10.4.3 User Manual Contents April 17, 2020

Firmware: 5.2.1 Page 11 of 142

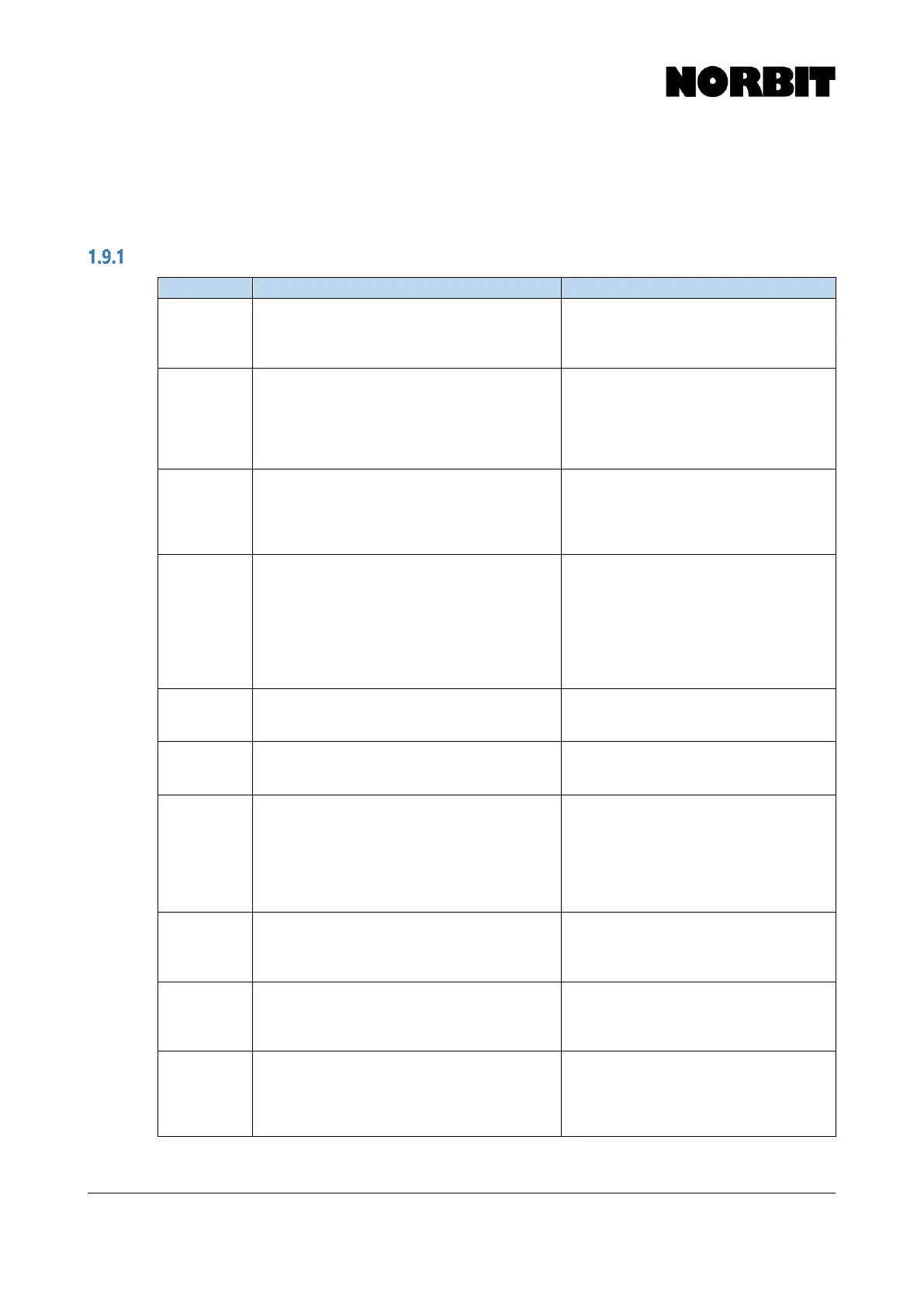

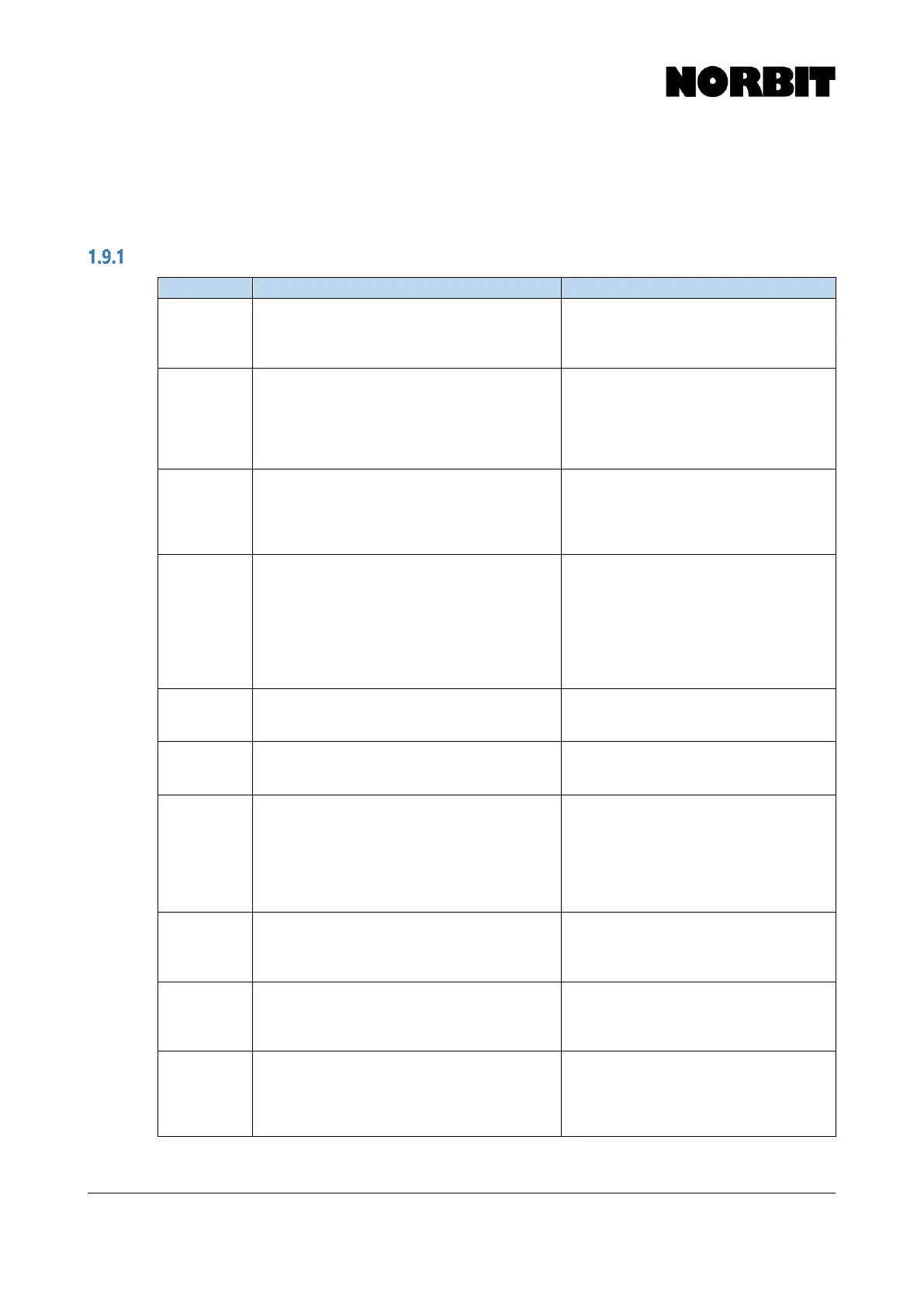

1.9

Maintenance Schedule

It is good practice to perform periodic inspections or checks of the sonar system. The table below

lists several checks, recommended by NORBIT, to guide users in performing maintenance checks.

Before Each Survey

Inspect polyurethane for gouges, nicks or

separation from housing. The array face

should be smooth and uniform.

Water intrusion will result in excessive

damage and be costly to repair. Contact

NORBIT Support for further information.

Always store sonar away from sun.

Inspect the projector array for gouges or nicks

and check the attachment area of the projector

with the sonar housing. The projector surface

should be smooth and uniform. A delamination

protection ring should be tightly fitted to

projector at the housing attachment point.

Water intrusion will result in excessive

damage and be costly to repair. Contact

NORBIT Support for further information.

Always store sonar away from sun.

O-Rings on

wet end

cable

connections

Check O-rings for damage and particulates

that may interfere with O-ring operation and

keep it lightly lubricated. Use Silicone Grease

that is min 90% pure.

If missing a spare O-ring, please remove

and borrow one from the cable wet-end

protective cap. But be sure to get the

appropriate one replaced from NORBIT

support.

Remove sound speed probe and check

connector for corrosion. Probe O-ring should

be in good condition. Replace probe and

ensure a tight fit. Apply light coating of silicone

grease to O-ring prior to re-attaching probe.

Compare value with value from profiler at

same depth. Difference should not be greater

than 1m/s

Bad or missing surface sound speed will

create beam steering errors and affect

