Nordson Asymtek

Mini and micro dispensing solutions for fluids and pastes

page 6 off 20

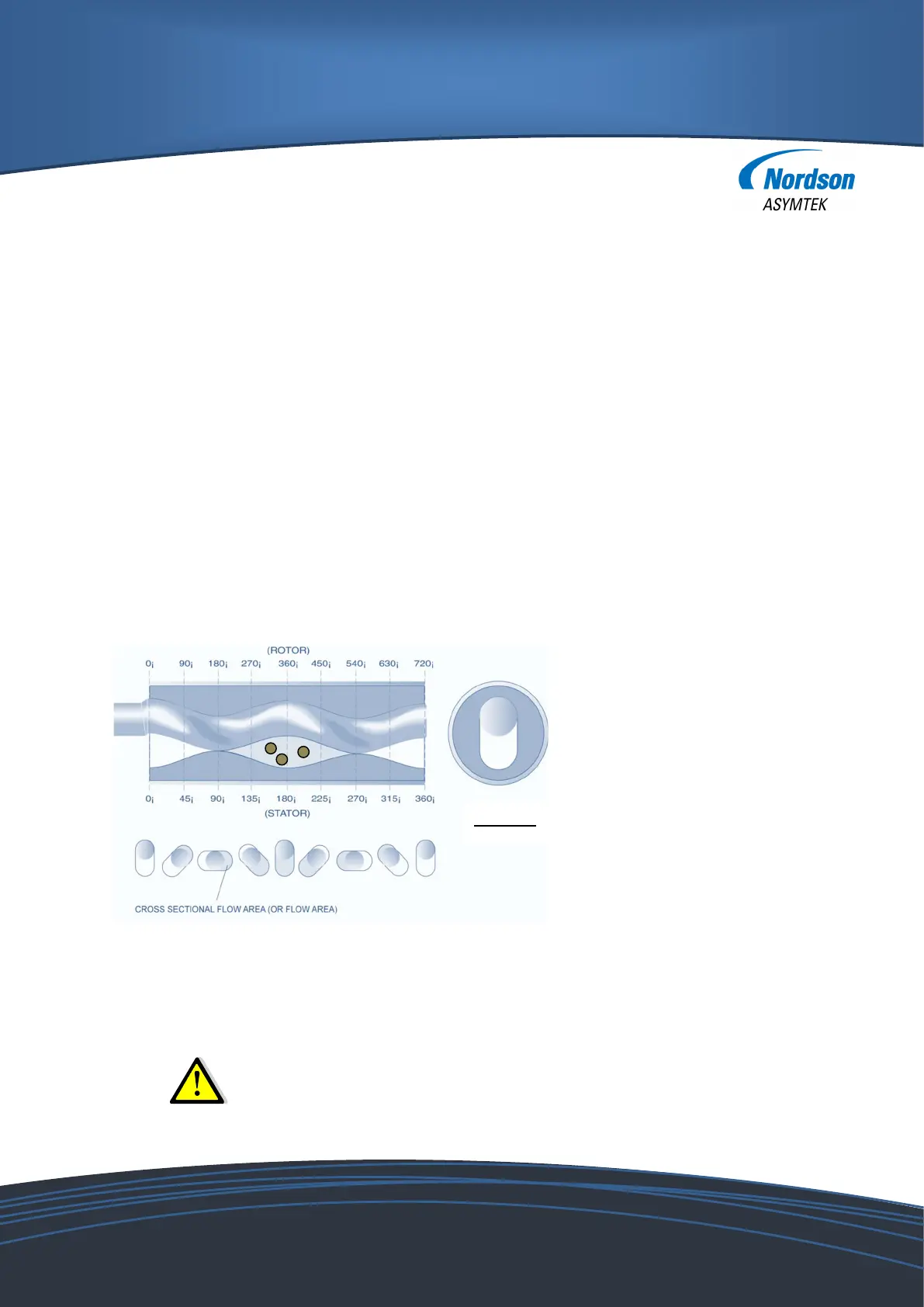

ASYMTEK Dosing technology is based on the endless dosing progressing cavity pump. The

rotating element “Rotor” and the static counter part “Stator” form an optimal chamber

“Cavity”. Both rotor and stator touch eachother over the whole length to create a continuous

seal that prevents backflow even with higher back pressure. The movement of the rotating

rotor in the stator allows the fluid to be gently pushed to the next chamber without shearing

and squeezing the fluid. (picture 1).

Due to the fact that the cavity along the sealing line is always open, particles can be handled

without difficulties. ASYMTEK technology will pump and dose abrasive fluids but also more

viscous pastes whenever the chambers are correctly and completely filled.

ASYMTEK Rotors are manufactured to resist many chemical materials according CE

conformity. The high degree of smoothness of the rotor surface prevents fast wear and tear

and provides long life cycle time.

ASYMTEK Stators have been developed to offer less friction.

Driving the pump counter clockwise CCW conveys the fluid or paste from the suction side

towards the pressure side in picture 1 from left to right. To empty vessels or bottles, in

general the flow should go from right to left meaning clockwise CW. ASYMTEK pumps can

be used in continuous or indexed applications.

Picture1:

Shows the possibility to convey

particles and a gentle flow of the

material (yellow).

The dosing volume is

independent of the rotor(blue)

position since the cavities have a

defined volume.

Therefore, PCP technology is

optimal for dispensing.

Avoid dry running! Do not test with water!

Loading...

Loading...