For the integrated versions, especially the larger iWBMSh 1°, take extra precaution against drops or

rough handling, especially when shipping via courier. Use “Fragile” labels where/when possible to

add further protection for the system suite.

Replace connector caps on sonar, SIU and cables when not in use to keep out debris and moisture.

Choose a dry location at room temperature for prolonged storage. Never wet store system in sealed

environment; dry the system before returning to the case. When returning to office, open the case.

CAUTION: Sonar Protection

When submerged for long periods, the sonar is at risk of becoming fouled by

barnacles etc. (especially in warm salty water) or may be subjected to stray

electric currents. NORBIT offers both titanium housing, additional anodes

and factory applied bio-fouling paint that is approved and tested against

acoustical losses. Contact subsea_support@NORBIT.com for info.

Do not leave system in the sun for long durations. Prolonged exposure to UV rays may cause

degradation of the polyurethane coating on the transducers; potential damage includes drying and

crack formation which would permanently expose and damage sensitive sonar electronics.

Never allow wet end to rest on the polyurethane as this may scratch or wear this sensitive area.

Always use a sturdy padding (foam) under the sonar when mounting it.

To clean the WBMS, only use mild, nonabrasive soap, fresh water, and a soft brush to gently scrub

the sonar. Using any other method may damage the sonar. Do not use a power washer to clean the

sonar. This can damage the housing and cause the sonar to improperly beam form.

To protect the system from corrosion, take extra care when handling to not scratch the anodized

aluminum housing (not a concern for titanium housing). It is also a good practice to rinse off the

sonar after use, especially if used in saltwater, and allow it to dry completely prior

to storage. As an added layer of corrosion protection, it is recommended that the

vessel anodes be checked on a regular basis. This will further protect the WBMS.

If the WBMS is hull mounted, NORBIT provides an option for performance neutral

antifouling paint application. Painting of the sonar outside of NORBIT may cause

negative impacts to system performance and pushes the system outside of

warranty.

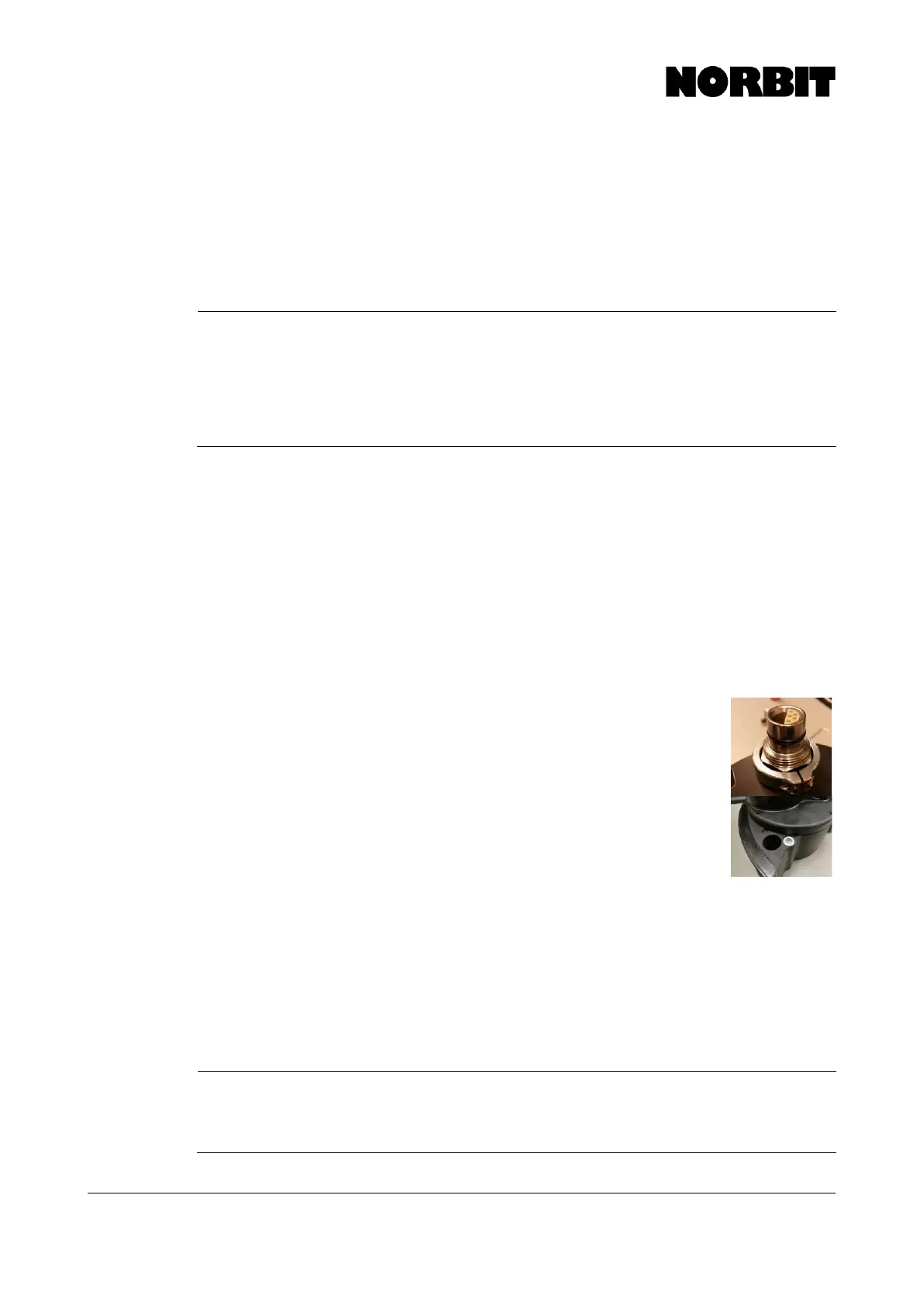

If the sonar will be in the water for extended periods, it is recommended that

sacrificial anodes be used to protect against electrolysis. Anodes can be collared

around the cable connection and the inserted into the receiver frame, as shown in the adjacent

images. Care must be taken to not scratch the anodizing on the aluminum housing during

installation. Spare anodes can be purchased directly from NORBIT.

NORBIT offers antifouling paint service. If your system is protected with antifouling paint then

additional care is required to ensure the paint is not scraped or rubbed off during mobilization,

shipping or handling. After retrieving the sonar from the water wipe down the system with a clean

towel to clear off dirt, grime, marine growth, etc. that may otherwise compromise the sonar body.

Loading...

Loading...