Outside combustion air may be required if:

1. the solid-fuel-fired appliance does not draw steadily, experiences smoke roll-out, burns poorly, or back-drafts whether or

not there is combustion present;

2. existing fuel-fired equipment in the house, such as fireplaces or other heating appliances, smell, do not operate properly,

suffer smoke roll-out when operated, or back-draft whether or not there is combustion present;

3. any of the above symptoms are alleviated by opening a window slightly on a calm (windless) day;

4. the house is equipped with a well-sealed vapor barrier and tight lifting windows and/or has any powered devices which

exhaust house air;

5. there is excessive condensation on windows in the winter; or

6. a ventilation system is installed in the house.

If these or other indications that infiltration air is inadequate, additional combustion air should be provided from the outdoors.

BELT TENSION: When adjusting the proper pulley setting make certain that the belt is able to flex at least one inch without

movement of the motor pulley.

DUCT INSTALLATION: To prevent excessive noise and temperature rise, limit the minimum return air duct size to at least 250

square inches (in

2

). Because the unit may be used as a gravity furnace when the power is off, the following is recommended:

1. Locate the furnace as centrally as possible in the home so the best warm air distribution may be enjoyed.

2. Use an extended plenum (central duct) at least one size larger than called for in National Warm Air Standards.

3. Use a minimum pipe size of six inches in diameter in runs and in no case smaller than five inch diameter.

4. Slope extended plenums and runs as much as possible to facilitate gravity flow of warm air.

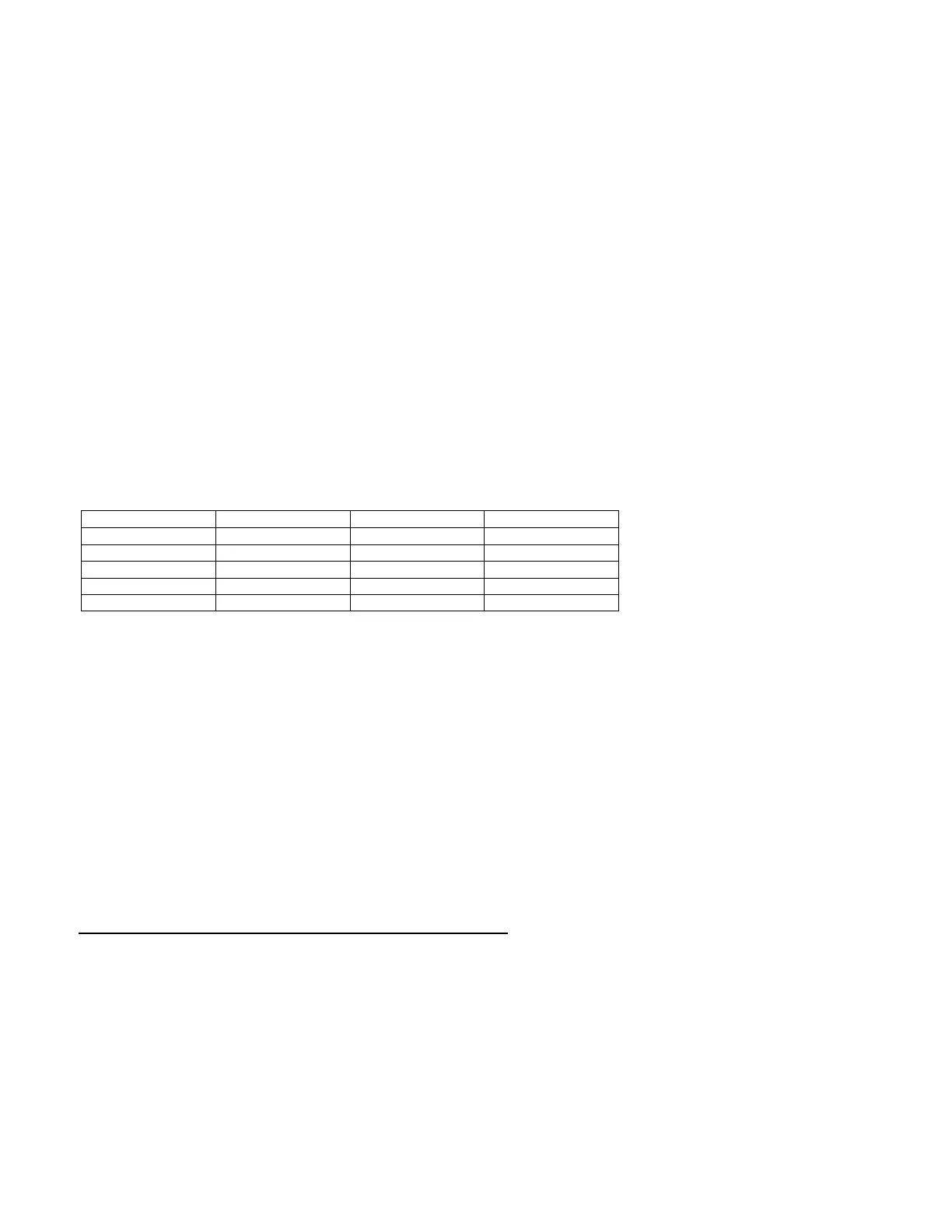

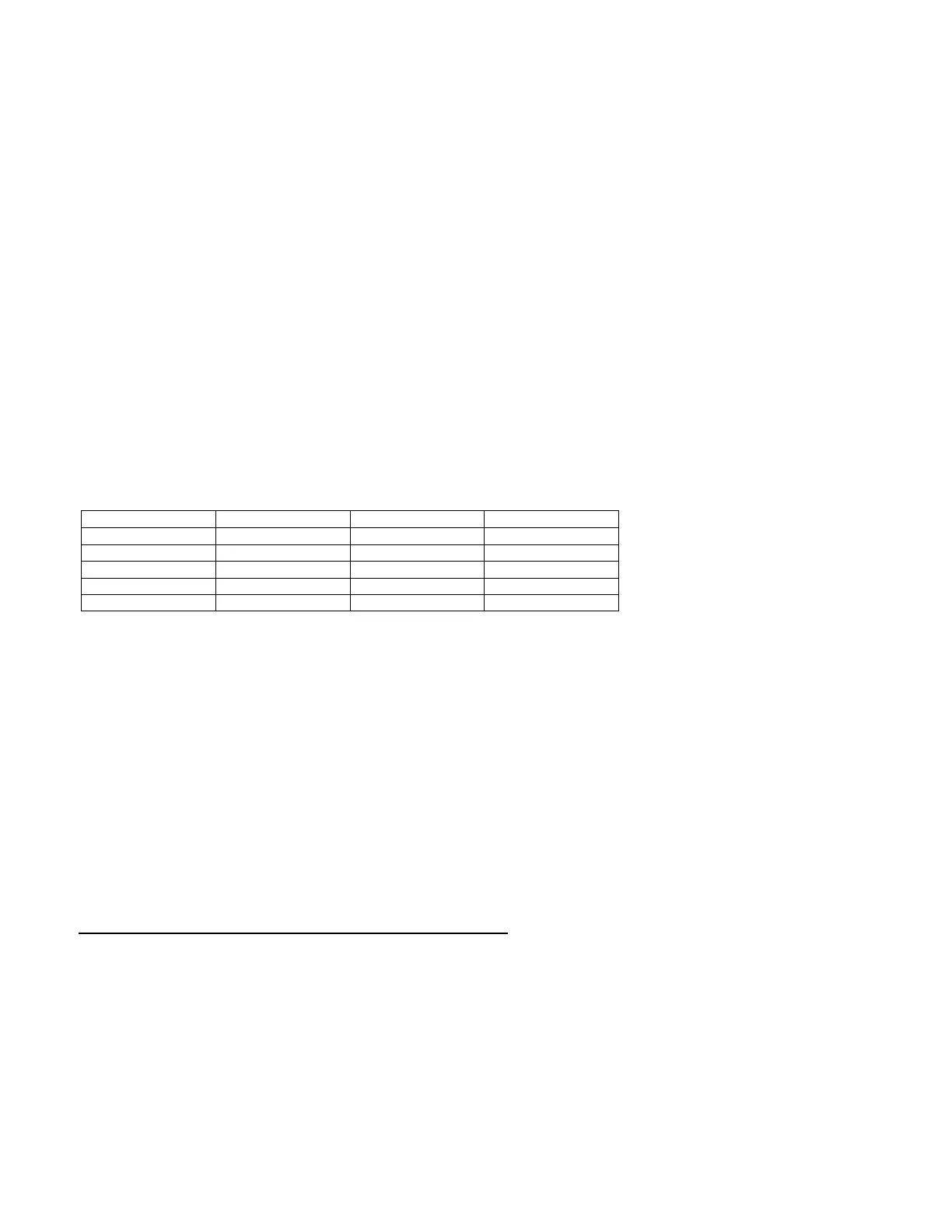

IMPORTANT: FIG. 4 - MINIMUM DUCT SIZES

The above chart gives the MINIMUM free area duct size. The supply air extended plenum should be 8 – 10 feet out from the

furnace with the sizes shown in the chart, then gradually transitioned to the end of duct system. If the plenum is lower than 24

inches high, increase the duct size proportionately. The Supply Air free area for CL-115 C&G is the same as CL-140 C&G

because the wood burning portion of the furnace can produce 140,000 BTU.

HUMIDIFIER: Install humidifier in the return air plenum. This prevents possible damage due to excessive temperatures when

there is a power failure.

Metal connecting ducting from the warm air plenum should be used.

OIL FIRED BLOCKED VENT SWITCH - MODEL WMO-1

Refer to the Newmac and Field Controls Instructions enclosed in the WMO-1 package.

Do not use the WMO-1 Blocked Vent Switch with the Newmac SVS Sealed Vent System

When installed on the chimney vent or on the appliance burner plate according to these instructions, the manually reset WMO-

1 blocked vent switch is designed to shut off power to the oil burner if the hot flue gases in the chimney vent connector pipe

