English – 11

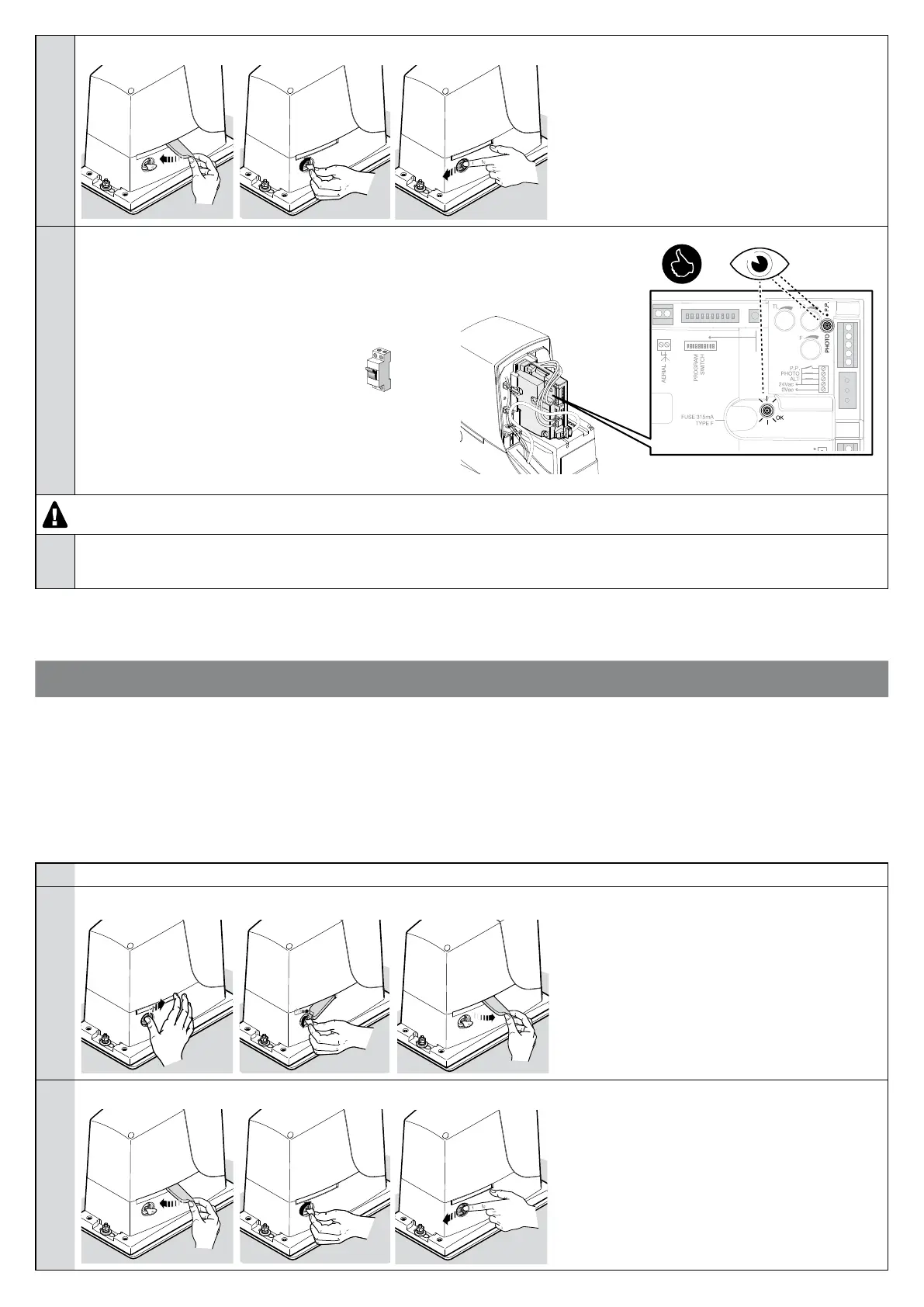

03. Manually lock the gearmotor

04. Power the automation up and check:

- that the OK led is ashing regularly: 1 ash

per second

- that the gate does not move and that the

asher is off

ON

if any of these conditions are not satised, proceed as follows (step 05)

05. Shut off mains power to the automation and check the electrical connections, photocell alignment, and fuses. If necessary, check the

limit switch connections: move the limit switch levers and check that the switch trips and turns off the FCA / FCC led on the control

unit respectively

6

TESTING AND COMMISSIONING

These are the most important phases of automation set-up to ensure maximum system safety.

They must be done by a qualied technician who agrees to run the tests and check the solutions to any risks present, as well as checking com-

pliance with regulations, standards and the law: in particular, the requirements of EN 13241-1, EN 12445 and EN 12453.

