5

1)

Options / model variants

Original instructions

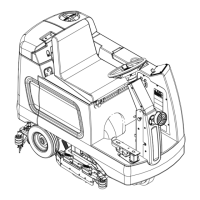

3.8 Fill up fuel tank

With the machine cold:

1. Fill fuel tank from a clean con-

tainer with a fresh fuel, heat-

ing oil, DIN 51603-1 (without

bio diesel) or Diesel EN 590

NOTE!

At temperatures below 8° C, the fuel

oil begins to solidify (paraffin precip-

itation). This can lead to difficulties

in starting the burner. Before the

winter period either add a solidifica-

tion point / flow improver (available

from the fuel oil trade) to the fuel or

use winter diesel fuel.

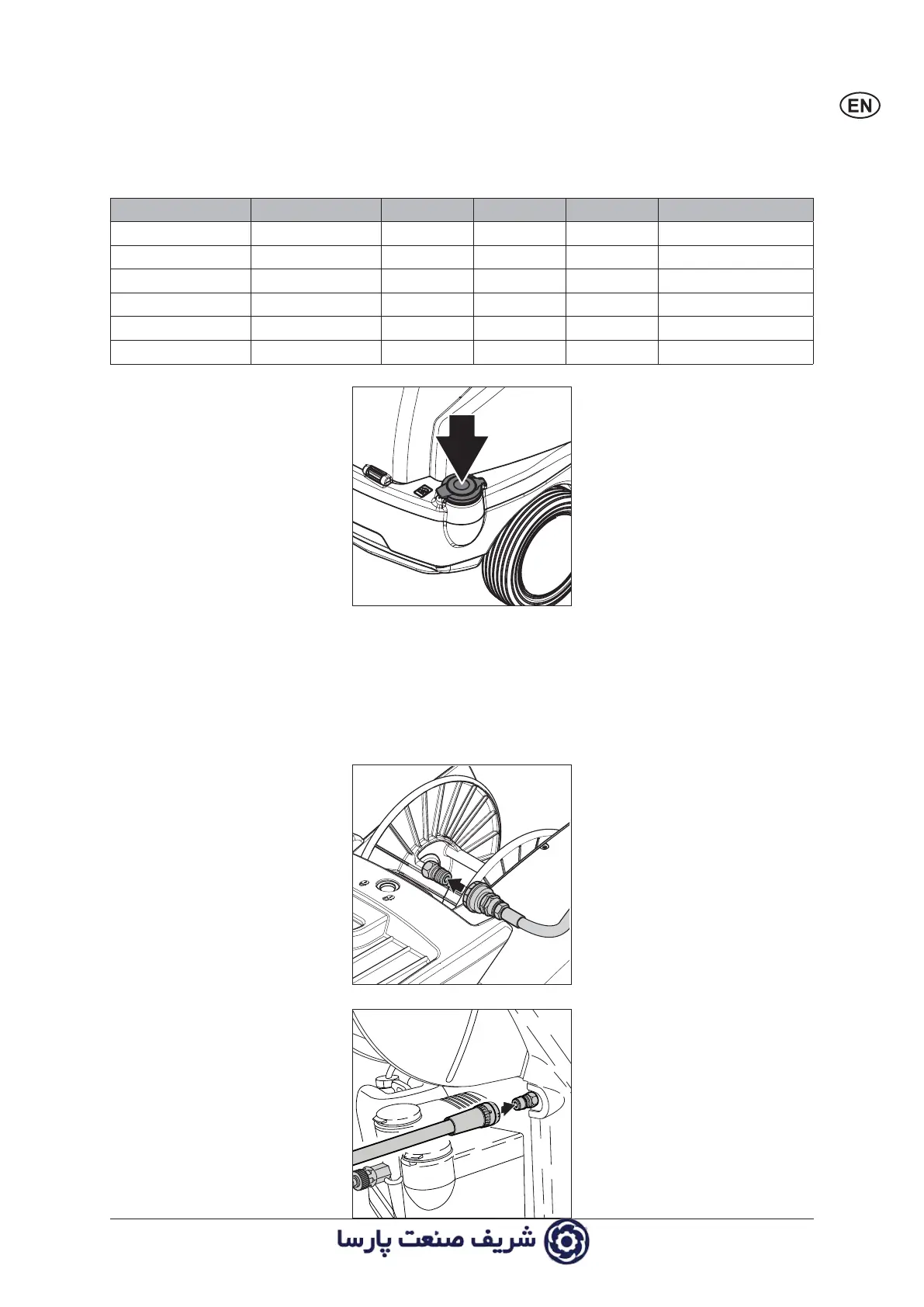

3.9 Connecting the high

pressure hose

3.9.1 Machines with high

pressure hose reel

1. Put the quick connector of

the high pressure hose onto

the nipple on the axle.

3.9.2 Machines without high

pressure hose reel

1. Put the quick connector of

the high pressure hose onto

the nipple on the cleaner.

3.7 Antiscale

The Nilfisk Antiscale dosing sys-

tem is set by the factory.

To adjust the water hardness we

recommend that the inlet water

is tested accordingly.

