1 Introduction Page 6

Stud welding unit operating manual Date: July 2021

ALPHA 850 07.2021 / EN Rev.: A

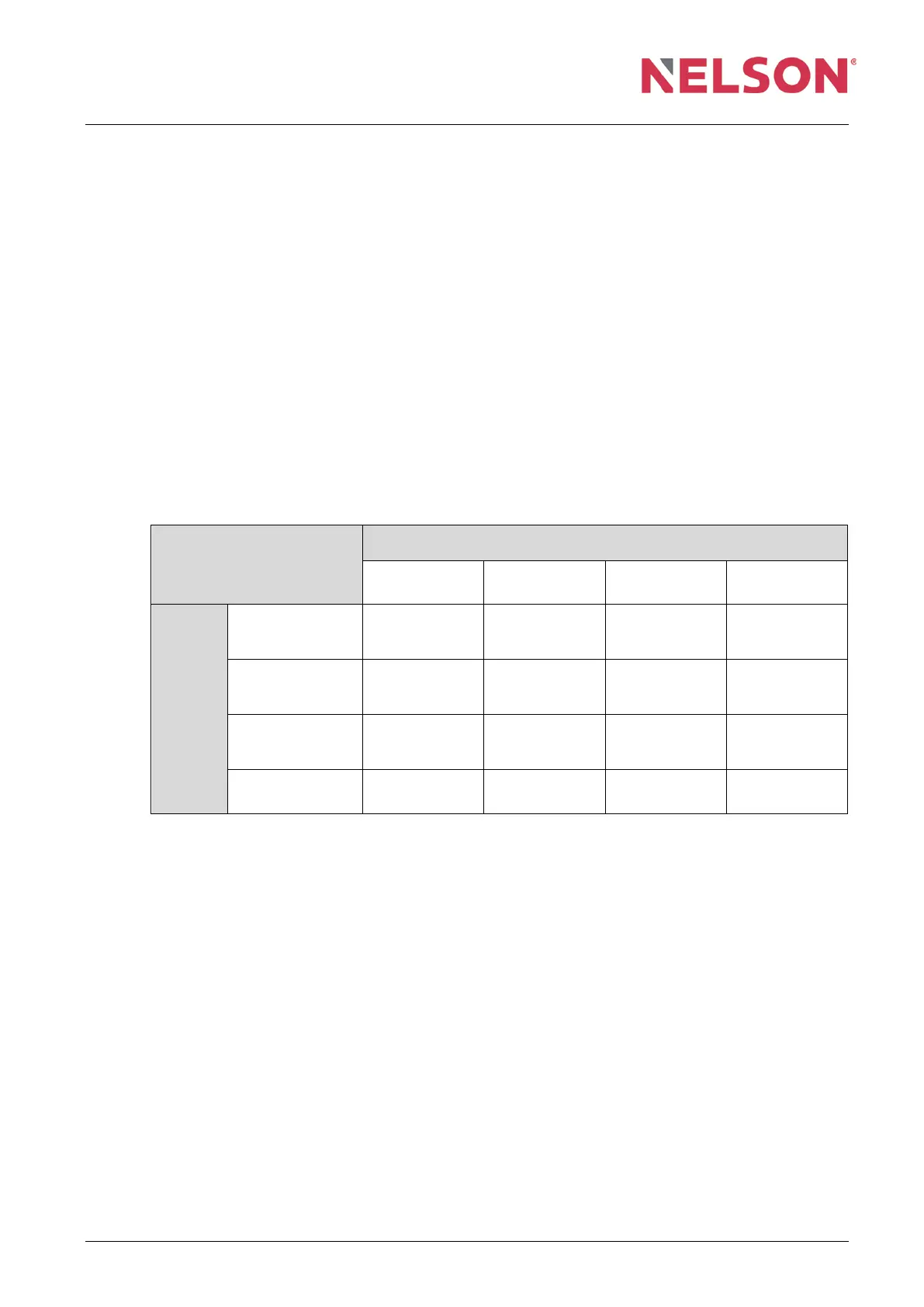

1.7 Material combinations

The material combinations listed in the table below have already been tested. The

weld angle for the material combinations is defined as follows:

a = suitable for any application, such as force transfer,

b = suitable with limitations for force transfer,

c = suitable with limitations only for heat transfer,

– = cannot be welded.

Explanation of superscript numbers:

1)

Up to 10 mm diameter and shielding gas in tub position (PA),

2)

Only during short cycle stud welding with drawn arc,

3)

Maximum yield strength R

eH

≤ 460 N/mm

2

.

Material

combination

Base material

EN ISO 15614-1

Groups 1 and 2

3)

EN ISO 15614-1

Groups 3 and 4

EN ISO 15614-1

Group 9

EN ISO 15614-2

Groups 21 and 22.1

Stud

S 235

4.8 (weld suitable)

16 Mo 3

a b b

2)

–

X 10 CrAl 18

X 10 CrAl 24

X 10 CrNiSi 25-4

c c c –

1.4301, 1.4303

1.4401, 1.4451

1.4571

b (a)

1)

b a –

EN AW-AlMg 3

EN AW AlMg 5

– – – b

Group 1: Steels with minimum yield stress of R

eH

≤ 360 N/mm

2

Group 2: Standardized or thermodynamically treated fine-grain structural steels

with a minimum yield stress of R

e

> 500 N/mm

2

Group 3: Annealed fine-grain structural steels with a minimum yield stress of

R

e

> 500 N/mm

2

Group 4: Steels with Cr max. 0.75%, Mo max. 0.6%, V max. 0.3%

Group 9: Austenitic stainless steels

Group 21: Pure aluminium with max. 1.5% impurities

Group 22.1: Non-curable AlMg alloys with ≤3.5% Mg content

For material combinations that are not listed in the table, a Tucker expert must be

consulted.

*)

EN ISO 15614-1, 2: Specification and qualification of welding procedures for metallic materials – Welding

procedure test

Loading...

Loading...