Any supplementary equipment must be tested separately for operation and interaction with the ROX: refer to the respective user manuals.

6.1 - Testing

The testing procedure can also be performed as a periodic check of the automation devices. Each component of the system (sensitive edges,

photocells, emergency stop, etc.) requires a specic testing phase. To do so, follow the procedures given in the instruction manuals.

Run the test as follows:

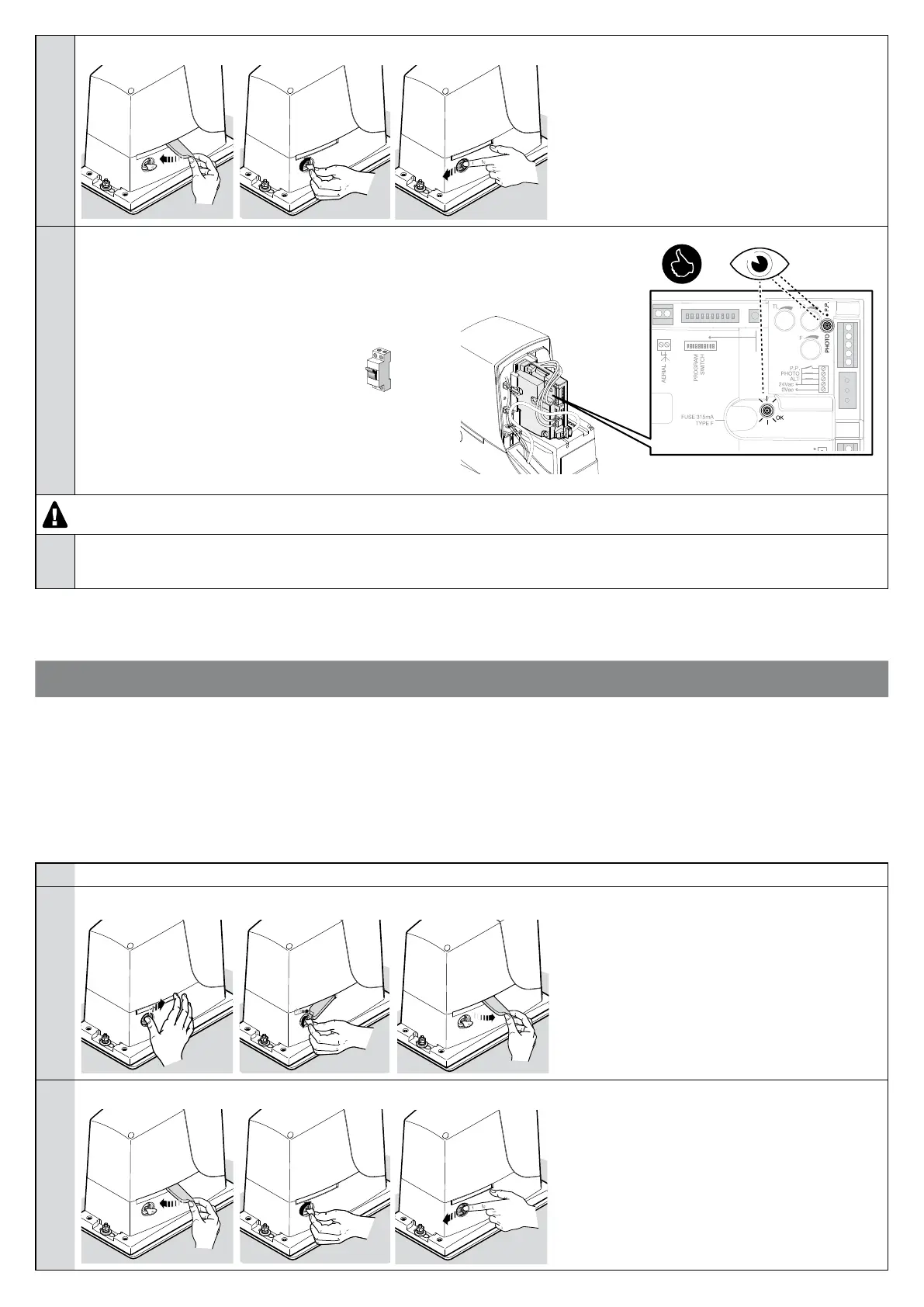

01. Ensure that all specications in chapter 1 “WARNINGS” have been observed in full

02. Check that the gate can be moved by hand in both directions with a force no greater than the value given in the application limits (Table 1)

03. Lock the gearmotor

Loading...

Loading...