Nelweld Operations and Service Manual

- 14 -

If no gap exists, the current will not create

sufficient heat to melt the metal. Short lift

may allow molten metal to bridge the arc-gap,

resulting in cold welds. Excessively long lift

increases the chance of having arc blow and

welds that are bonded on only one side of the

fillet. Lift is set on the stud gun and is

measured physically when the weld cycle is

initiated. Note that this should be set and

measured by placing the stud and ferrule on a

non-conductive surface and initiating the weld

cycle so that an actual molten weld is not

made while lift is being measured.

• Time is the normal duration of the weld. On

thin base material, shorter than normal time

and higher amperage can be used to achieve

sufficient heat, and still prevent melting

through the base material.

On some base materials, longer times and

reduced amperage improves the ductility of

the weld zone.

• Amperage is the current from the power

source that flows through the weld arc.

Increasing the amperage increases the weld

heat. As with the time setting, a higher

amperage setting is needed for larger stud

sizes. Amperage is set on the stud welding

control system current setting indicator.

• Alignment is centering the stud in the ceramic

ferrule so that the stud does not contact the

ceramic ferrule during the lift and plunge,

which may cause friction or binding between

the stud and ferrule. Binding can slow the

stud plunge so that there is less than full

penetration of the stud into the molten weld

pool resulting in less than full weld strength.

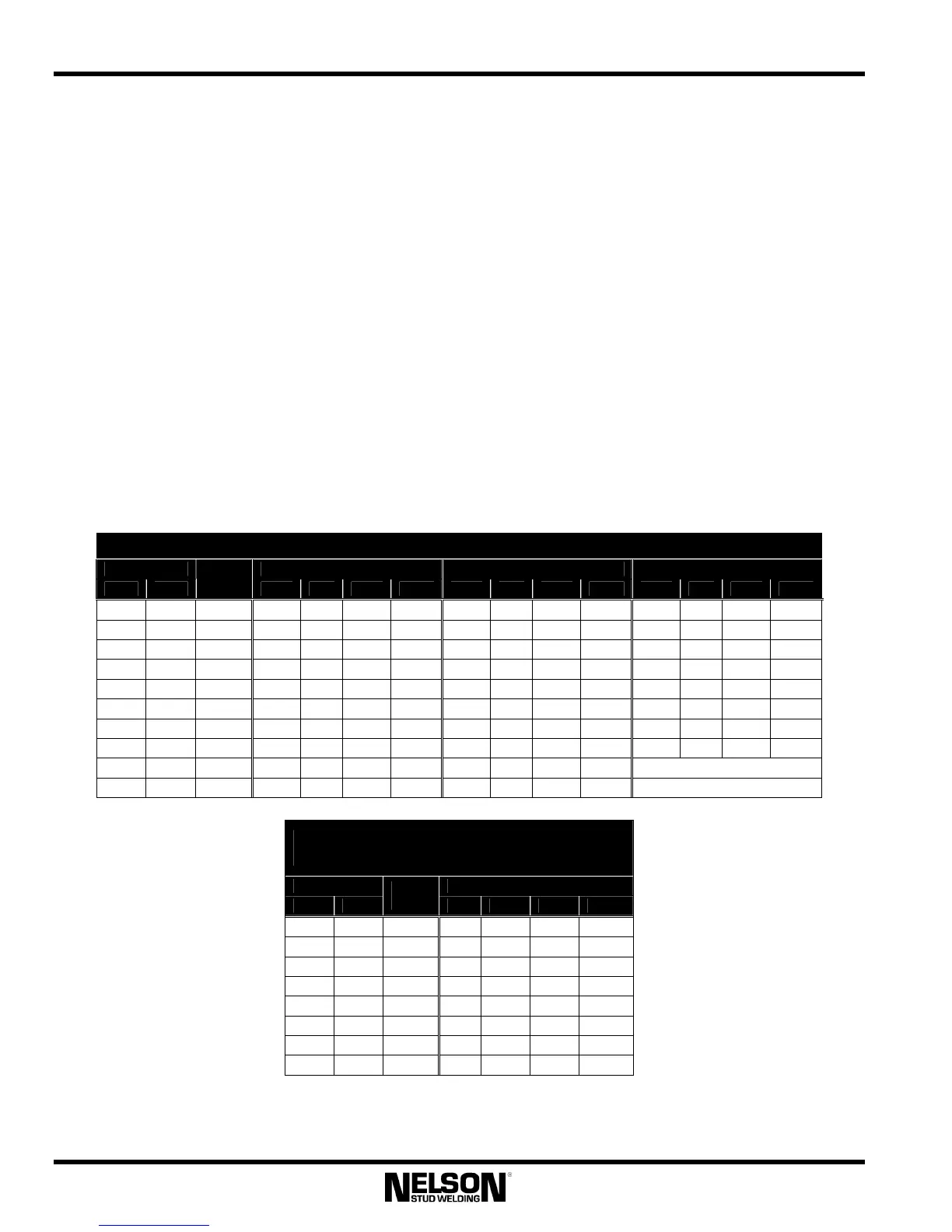

Electric Arc Stud Welding Setups for Mild and Stainless Steel Studs Welded and Base Materials

Diameter Downhand Welding Overhead Welding Vertical Welding

(in) (mm)

Area

(in

2

)

