10 – ENGLISH

3.7 INSTALLING THE GEARMOTOR

a

Incorrect installation may cause serious physical

injury to the person working on the system or to its

future users.

Before starting to assemble the automation, com-

plete the preliminary checks described in the “Pre-

installation checks” and “Product usage limits”

paragraphs.

If there is a support surface:

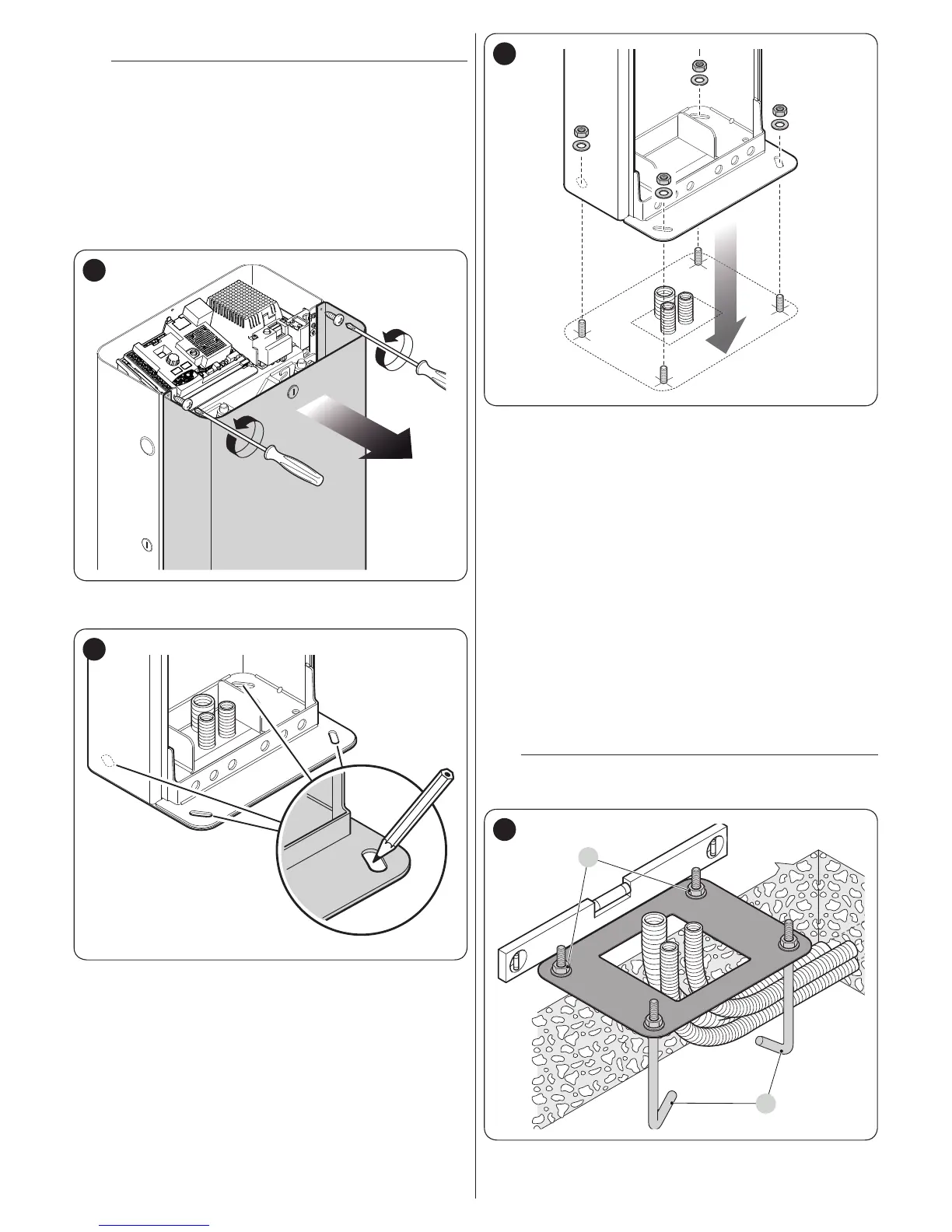

1. open the cubicle panel

15

2. place the cubicle on the anchoring surface and mark the

points corresponding to the slots

16

3. move the cubicle and drill the surface through the marked

points

4. insert 4 expansion bolts (not supplied)

5. arrange the cubicle properly and secure it with the appro-

priate nuts and washers (not supplied).

