Nelweld Operations and Service Manual

- 47 -

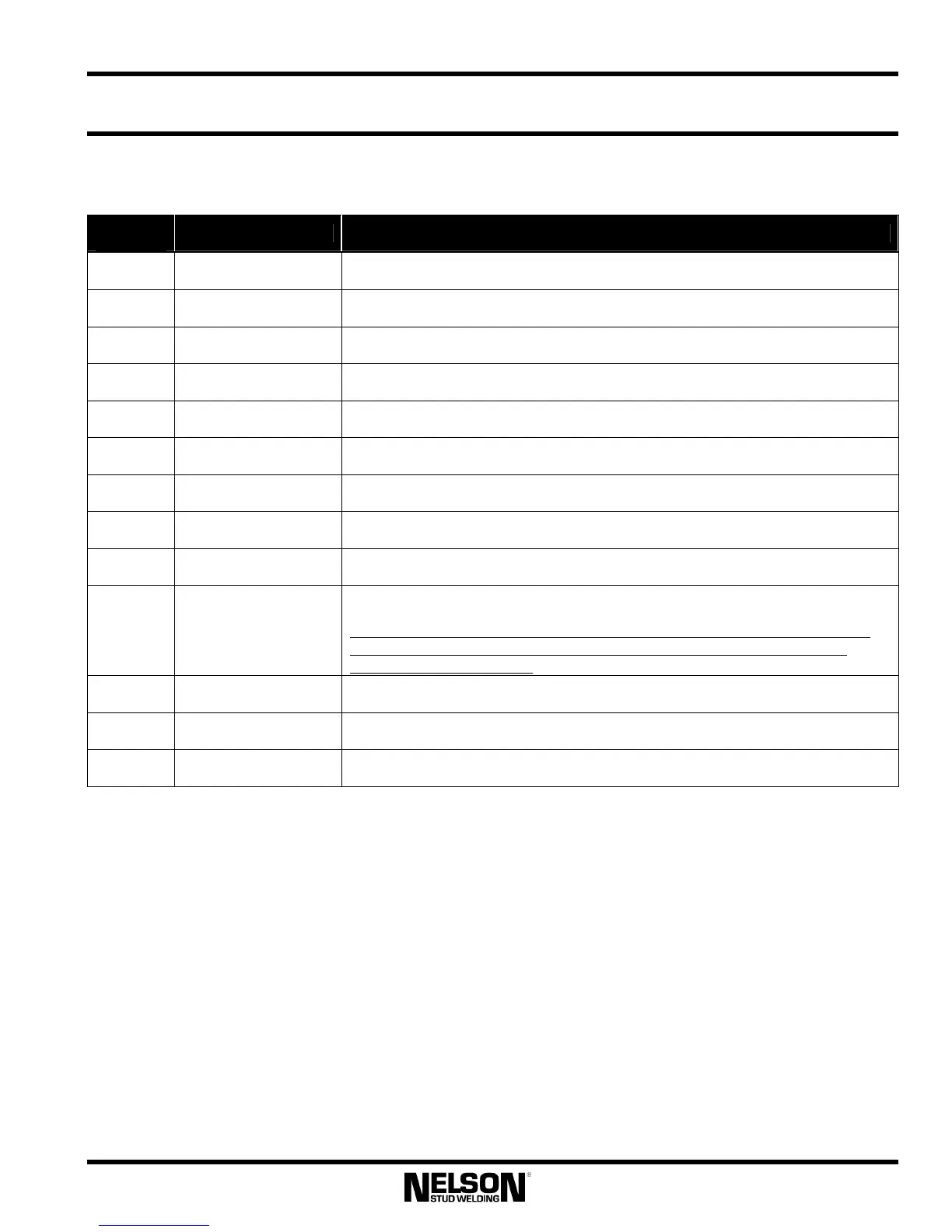

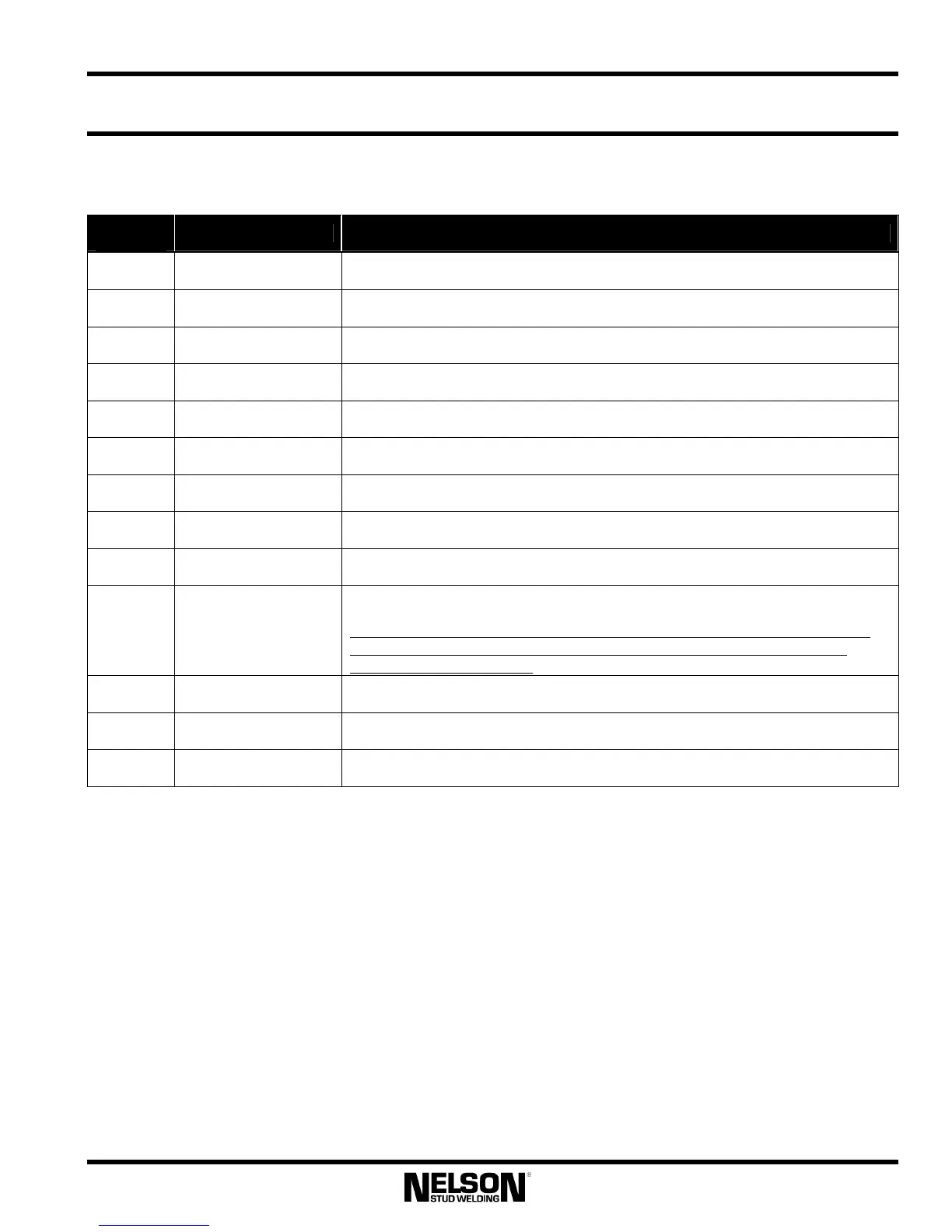

6.2 Diagnostic codes – Troubleshooting Guide

The diagnostic codes can be accessed via the F1 Special Function Mode. The E codes can be scrolled with

the up/down keys next to the LED Display. The error codes are erased when the unit is shut off.

Diagnostic

Code

Description Recommended Action

E001 Line Frequency Error Invalid frequency detected. Ensure the proper line frequency is being used.

E002 Missing Phase

Phase B or C (with respect to Phase A) was not detected. Ensure that all input power

phases are present.

E005 EEPROM Failure Main Control PCB failure.

E006

Dual Output

Communications Error

Check harness connections between control PCB’s.

E007

Gun Coil or Gun Cable

Shorted to Work

Check gun coil wiring, or gun control cable for broken insulation or water immersion

of a gun control connector.

E008 Gun Coil Open Check gun coil wiring and related circuit wiring

E009 Gun Lift Error A short was detected after the pilot arc time expired – Check gun.

E010 Shunt Signal Open No pilot arc current detected and/or the arc current went out. Check shunt wiring.

E012 Time Control Fault Main weld arc went out. Clean surface or change weld parameters.

E015

High Temperature

Fault

Welding is disabled until the unit’s welding power supply cools to an acceptable level.

This code will display automatically with or without F1 diagnostic mode enabled.

This error will occur if the pilot arc board is unable to supply 15VDC. The 15VDC

supply exists if two green LEDs on the pilot arc board are lit. If they are not lit,

replace the pilot arc board(s).

E016 SCR Shorted Check shunt wiring. Replace defective SCR.

E017 Weld Quality Error

Weld was outside of specified tolerance. Only valid for Process Monitor users. See

the Nelware users manual for details.

E018 Security Error An incorrect security code was passed to the Nelweld through the RS-232 port.

Loading...

Loading...