Amp Sec Lift Plunge Amp Sec Lift Plunge Amp Sec Lift Plunge

3/16 4.8 0.0276 300 0.15 0.062 0.093 300 0.15 0.062 0.125 300 0.15 0.062 0.125

1/4 6.4 0.0491 450 0.20 0.062 0.093 450 0.17 0.062 0.125 450 0.17 0.062 0.125

5/16 7.9 0.0767 550 0.25 0.062 0.125 500 0.25 0.062 0.125 500 0.25 0.062 0.125

3/8 9.5 0.1105 650 0.35 0.062 0.125 550 0.33 0.062 0.125 600 0.33 0.062 0.125

7/16 11.1 0.1503 700 0.45 0.062 0.125 675 0.42 0.062 0.125 750 0.33 0.062 0.125

1/2 12.7 0.1964 850 0.55 0.062 0.125 800 0.55 0.062 0.125 875 0.47 0.062 0.125

5/8 15.9 0.3068 1200 0.70 0.062 0.187 1200 0.67 0.093 0.187 1275 0.60 0.062 0.187

3/4 19.1 0.4418 1500 0.90 0.093 0.187 1500 0.84 0.093 0.187 1700 0.73 0.093 0.187

7/8 22.2 0.6013 1750 1.10 0.125 0.250 1700 1.00 0.125 0.250 Not Recommended

1 25.4 0.7854 2000 1.40 0.125 0.250 2050 1.40 0.125 0.250 Not Recommended

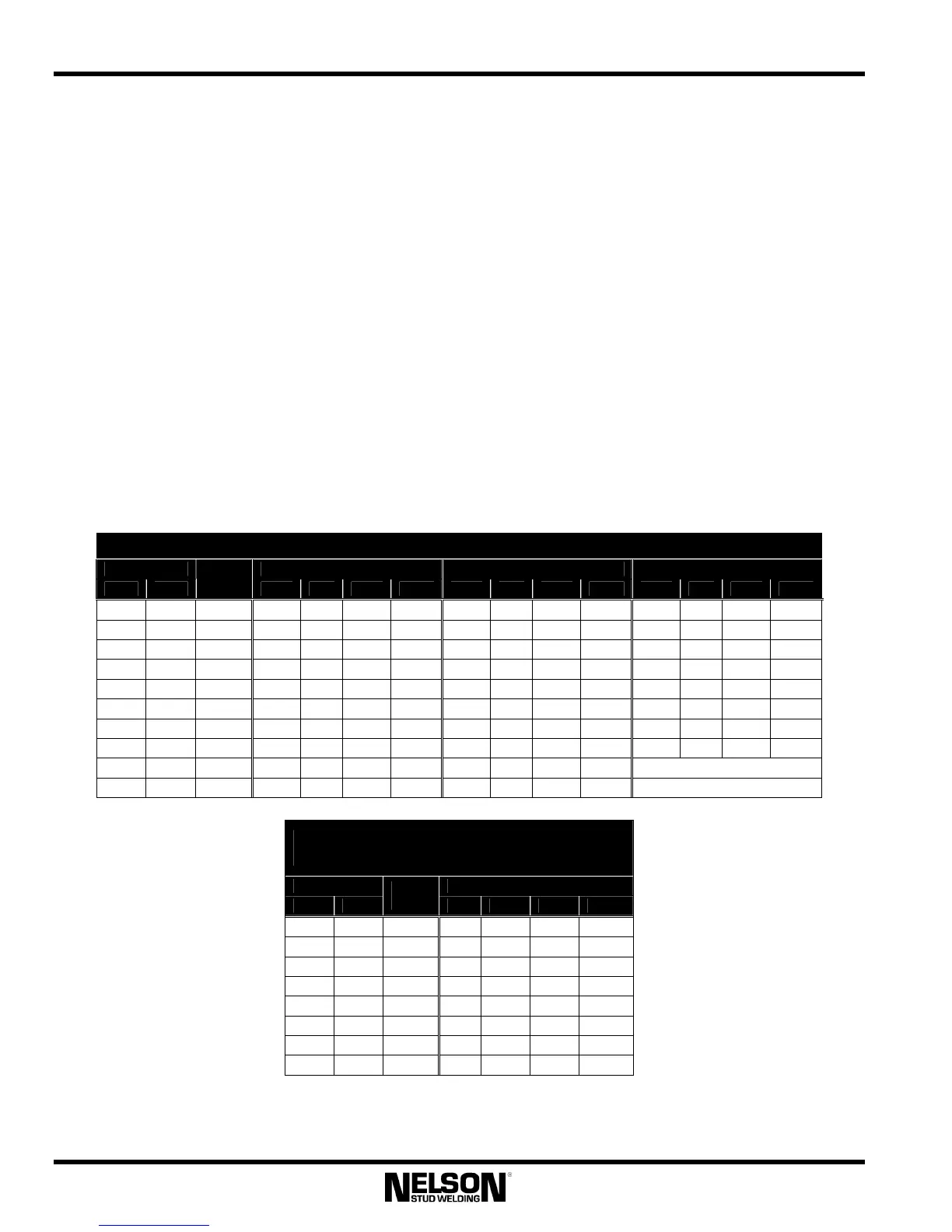

Short Cycle Welding Setups for Mild and

Stainless Steel Studs and Base Materials

Diameter All welding positions

in mm

Area

(in

2

)

Amp Sec Lift Plunge

0.156 4 0.019 400 0.060 0.040 0.062

0.198 5 0.031 500 0.070 0.050 0.062

0.237 6 0.044 600 0.080 0.050 0.062

0.276 7 0.060 650 0.090 0.062 0.062

0.315 8 0.078 700 0.100 0.062 0.080

0.354 9 0.098 800 0.120 0.062 0.100

0.394 10 0.122 900 0.150 0.070 0.100

0.471 12 0.174 1100 0.180 0.080 0.120

Loading...

Loading...