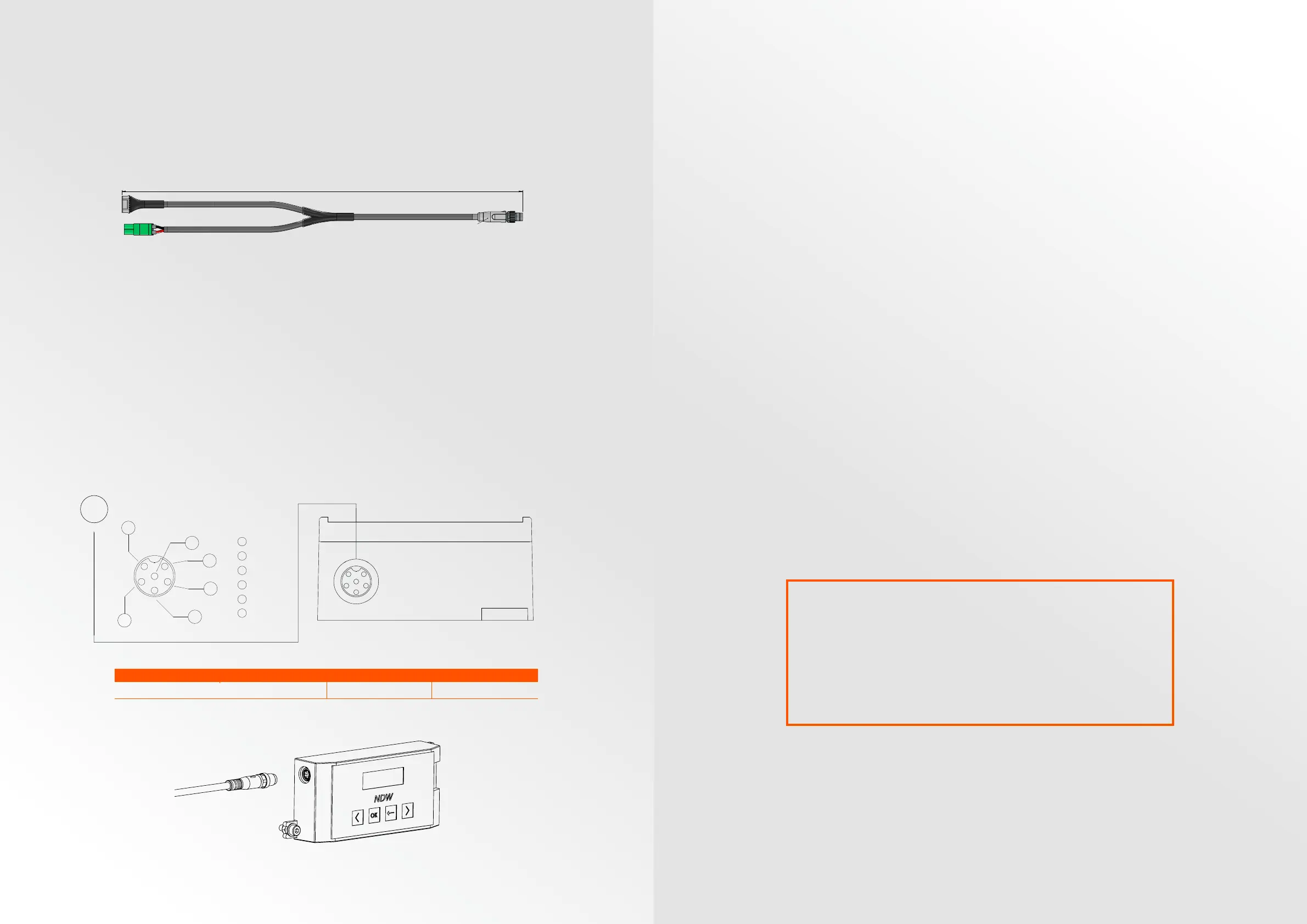

M8-5pin Adapter cable

If desired, it is possible to order an adapter cable that combines the 24V

power and communication cable to a standard M8-5pin connector which

allows for integration with existing electrical infrastructure and control

platforms (i.e. ASI, B&W, P&F, MOLEX etc).

