English – 3

EN

Putting into operation

This can occur only after having performed, with positive results, all the inspec-

tion phases of the gear motor and other devices present. To put it into opera-

tion refer to the instructions manual of the control unit.

IMPORTANT – It is forbidden to put into partial or provisional operation.

DISPOSAL OF THE PRODUCT

This product is an integral part of the automation, and therefore, they

must be disposed of together.

As for the installation operations, at the end of the life of this product, the dis-

mantling operations must be performed by qualified personnel.

This product is made from different types of materials: some can be recycled,

others must be disposed of. Please inform yourselves on the recycling or dis-

posal systems provided for by the laws in force in your area, for this category of

product.

CAUTION! – some parts of the product can contain polluting or dangerous

substances which, if dispersed in the environment, may cause serious harm to

the environment and human health.

As indicated by the symbol at the side, it is forbidden to throw

this product into domestic refuse. Therefore, follow the “sepa-

rated collection” instructions for disposal, according to the

methods provided for by local regulations in force, or redeliver

the product to the retailer at the moment of purchase of a new,

equivalent product.

CAUTION! – the regulations in force at local level may envisage heavy sanc-

tions in case of abusive disposal of this product.

To keep the level of safety consistent and to guarantee maximum life of the

entire automation it is necessary to maintain it regularly.

The maintenance must be performed in line with the safety instructions of this

manual and according to what is set out by the laws and regulations in force.

For the gear motor a programmed maintenance within no more than 6 months

is required.

Maintenance operations:

01. Disconnect any sources of electricity.

02. Check the status of deterioration of all the materials which make up the

automation with particular attention to signs of erosion or oxidation of the

structural parts: replace the parts which do not provide sufficient guaran-

tees.

03. Check the screw connections are sufficiently tight.

04. Check the bolt and endless screw are suitably greased.

05. Check the wear of the moving parts and, if necessary, replace used parts.

06. Reconnect the sources of electrical power and perform all the tests and

checks envisaged in chapter 5.

For the other devices present in the system refer to the individual instruction

manuals.