Use the schematic to find the

right dosage of No Scale/anti

stone and water, and add the

mixture to the antiscale tank.

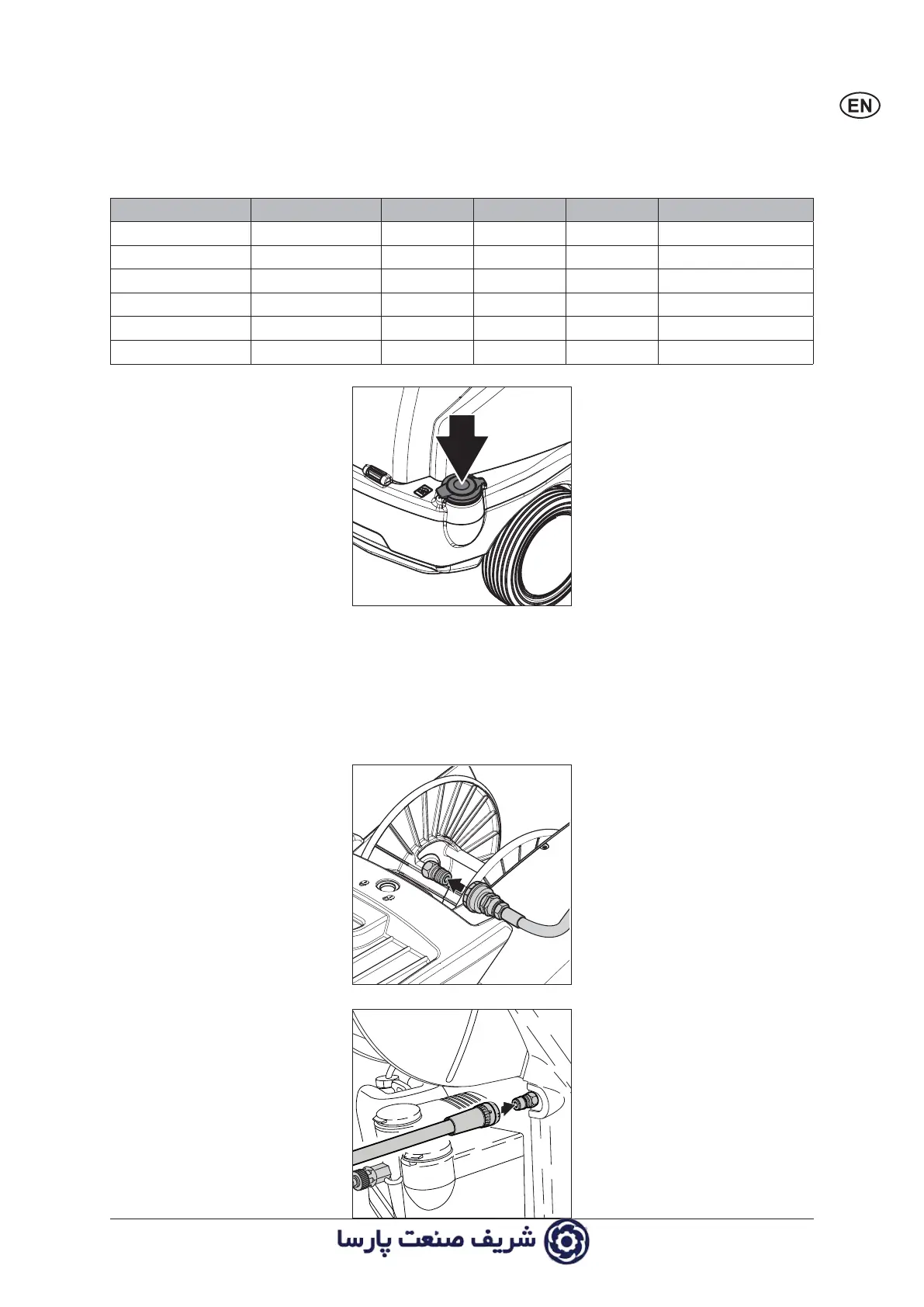

Machine flow L/h Pump size ml/h ˚dH ˚f ˚e Dosage

800 35 0-12 0-21,5 0 - 15 1:1 = 17ml/h

800 35 12-30 21,5 - 53,7 15 - 37,5 Pure = 35ml/h

900 35 0-12 0-21,5 0 - 15 1:1 = 17ml/h

900 35 12-30 21,5 - 53,7 15 - 37,5 Pure = 35ml/h

1000 35 0-12 0-21,5 0 - 15 1:1 = 17ml/h

1000 35 12-30 21,5 - 53,7 15 - 37,5 Pure = 35ml/h

(Diesel with a bio diesel con-

tent up to 7%).

Diesel according to EN 590

(up to 7% bio diesel) can be

used with the following re-

strictions: Maximum storage

time in high pressure cleaner

diesel tank: 1 month. Diesel

stored externally for more

than 6 months is not allowed

to be fi lled into Nilfi sk high

pressure cleaners. Diesel

EN 590 is not recommended

for use in HPW's at an ambi-

ent temperature below 0°C.

Diesel EN 590 from an open

container must not be used.

Loading...

Loading...