FORM NO. 56043093 / Captor

™

4300, 4800, 5400 / CR 1100, 1200, 1400 -

77

77

7

ENGINE COOLANTENGINE COOLANT

ENGINE COOLANTENGINE COOLANT

ENGINE COOLANT

CAUTION!CAUTION!

CAUTION!CAUTION!

CAUTION!

Do not remove the radiator cap when the engine is hot.

To check the engine coolant level, lift the Engine Compartment Door

((

((

(

2222

2222

22

))

))

) and observe the coolant level on the Coolant Recovery

Tank

((

((

(

2323

2323

23

))

))

). If the level is low add a mixture of half water and automotive type anti-freeze. Clean the radiator and oil cooler exteriors

by washing with low-pressure water or using compressed air every 30 hours. Service Note: The oil cooler tips out for easy cleaning.

ENGINE OILENGINE OIL

ENGINE OILENGINE OIL

ENGINE OIL

Check the engine oil level when the machine is parked on a level surface and the engine is cool. Change the engine oil after the

first 35 hours of operation and every 150 hours after that. Use 3.5 quarts (3.3 liters) with filter, of any SF or SG rated oil meeting API

specifications and suited to seasonal temperatures. Refer to the Engine System for additional information. Replace the oil filter with

every oil change.

TEMPERATURE RANGETEMPERATURE RANGE

TEMPERATURE RANGETEMPERATURE RANGE

TEMPERATURE RANGE

OIL WEIGHTOIL WEIGHT

OIL WEIGHTOIL WEIGHT

OIL WEIGHT

Above 60° F (15° C) SAE 10W-30

Below 60° F (15° C) SAE 5W-30

ENGINE AIR FILENGINE AIR FIL

ENGINE AIR FILENGINE AIR FIL

ENGINE AIR FIL

TERTER

TERTER

TER

The engine Air Filter

((

((

(

88

88

8

))

))

) is located in the engine compartment. Check the air mechanical vacuum filter Service Indicator

((

((

(

4646

4646

46

))

))

) before

each use of the machine. Do not service the air filter unless the indicator is lit (red).

CAUTION!CAUTION!

CAUTION!CAUTION!

CAUTION!

When servicing the engine air filter elements, use extreme caution to prevent dust and dirt from entering the engine.

The engine air filter contains a primary (outer) and a safety (inner) filter element. The primary element may be cleaned twice before

being replaced. Replace the safety element every third time that the primary element is serviced. Never try to clean the safety

element. To clean the primary filter element, remove the cover from the dust cup end of the canister and pull out the primary element.

Clean the element with compressed air (maximum pressure 100 PSI) or wash it with water (maximum pressure 40 PSI). Do not put

the element back into the canister until it is completely dry.

ENGINE MAINTENANCE (150 HOURS)ENGINE MAINTENANCE (150 HOURS)

ENGINE MAINTENANCE (150 HOURS)ENGINE MAINTENANCE (150 HOURS)

ENGINE MAINTENANCE (150 HOURS)

At 150 hour intervals it is recommended that the following service be performed: Change oil and filter, clean and inspect spark plugs,

check all engine belts condition and adjustment, check battery charge and level, check cooling system hoses and clamps and check

general condition and performance of engine.

Note: Note:

Note: Note:

Note: Reference the separately supplied PSI GM Power Train Products Operation and Maintenance manual for more detailed

service data. PSI manual number is 3610000.

HYDRAULIC OILHYDRAULIC OIL

HYDRAULIC OILHYDRAULIC OIL

HYDRAULIC OIL

WW

WW

W

ARNING!ARNING!

ARNING!ARNING!

ARNING!

MAINTENANCEMAINTENANCE

MAINTENANCEMAINTENANCE

MAINTENANCE

To avoid hydraulic oil injection or injury, always wear appropriate clothing and eye

protection when working with or near hydraulic system.

