7.2 - Diagnostics

Some devices are supposed to issue warnings that allow identifying their status or any faults.

Table 6 describes the various messages with their relative causes and solutions; the warnings are based on combinations of colours, OK led ashing and a

possible, suitably programmed, asher connected to the outputs of the control unit.

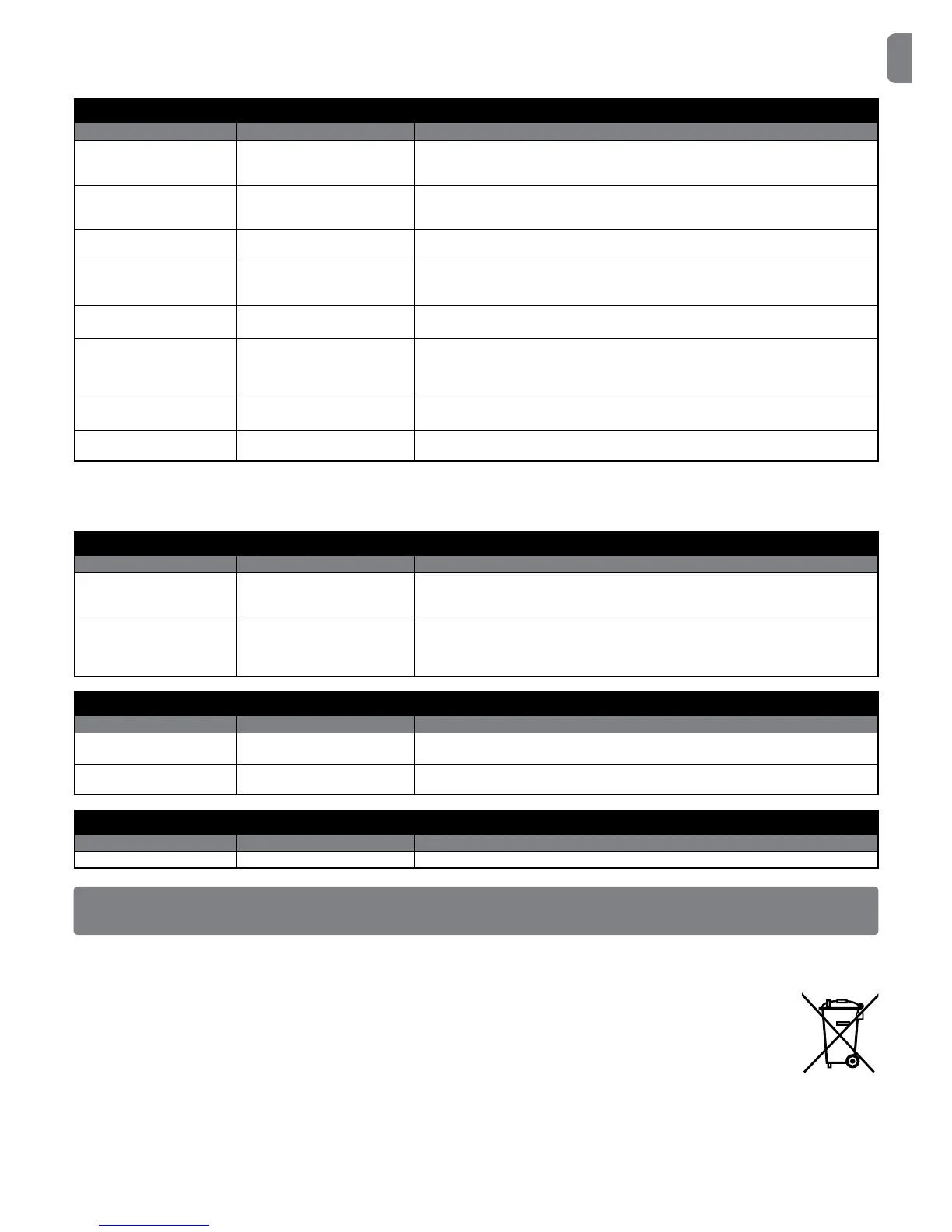

TABLE 6: OK LED SIGNALS (ashing red)

Signal Cause Solution

2 ashes - 1 sec. pause

2 ashes - red led

Triggering of a photocell At the beginning of the manoeuvre, one or more photocells are preventing movement;

check if there are any obstacles.