outer swath data performance. It is

recommended that the probe be

calibrated every 18-24 months.

Inspect housing for scratches and corrosion.

Ensure anode is in good condition (for

aluminum housing).

Small scratches compromise the galvanic

barrier of the aluminum housing. Contact

NORBIT for further information.

Check for debris and clean out with

compressed air. Cable connector must be dry

and clean. Use protective cap when not in-use.

Sonar connection is not wet-mateable.

Do not disconnect or connect when sonar

is submerged or in wet areas.

Check connectors and clean out with

compressed air. Run cable through hand and

check that cable is smooth, without kinks and

without tears. Check that pins are shiny and

not bent. Check O-rings for wear and replace

as necessary. Use small amount of silicone

lubricant.

A bad connection or bad cable will

corrupt survey data. Treat the cable with

great care (do not walk on it).

Check that threads on plastic sleeves are in-

tack and not de-threaded. Vibration over long

term can loosen bolts and compromise data

quality or loss of wet-end.

Use only stainless-steel bolts and

washers. Contact NORBIT for spare

parts. Use Loctite 242 Blue, lock washers

and/or nylon nuts.

Check that all hardware for the mounting

bracket is tight. Care must be taken when

checking the mounting screws for the sonar as

over tightening may damage the connections

The bracket is very robust and provides

electrical isolation from the vessel.

Electrical &

Galvanic

Isolation

Shield

Check that plate is included in shipping case

and used between sonar and sonar bracket

when mounted. For the WBMS (non-integrated

systems), it is imperative to use the included

electrical isolation shield.

This protects the aluminum sonar

housing from galvanic corrosion.

Loading...

Loading...