4.3 - Learning about the safety devices and DIP SWITCH pro-

gramming

After switching on for the rst time (paragraph 3.7) and before setting the door

Opening and Closing positions, the control unit must recognize the:

- safety devices connected to the “STOP Safety Edge” input

- photocell connection in standard or phototest mode

- settings of dip switches A and B.

NOTE: when dip switch A or B is modied, the OK led ashes alternatively

green and red to highlight that the device learning phase must be carried out

again.

CAUTION! - During the learning phase, at least one safety device

must be connected to the control unit.

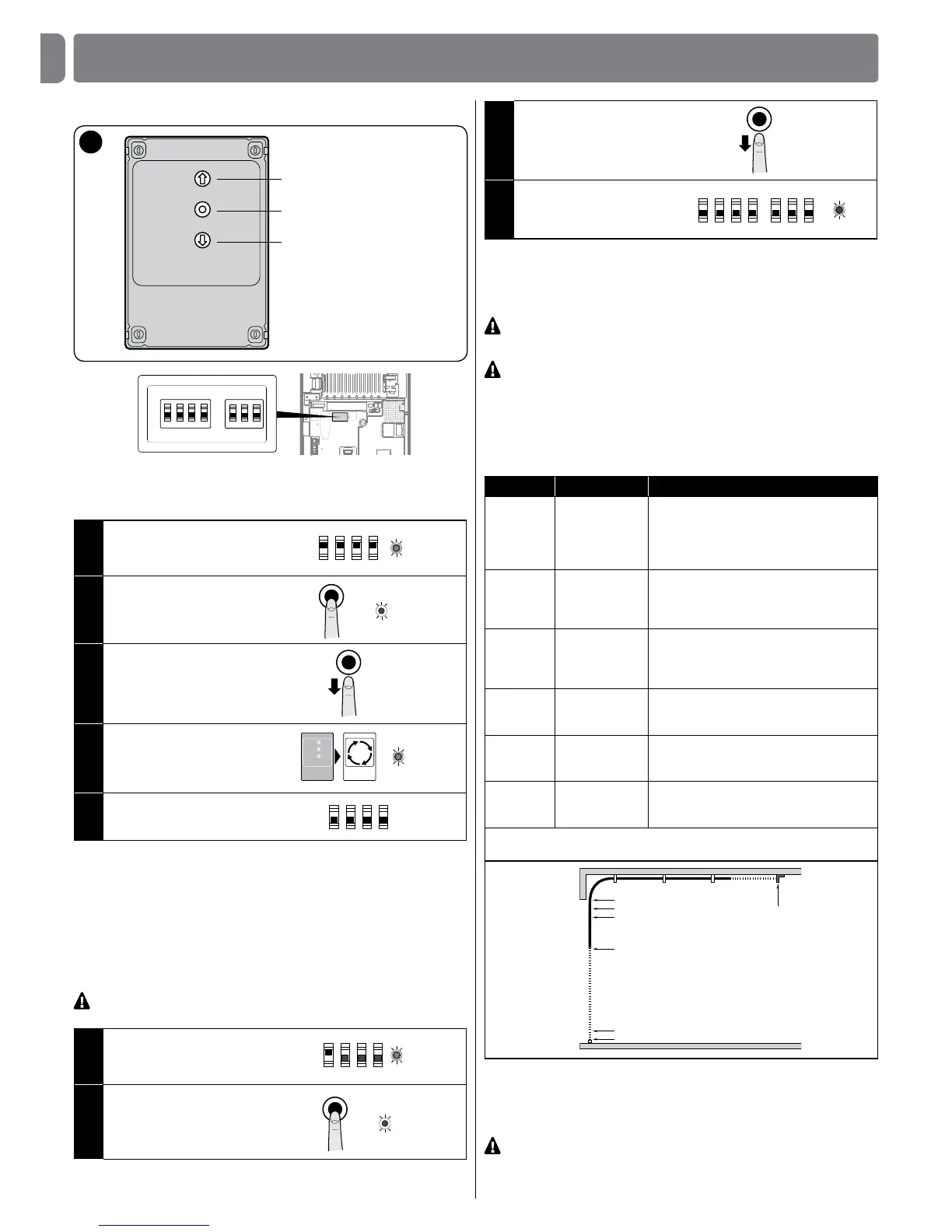

01. Set dip switch A-1 to

ON = the led ashes

quickly with green light

ON

OFF

1 2 3 4

A

02. Keep the STOP button

pressed for 3 seconds

until the led is on with

xed red light (after

about 3 seconds)

3”

4

PROGRAMMING

03. Release the STOP

button

04. Set all dip switches to

OFF = the green led

ashes slowly or as per

previous programming

OFF

1 2 3 4

A

1 2 3

B

This procedure must be repeated when a change to the “STOP Safety Edge”

terminal (e.g. after connecting a device to the control unit) or the phototest

connection or dip switches A or B is made.

After learning about the safety devices in the automation, the control unit must

recognize the door Opening and Closing positions.

CAUTION! - The procedures to learn about the safety devices and the

door Opening and Closing positions must be carried out one after the other

and without interruptions. They cannot be performed at different times.

CAUTION! - Procedure for motors with incremental encoders: after per-

forming the Opening and Closing position learning procedure, the control unit

must perform a self-learning procedure of the forces (5 cycles of complete

manoeuvres, the door stops in the Closing position).

