7 Start-up and weld quality check Page 45

Stud welding unit operating manual Date: July 2021

ALPHA 850 07.2021 / EN Rev.: A

7.5.2 Visual inspection “short cycle drawn arc process”

In this operating manual, the weld joint check is limited to visual inspection of the

welds. A description of the mechanical and technological tests would go beyond the

scope of this operating manual.

Detailed information on this can be found in EN ISO 15614-1, 2*)

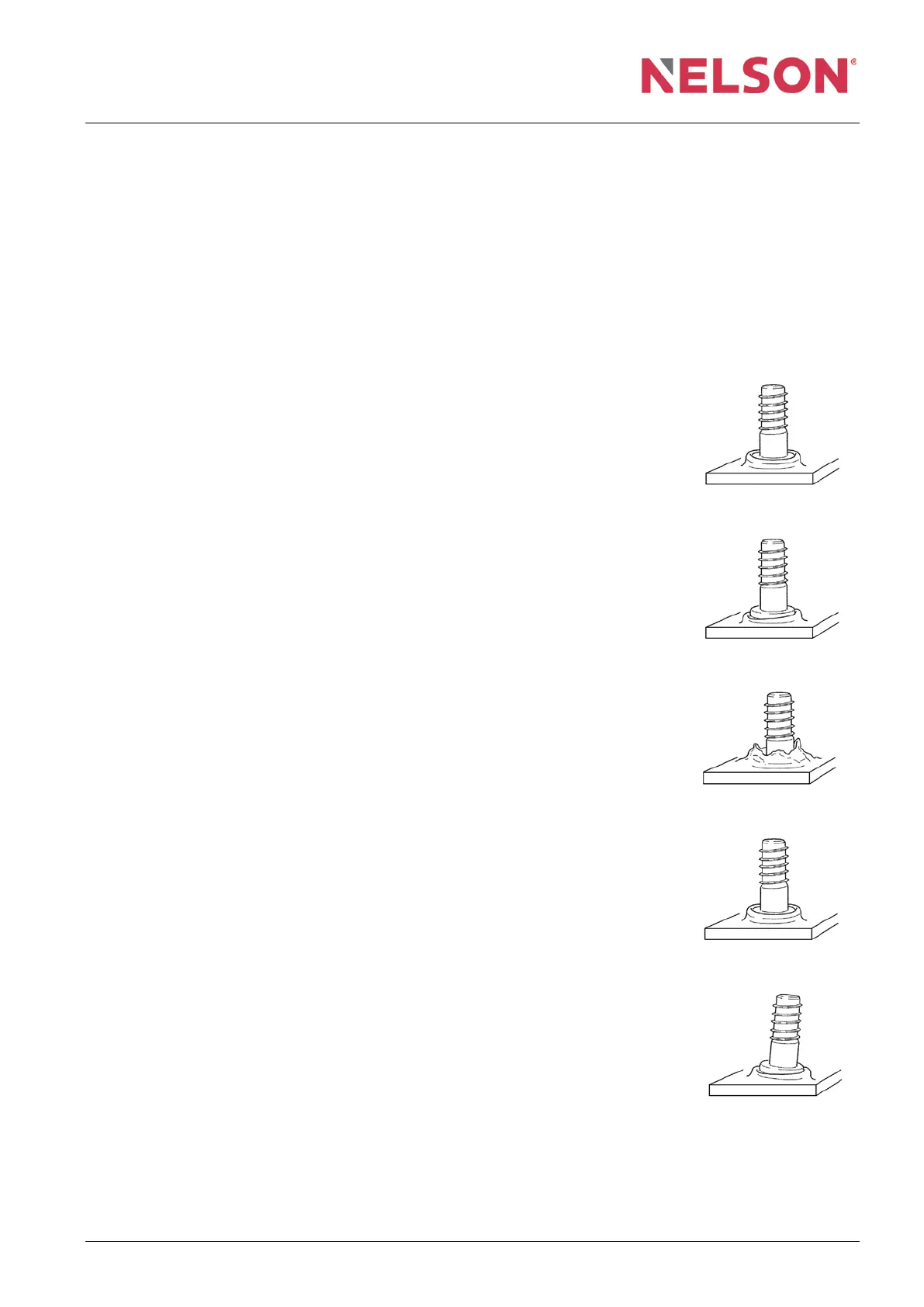

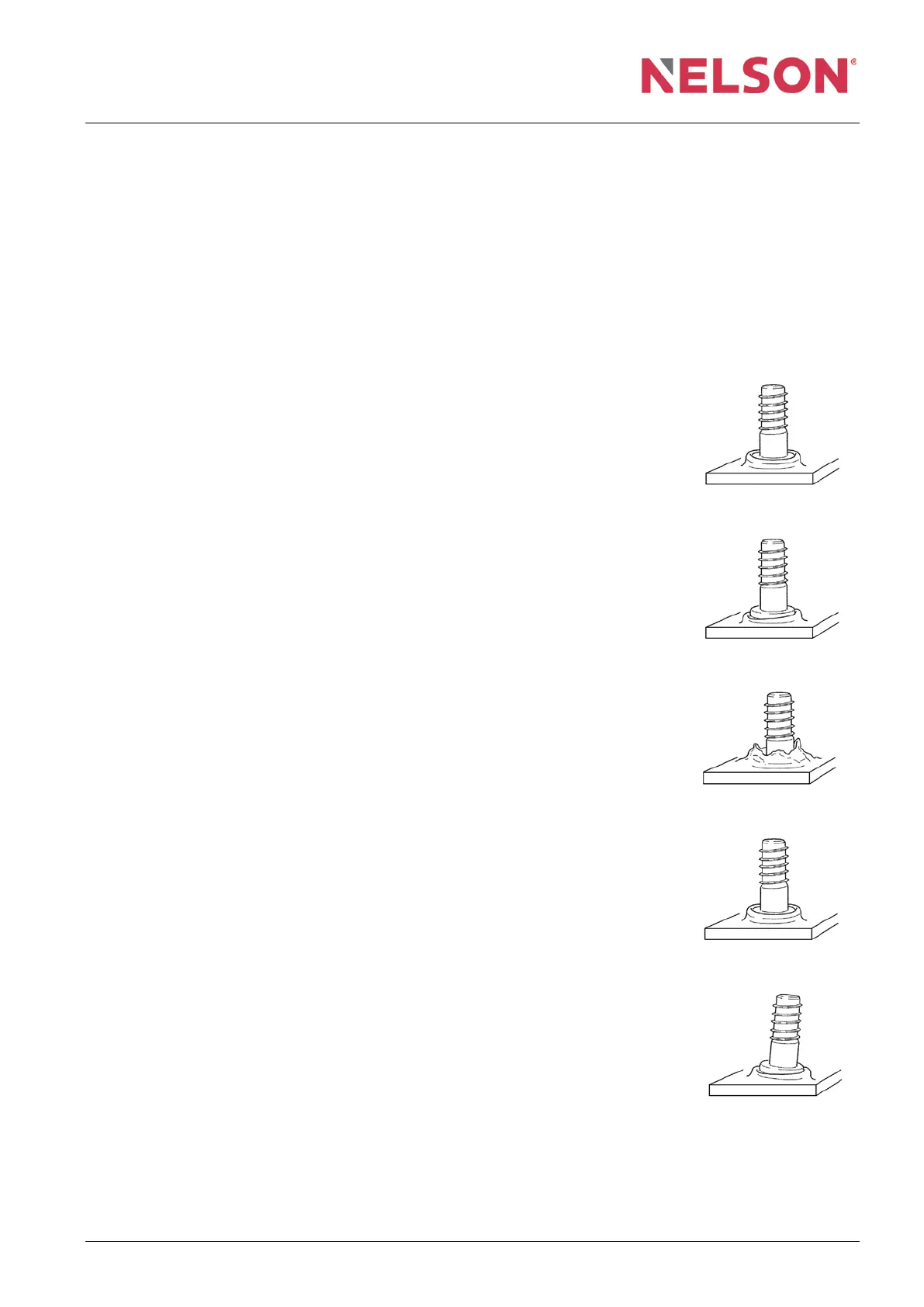

1. Defect-free weld

Weld bead is even, no visible flaws.

Corrective action: Not necessary. No change to the

electrical and mechanical parameters.

2. Defective weld

Diameter not fully welded.

Corrective action: Increase welding current and/or welding

time, possibly change polarity.

3. Defective weld

Large, uneven weld bead.

Corrective action: Reduce weld time.

4. Defective weld

Pores in the weld bead.

Corrective action: Reduce weld time or increase weld

current, weld under shielding gas.

5. Defective weld

Weld bead one-sided.

Corrective action: Eliminate blow effect by applying

smoothing compound or correcting the earth clamps.

*) EN ISO 15614-1, 2: Specification and qualification of welding procedures for metallic

materials – Welding procedure test

Loading...

Loading...