PRODUCT MAINTENANCE

6

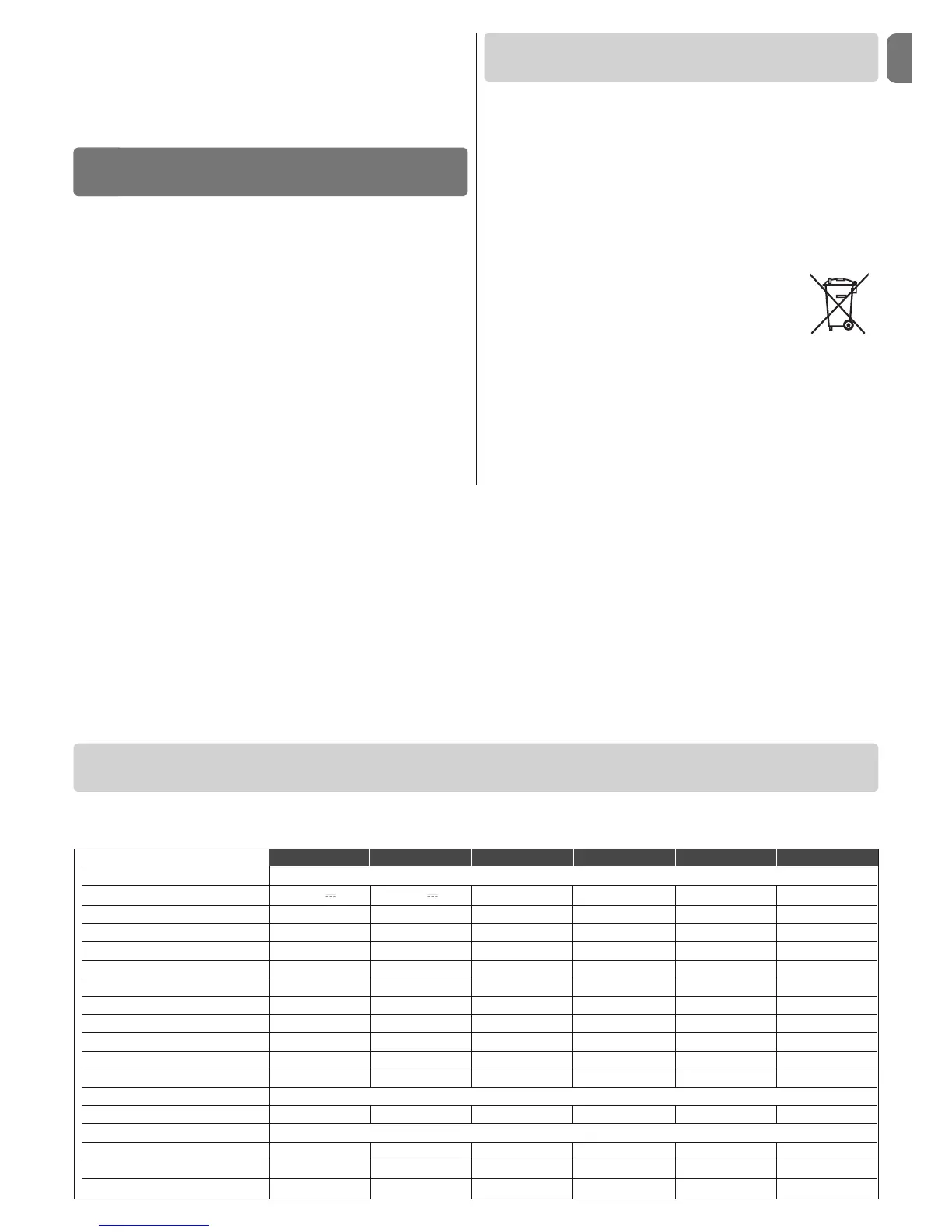

Type electromechanical gear motor for gates or doors with leaf opening

Power input 24 V 24 V 230 V~ 50 Hz 120 V~ 60 Hz 230 V~ 50 Hz 120 V~ 60 Hz

Maximum absorption 3,5 A 3,5 A 1,5 A 1,5 A 1,5 A 2,5 A

Nominal absorption 2 A 2 A 0,5 A 0,5 A 0,5 A 1 A

Maximum absorbed power 85 W 85 W 200 W 200 W 200 W 200 W

Nominal absorbed power 50 W 50 W 130 W 130 W 130 W 130 W

Protection grade IP 44 IP 44 IP 44 IP 44 IP 44 IP 44

Travel 320 mm 460 mm 320 mm 320 mm 460 mm 460 mm

Speed loadless 0,018 m/s 0,016 m/s 0,016 m/s 0,020 m/s 0,013 m/s 0,016 m/s

Speed loaded 0,013 m/s 0,012 m/s 0,012 m/s 0,015 m/s 0,010 m/s 0,012 m/s

Maximum thrust 1500 N 1500 N 1500 N 1500 N 1700 N 1700 N

Nominal thrust 500 N 500 N 500 N 500 N 600 N 600 N

Operating temperature -20 °C to +50 °C

Cycles h at nominal torque 40 40 30 30 30 30

Durability estimated between 80,000 and 250,000 cycles of manoeuvres according to the conditions set out in Table 2

Insulation class AAFF FF

Dimensions (mm) 770 x 98 x 95 h 920 x 98 x 95 h 770 x 98 x 95 h 770 x 98 x 95 h 920 x 98 x 95 h 920 x 98 x 95 h

Weight (kg) 666666

TECHNICAL FEATURES OF THE PRODUCT

WG4024 WG5024 WG4000 WG4000/V1 WG5000 WG5000/V1

CAUTIONS: • The technical features set out refer to an ambient temperature of 20°C (± 5°C). • Nice S.p.a. reserves the right to make alterations to the product

any time it deems it necessary, keeping the same functionality and destination of use.

Loading...

Loading...