32

1 2 3

F N

230V~ 50/60Hz

3

1 2

230V ~

-

+

24V

3

1

2

1 2 3

24V

After connecting the electricity supply to the control button (bipolar with arrows if possible),

check that the up key function opens the window frame and the and down key function

closes it. In the event that keys should function to the contrary, invert cable positions.

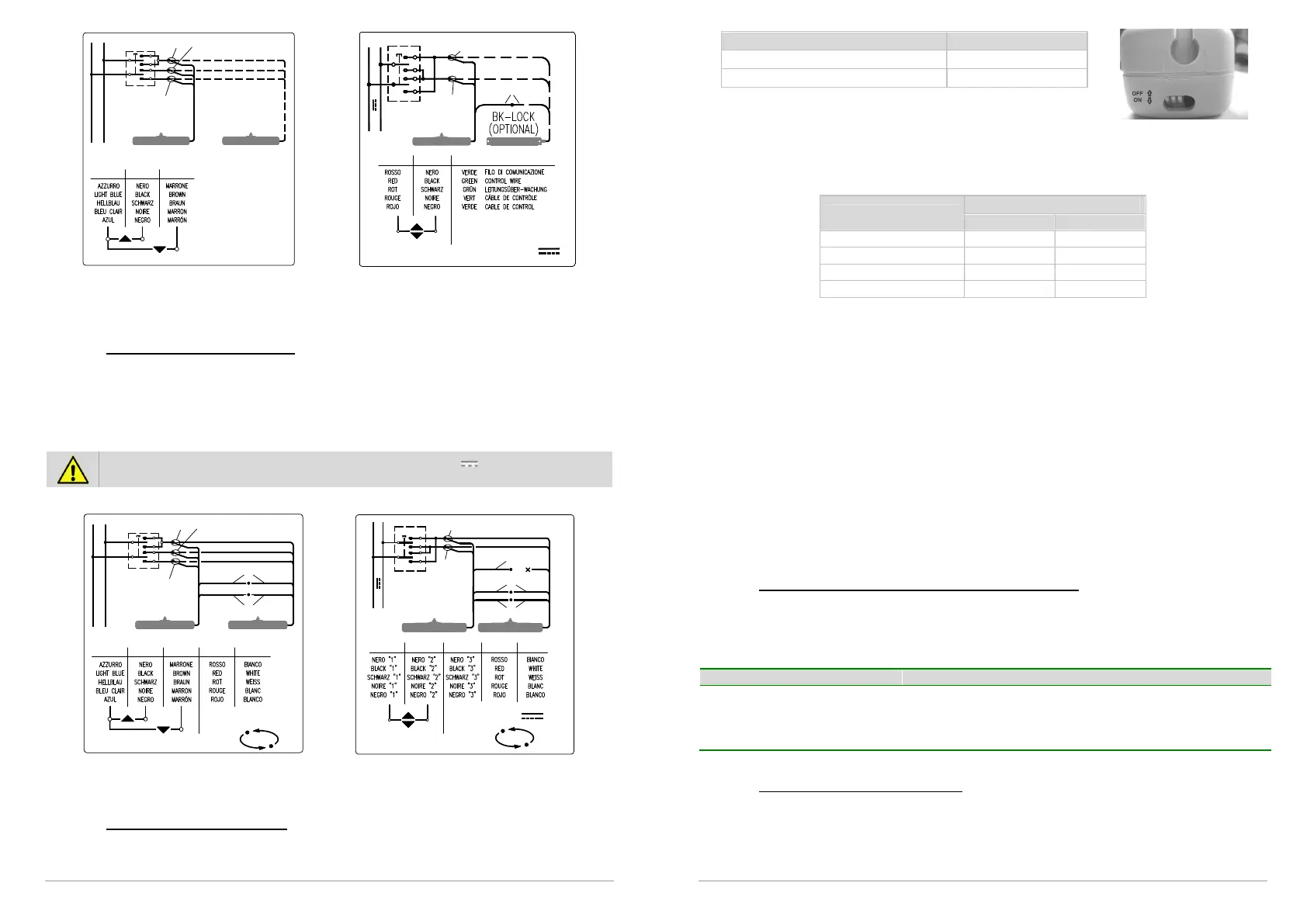

10.2. Connections of Kato Syncro³

Cable supplied together with actuator is 2,5 m (±5%) long and it is calculated in accordance

with safety rules. See table on page 27 for conductor section indications.

Electrical connection of cables white and red has to be done with a loose connector of proper

dimensions (clamp is on equipment). Fundamental importance has a steady connection, with a

good electrical contact because passing tension is very low.

IMPORTANT FOR PRODUCT SAFETY: on actuators with 24V supply voltage, Kato

Syncro

3

version, wire Black “3”, if not used, must be insulated.

For harness, please follow these diagrams:

1 2 3 4

F N

100-230V~ 50/60Hz

3

1

4

2

110/230V ~

SYN C RO

5

5

24V

+-

2

1

1 2 3

3

54

4

5

NC

24V

SYN C R O

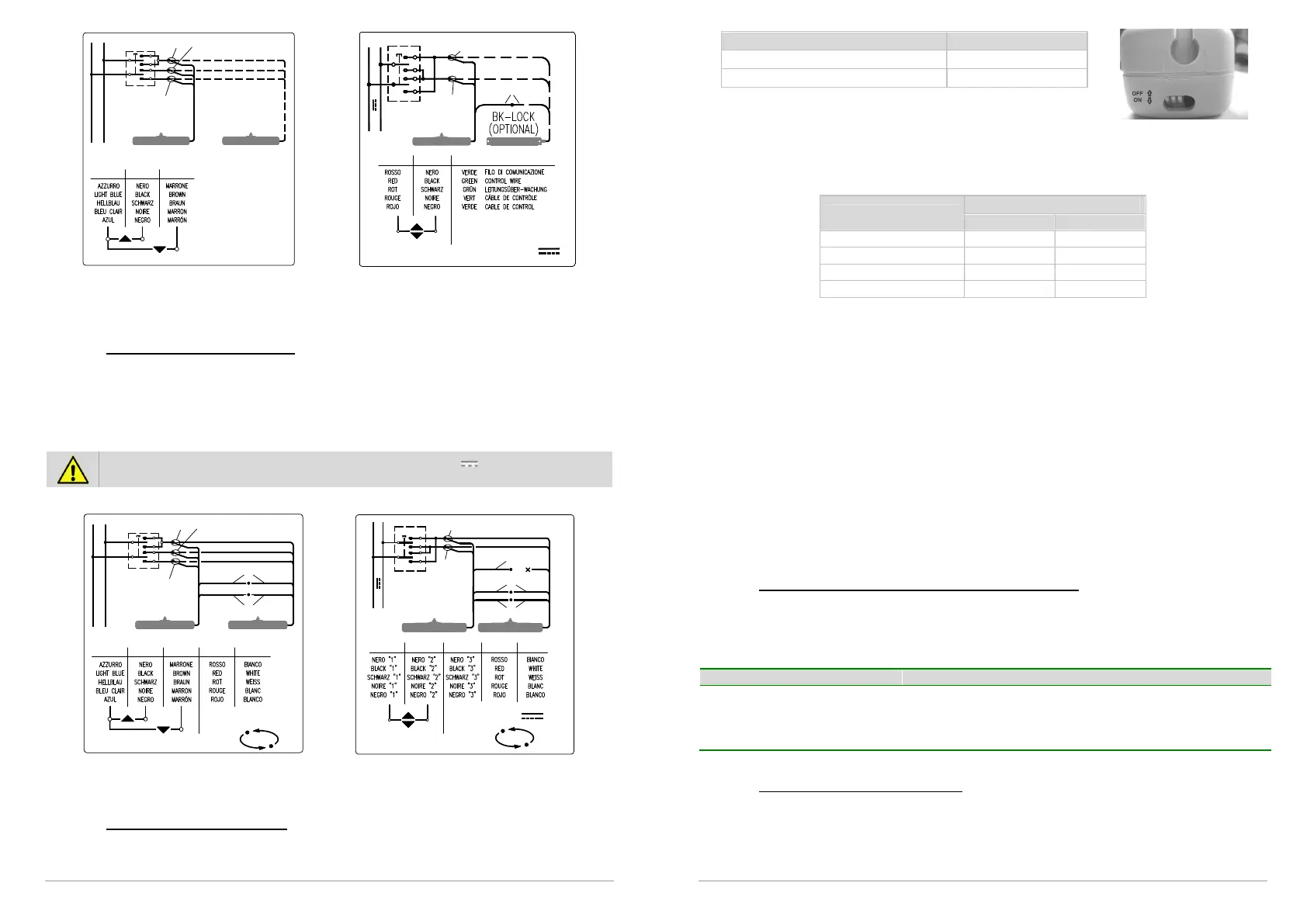

11. PROGRAMMING THE LIMIT SWITCHES

11.1. Programming Kato actuator

Electromechanical lock setting (only Kato 24V)

2 (two) positions can be selected, with or without electromechanical lock.

33

Mode DIP-SWITCH No. 3

With electromechanical lock ON

Without electromechanical lock OFF

Limit switches at opening

4 (four) positions can be selected for the limit switch of the outgoing chain. To program,

adjust the two dip-switches at the side of the LED. Programming is simple, immediate and

can be carried out at any time by adjusting the two dip-switches as indicated in the following

table.

Limit switches

Dip-Switch

Nr. 1 Nr. 2

110 mm OFF OFF

200 mm ON OFF

300 mm OFF ON

400 mm ON ON

After the limit switches have been programmed, run a few check manoeuvres. In the event of

error, programming can be repeated to give the desired track run.

Limit switches at closure

The limit switch at closure is automatic, electronically operated and cannot be programmed.

The actuator stops when the charge is absorbed when the window is completely closed and

the weather stripping is completely depressed. After each closure or intervention of the

electrical protection mechanism, the chain moves in the opposite direction for around 1 mm.

This is to loosen the tension of the mechanical parts and gives correct pressure to the

weather stripping.

When the window frame is closed, check that the chain terminal is at least a couple of

millimetres away from the actuator body.

This ensures proper closure for the window and ensures all weather stripping is sealed. If the

chain terminal is not positioned correctly there is no guarantee that the window will close

completely. Check that attachments and support brackets are firmly fixed to the window

frame and that all screws have been correctly tightened.

11.2. Luminous indications on led (only for Kato 230V)

Before activating the actuator, familiarise yourself with messages indicated by the red led

opposite the lead. This will allow you to check that the machine is functioning properly or

allow you to recognize possible irregularities. The LED is only visible when the actuator has

been turned on.

Constantly lit Motor in use.

Off and flashing Motor has regularly reached a limit stop but is still

connected to electricity supply.

Normal regular blinking Motor in electronic protection due to excessive charge

11.3. Programming the Kato Syncro³

The actuators leave the factory programmed and synchronized in pairs, thus the user only

needs to select the desired stroke. It is recommended that you check to ensure that all the

chains are in the same position and the actuators are connected properly as per paragraph

10.2. In the event the settings are lost, a new synchronization must be performed according

to the procedures described below.

Loading...

Loading...