Order code: 901-ADP-B-SC/SN. A full overview of accessories is shown on

page 27. For more information, please contact NDW.

Connection of the NDW E-roller

The NDW motorized E-roller can directly be plugged into the BC50 controller.

Use the screw connection to fixate the cable.

If required, the cable of the E-roller can be extended using NDW motor

extension cables. Order code: 901-CABMOT-L. Only use original NDW motor

extension cables since they guarantee the required ratings.

The “L” stands for required length. Available in dierent standard lengths. A

full overview of accessories is shown on page 27.

NOTE: The total length of the E-roller cable may not exceed 6 meters.

Only connect the E-roller when the controller has no power.

310

Available in two configuration:

- M8 screw connection (901-ADP-B-SC)

- M8 snap-in connection (901-ADP-B-SN)

Pin No. 2

Pin No. 5

Pin No. 3

Pin No. 1

Pin No. 1

Pin No. 4

Pin No. 1

Front view of COM connector

Front view of PWR connector

*Required speed must be set on the NDW controller

Front view of M8 connector

Pin No.

Color

Function

1

Green

Off / Spd 1

2

Orange

Spd 2 / Spd 3

3

White

Direction

4

Black

Error

5

Blue

Ground

6

Red

Digital A

7

Yellow

Digital B

Pin No.

Color

Function

1

Red

24V+

2

Black

0V-

Pin No.

Function (901-ADP-B-SC)

Function (901-ADP-B-SN)

1

24V+ 24V+

2

Direction Direction

3

0 V- 0V-

4

Start/Stop (24V+)

Error output

5

Not Used

Start/Stop (24V+)

Surface finish:

Deburr and break all sharp edges

NAME

DATE

Material:

3D file is leading

Revision:

Title:

Drawing name:

SCALE:1:2

SHEET 1 OF 1

A3

TvL

TvL

30/09/2019

30/09/2019

901-ADP-B

R01

Weight [kg]:

According to ISO 2768-mK unless

specified otherwise

Drawn by

Checked by

Tolerances:

All units are in mm unless specified otherwise

Remarks

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

Type Connector Cable specification Remarks

E-Roller cable M8-6pin screw

6x0.25 mm²

-

1

1

5

6

3

4

2

1 24V

2 Speed feedback

3 Direction

4 0V

5 Speed control

6 Run / Stop

Motor Connection

1

1

5

6

3

4

2

1 24V

2 Speed feedback

3 Direction

4 0V

5 Speed control

6 Run / Stop

Motor Connection

Surface finish:

Deburr and break all sharp edges

NAME

DATE

Material:

3D file is leading

Revision:

Title:

Drawing name:

SCALE:1:1

SHEET 5 OF 5

A3

TvL

TvL

19/09/2019

19/09/2019

BC50_Asm_R02

R01

Weight [kg]:

According to ISO 2768-mK unless

specified otherwise

Drawn by

Checked by

Tolerances:

All units are in mm unless specified otherwise

Remarks

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

INITIAL STARTUP AND OPERATION

Checks before initial start up

• Make sure that the BC50 controller is mounted correctly and that all the

screws have been tightened.

• Check the area around the controller and the motorized roller to make sure

there are no other components creating dangerous situations.

• Make sure that the wiring is in accordance with the specification and

legal directives.

• Check all protective measurements.

• Check if the motorized roller is properly mounted to prevent damage to the

motor cable due to rotation.

• Check the conveyor system and make sure no personnel stands in

hazardous areas.

Checks before operation

• Check the BC50 controller for visible damage.

• Check all protective measurements.

• Make sure there is no blockage of the E-roller.

• Check the conveyor system and make sure no personnel stands in

hazardous areas.

WARNING!

Accidental start-up of the E-roller

Hazardous situation for both personnel and goods. Make sure no

unauthorized persons are near the conveyor before switching on

the power supply.

Loading...

Loading...