7 MAINTENANCE

PAGE

7.3R

Recommended for the following applications:

- Low temperature (danger of freezing)

- Operation in a vacuum (dry running)

- Media which must be isolated from the atmosphere (eg. due to build up of solid

deposits or because of less severe damage to the environment, like smell)

Leakages will be transportet away by the quenching liquid.

In vacuum operation dry running of the seals is avoided.

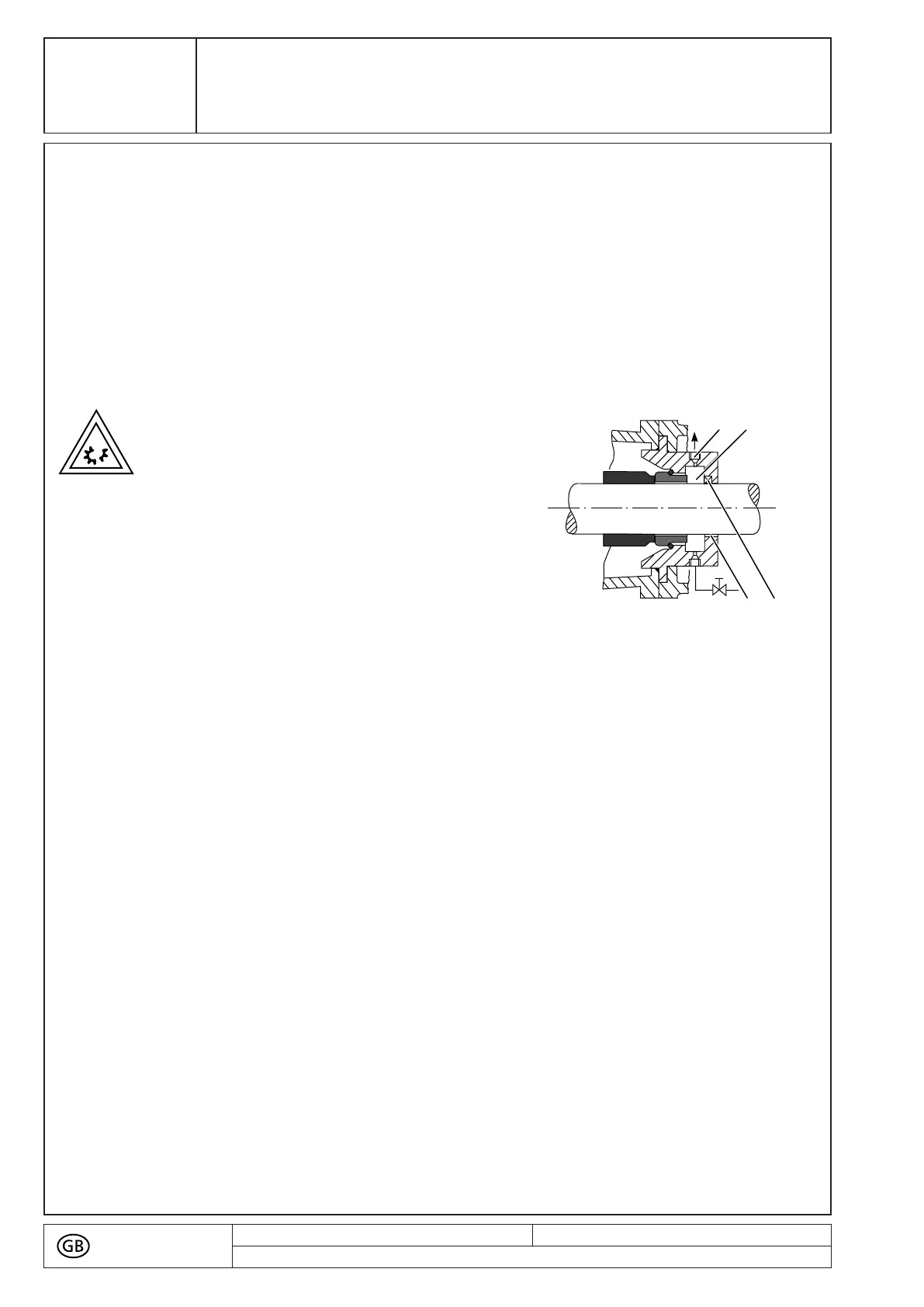

No pressure higher than that of the pumped

medium in front of the mechanical seal is allowed

to build up in the quenching area (1) behind the

mechanical seal. Otherwise the counter ring will be

pushed out of the housing. Free discharge from (2)

is necessary!

Closing off the quenching area from the

atmosphere can be done in three ways:

1. In the case that high emission levels can be

tolerated:

Through a throttle bush (4). Cooling liquid not

permanently used, only released from time to time.

2. In the case that medium emission levels can be tolerated:

By a radial shaft seal ring (3). Permanent radial shaft seal lubrication through

quenching liquid is necessary.

3. In the case that low emission levels can be tolerated:

By installing an additional single mechanical seal. This results in forming a double

mechanical seal in tandem arrangement. Permanent mechanical seal lubrication on

the atmospheric side through quenching liquid is necessary.

For procedures 2 and 3 requiring permanent quench, the supply of quenching liquid

can be performed in two ways:

1. Feeding in via a supply line over a throttle / check valve, and having an outlet from

the seal quench area.

2. Feeding in through a tank, which should be arranged maximum one meter above

the seal, and having a drain valve from the seal quench area. The level mark in the

tank must always show and the filling be half way on the sight glass. Control

intervals should be determined by the user.

The quenching liquid should be changed and the quenching area should be cleaned

periodically.

Background: there is an exchange of media between quenching liquid and the

pumped media. If you have a sticky pumped media the rising concentration of this

media within the quenching liquid might cause the mechanical seal to stick together.

By the time impurities of the media might settle in the quenching area.

text no.

R 07400-1/2

issued: 09.01.2013 Revision: 6

copy to:

IPP - EN - EN_07400_20130109/2 - D8411276 - 4300003998 - 000100 - NPS - 00229929 N 2018-02-21 19:03:25

Loading...

Loading...