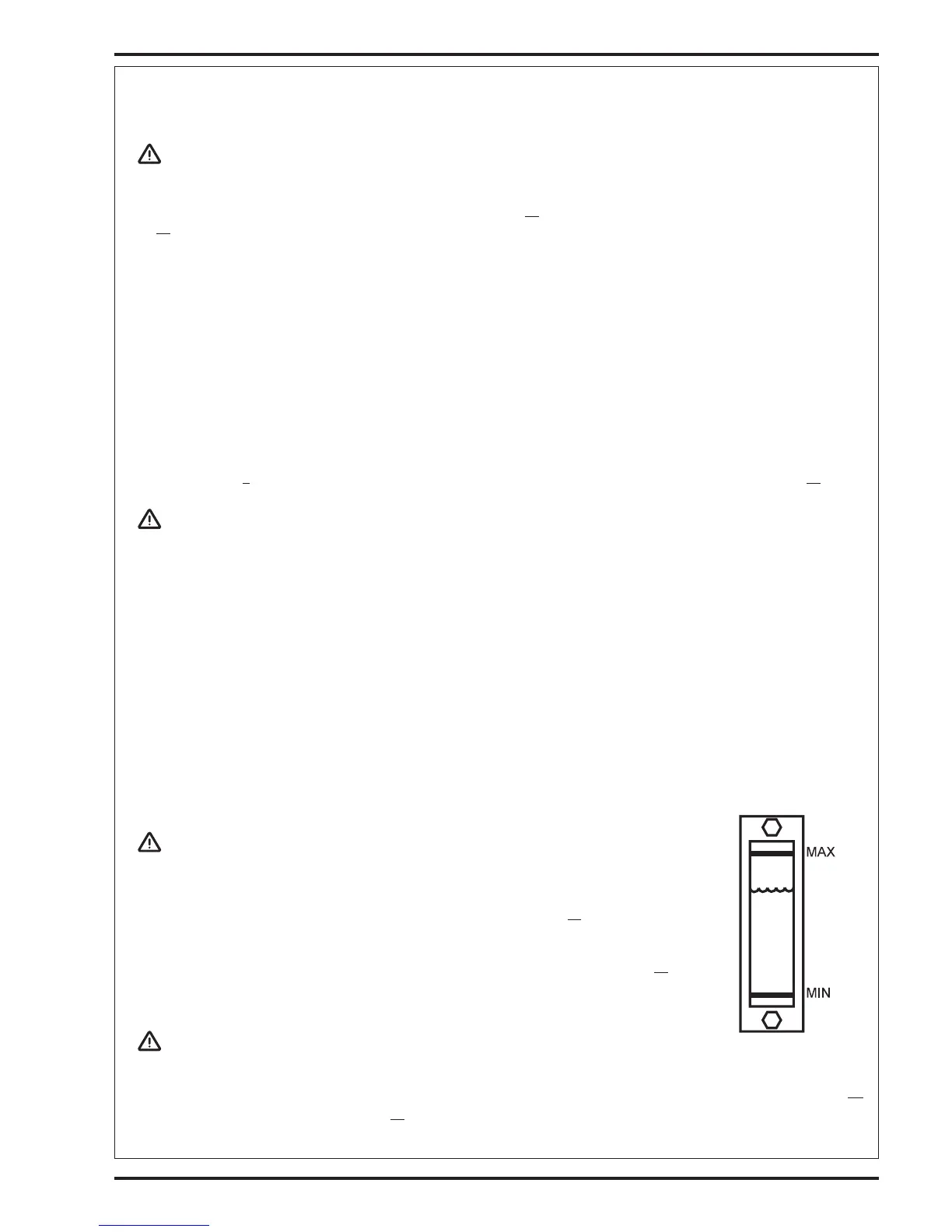

Check the Hydraulic Oil Level.Check the Hydraulic Oil Level.

Check the Hydraulic Oil Level.Check the Hydraulic Oil Level.

Check the Hydraulic Oil Level. Remove the Right Engine Access Panel

((

((

(

3737

3737

37

))

))

) and look at the

gauge on the side of the reservoir. If the oil level is below the minimum level, add 10W30 motor

oil until the gauge is 3/4 full. Do not fill above maximum. Change the oil if major contamination

from a mechanical failure occurs.

SERVICE NOTE:SERVICE NOTE:

SERVICE NOTE:SERVICE NOTE:

SERVICE NOTE: Remove the small access panel

((

((

(

4949

4949

49

))

))

)

directly above the reservoir to add oil. This panel is held on by (2) wing nuts on the underside

of the panel. Only filtered oil should be added.

IMPORTIMPORT

IMPORTIMPORT

IMPORT

ANT!ANT!

ANT!ANT!

ANT!

This machine is equipped with an indicator light which lights if the “In Tank” oil filter requires changing. Remove filter

element from the filter cup and replace with new filter. Hydraulic filter is found on top of the Hydraulic Reservoir

((

((

(

3636

3636

36

))

))

).

Change the Hydraulic “Charge” Oil Filter

((

((

(

3535

3535

35

))

))

).

Note: Oil should be warm, cold oil is thicker and may cause the light to come on intermittently until it warms up.

FIGURE 1FIGURE 1

FIGURE 1FIGURE 1

FIGURE 1

Loading...

Loading...