17

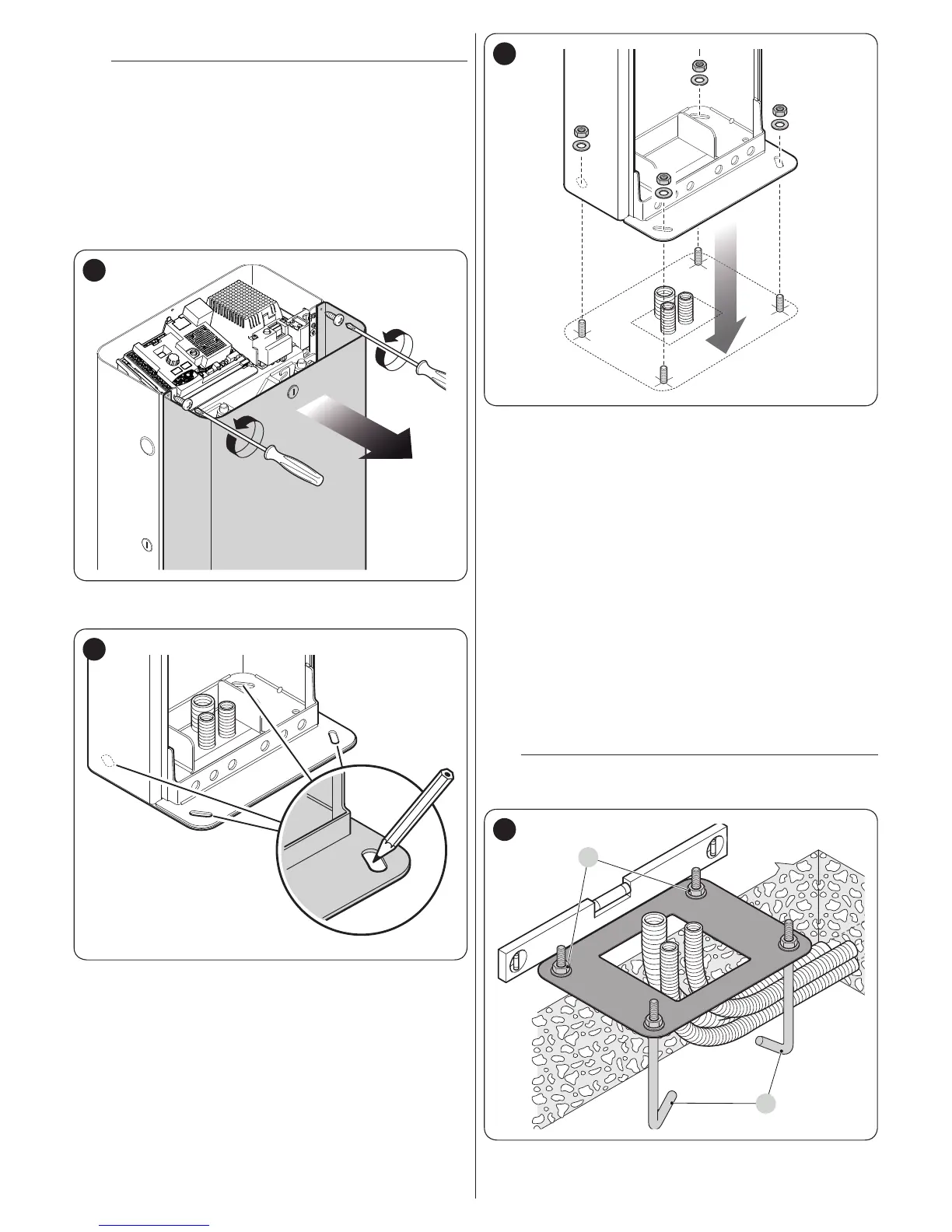

If there is no support surface:

1. dig the hole to insert the foundation plate

Note The anchoring surface must be completely at and

smooth. If the surface is made of concrete, the latter

must be at least 0,15 m thick and must be suitably rein-

forced with iron cages. The concrete must have a vol-

ume above 0.2 m

3

(a 0.25 m thickness corresponds to

0.8 m

2

, that is, equal to a square base with sides each

measuring roughly 0.9 m). The plate can be anchored to

the concrete using the 4 expansion bolts, equipped with

12 MA screws capable of withstanding a tensile load of

at least 400 kg. If the anchoring surface is made of a

different material, it is necessary to verify its consistency

and whether the four anchoring points can withstand a

load of at least 1,000 kg. Use the 12 MA screws to fas-

ten the plate.

2. arrange the pipes for routing the electrical cables

3. fasten the four anchor bolts (A) to the foundation plate, in-

serting a nut and washer (supplied) on each, on the upper

and lower sides of the plate

m

The lower nut must be screwed up to the end of the

thread.

A

B

18

Loading...

Loading...