4.4 - Learning the Opening and Closing positions with an

incremental encoder

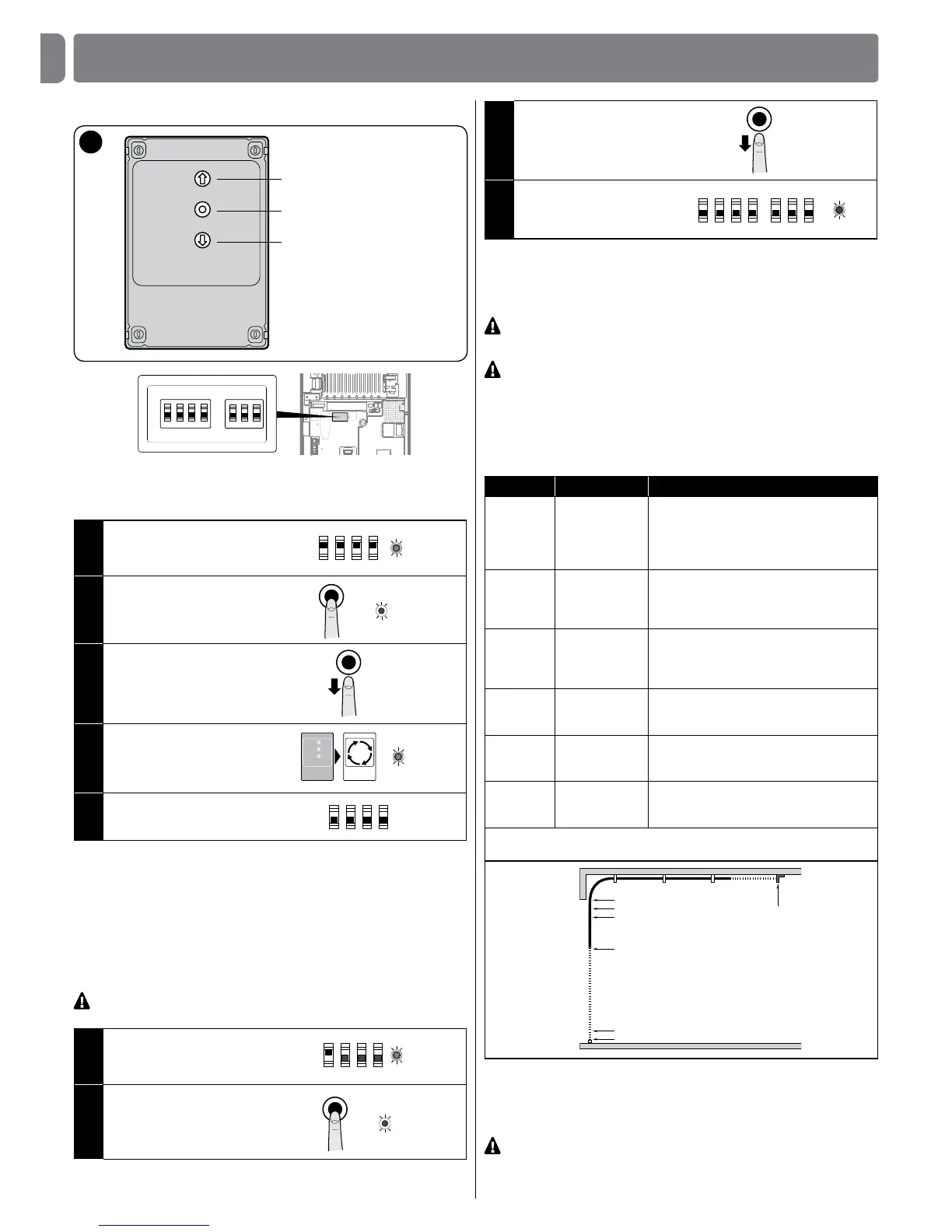

3 positions can be programmed, as described below:

Position Action Meaning

0 Close Maximum closing value. When the door

reaches this position, it stops; this match-

es the mechanical stop (generally the oor).

It can be programmed with the electronic

board or Oview programmer.

1 Opening

stop

Door maximum opening position, correspond-

ing to the opening mechanical stops (M in the

picture below). The opening value must be

smaller than this point.

A Open

Door stop desired position during opening

(does not match the opening mechanical

stops).

It can be programmed with the elec-

tronic board or Oview programmer.

B Partial

opening

Door stop desired position during

partial

opening. It can be programmed with the

electronic board or Oview programmer.

RA Slow down

Open

Door desired position for

slow down start

during opening. It can be programmed only

with the Oview programmer.

RB Slow down

Close

Door desired position for

slow down start

during closing. It can be programmed only

with the Oview programmer.

Note: positions B, RA and RB are calculated automatically by the control

unit; to change them, the Oview programmer must be used (accessory).

1

A

M

RA

B

RC

0

These manoeuvres are carried out at low speed. If the door is in the closing po-

sition, it must be positioned manually at about 50 cm from the ground, using the

emergency system (see the motor instruction manual) in order to prevent, if the

rotation is reversed, the track ropes from coming out of their housing (sectional

doors) or the excessive winding of the shutters (rolling shutters).

Important - Unlocking with Nice SUMO motor: when the SUMO mo-

tor is unlocked, if the DPRO924 control unit is on, it stores the command. To

synchronize the encoder position again, closing as far as the maximum closing

position must be performed. The opening manoeuvre must be carried out in

Loading...

Loading...