back up sufficiently to activate it. The WMO-1 switch is required on new Newmac oil-fired and combination furnaces or boilers

installed in Canada. It must be installed by a qualified installer in accordance with the manufacturer's installation instructions.

Electrical wiring must be in accordance with applicable codes and the Canadian Electrical Code. Before leaving the appliance

check that the WMO-1 switch and its cover are tightly secured.

Installation on the Burner Plate - combinations - Figs. 5A and 5B

1. See Fig. 5A. Remove the 5/8" diameter plug in the burner plate. Cut or file a hole in the rigid fibreglass insulation, behind

the 5/8" hole in the burner plate, large enough that the WMO-1 securing nut will seat against the back of the burner plate.

Remove one of the securing nuts from the tube of the WMO-1 assembly. Tighten the remaining nut onto the tube as far as

possible.

2. See Fig 5B. With the WMO-1 assembly outside the burner plate, insert the threaded tube end into the 5/8" diameter hole

in the burner plate, re-install the first securing nut onto the tube on the inside of the burner plate. Tighten securely.

CAUTION: Disconnect the electrical power supply before wiring the WMO-1 assembly.

3. See Fig. 5C. Using suitable AC90 flexible (BX) conduit or equivalent, wire the WMO-1 switch in series with the appliance

limit circuit. Connect at the burner junction box.

4. Check the operation of the WMO-1 switch before leaving the appliance. The WMO-1 switch is reset by pushing the square

red button.

WMO-1 Blocked Vent Switch Check

Loading...

Loading...