During the closing movement it is normal if an obstacle is present.

3 ashes - 1 sec. pause

3 ashes - red led

Intervention of the “Driving

Force” or “Sensitivity” or

“Blocked Encode” limiter

While moving, the door has met with increased friction: check its cause.

4 ashes - 1 sec. pause

4 ashes - red led

Activation of the STOP input At the start of the manoeuvre or during the movement, the STOP ALT input has been trig-

gered or the motor release lever has been activated: check the cause.

5 ashes - 1 sec. pause

5 ashes - red led

Internal parameter memorisation

error

Press the STOP button on the box lid to reset the error.

Wait for at least 30 seconds to allow the control unit to reset. If the situation does not

change, it is necessary to delete the memory and carry out the storing procedure again.

6 ashes - 1 sec. pause

6 ashes - red led

Maximum limit of manoeuvres

per hour exceeded

Wait for a few minutes to allow the manoeuvre limiter to go back below the maximum.

7 ashes - 1 sec. pause

7 ashes - red led

Error in the internal electrical

circuits

Press the STOP button on the box lid to reset the error.

Disconnect all the supply circuits for a few seconds, then try and send a command again;

if the situation does not change there may be a serious fault on the board or on the motor

wiring: check and replace as required.

8 ashes - 1 sec. pause

8 ashes - red led

Command already present Another command is already present.

Remove the command to be able to send more.

9 ashes - 1 sec. pause

9 ashes - red led

Automation blocked Send an automation unlocking command to reset normal operation.

Note – The diagnostic signals provided by ashing LEDs stop when the control unit is given a command.

By using an external ashing light*, the diagnostics signals continue for two sequences of ashes (e.g. “3 ashes – short pause – 3 ashes – long

pause” repeated twice).

* Congured with the Oview programmer as “Flashing Light 1”

TABLE 7: OK LED SIGNALS (red light ON - green ashing)

Signal Cause Solution

Red light on

8 ashes - 1 sec. pause

8 ashes - green led

Encoder error.

No signal

Press the STOP button on the box lid to reset the error.

Check if the encoder cable has detached.

Red light on

10 ashes - 1 sec. pause

10 ashes - green led

Manoeuvre timeout.

The duration of the manoeuvre

has exceeded the one stored

during the learning phases

Press the STOP button on the box lid to reset the error.

If necessary, repeat learning the positions or change the value of the manoeuvre Time,

using the Oview programmer.

TABLE 8: OK LED SIGNALS (ashing red and green)

Signal Cause Solution

Alternate red - green ashing Dip switch conguration modied Check the conguration and, if correct, conrm keeping the P1 button pressed for 2 sec-

onds

Red a nd green alternate

ashing during the manoeuvre

Force learning in progress Carry our 4 complete manoeuvres to perform the learning of the forces required for handling.

Caution: during this phase the control unit uses maximum force.

TABLE 9: OK LED SIGNALS (ashing orange)

Signal Cause Solution

Fast orange ashing Dip switch 2-B on ON Modify the speed with the “OPEN” / “CLOSE” keys and set dip switch 2-B to OFF

8

DISPOSAL OF THE PRODUCT

This product is an integral part of the automation system, therefore it must be disposed of along with it.

As in installation, also at the end of product lifetime, the disassembly and scrapping operations must be performed by qualied personnel.

This product is made up of different types of material, some of which can be recycled while others must be disposed of. Seek information on

the recycling and disposal systems envisaged by the local regulations in your area for this product category.

Caution! – Some parts of the product may contain pollutants or hazardous substances which, if released into the environment, may cause

serious damage to the environment or human health.

As indicated by the symbol on the left, disposal of this product in domestic waste is strictly prohibited. Separate the waste into categories for

disposal, according to the methods envisaged by current legislation in your area, or return the product to the retailer when purchasing a new

version.

Caution! – Local legislation may envisage serious nes in the event of abusive disposal of this product.

Loading...

Loading...