Maintenance Instructions

42

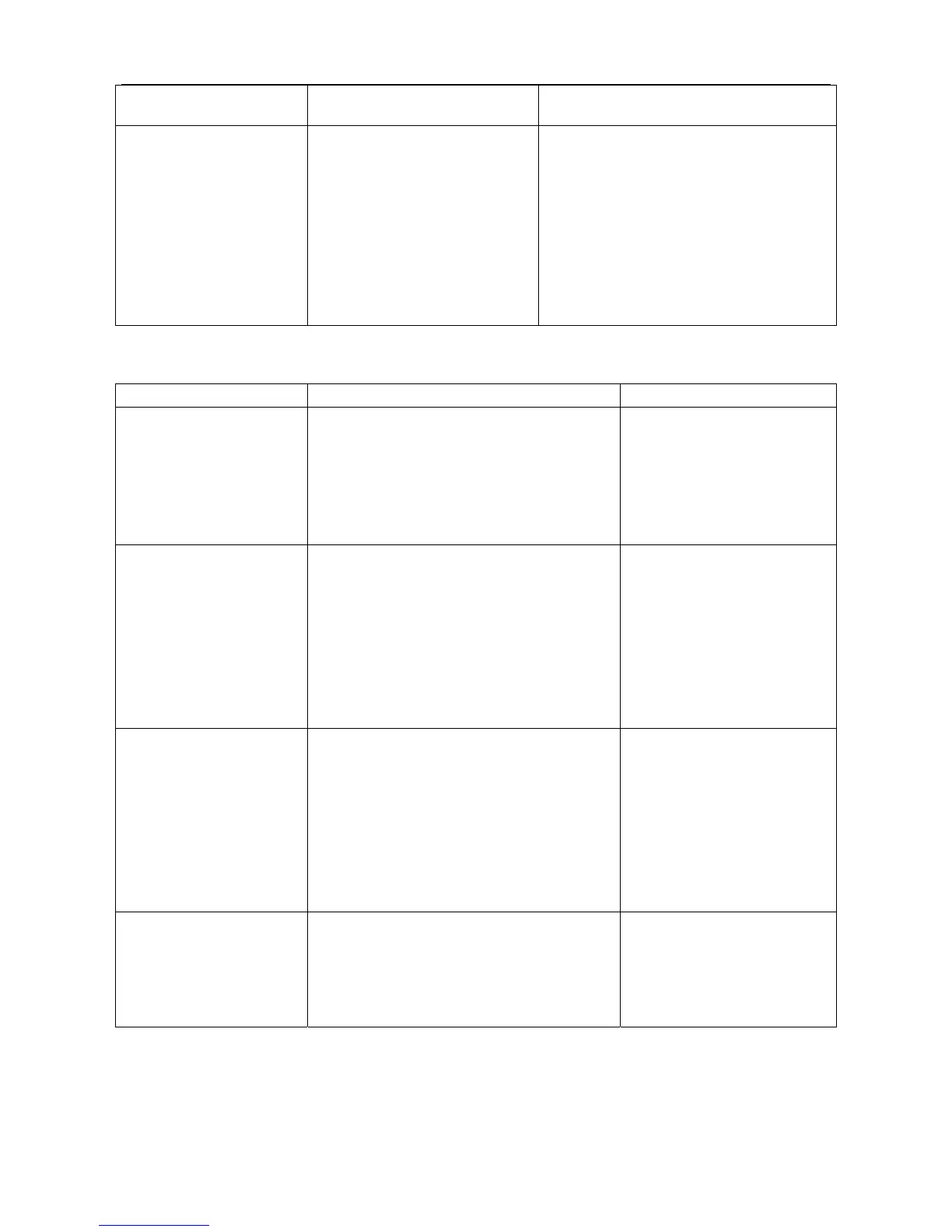

Fault Causes Troubleshooting

3. The tractor shakes when

starting.

(1) The heads of the three clutch

fingers are not in the same plane.

(2) The clutch plate and the clutch

fingers have grease on them.

(3) The clutch fingers are warped.

(4) The fastening screw for the

flywheel and the clutch has come

loose.

(1) Make adjustments according to

requirements.

(2) Clean the friction plate and the clutch

fingers with solvent.

(3) Replace the clutch fingers.

(4) Stop the tractor immediately and repair

the fault.

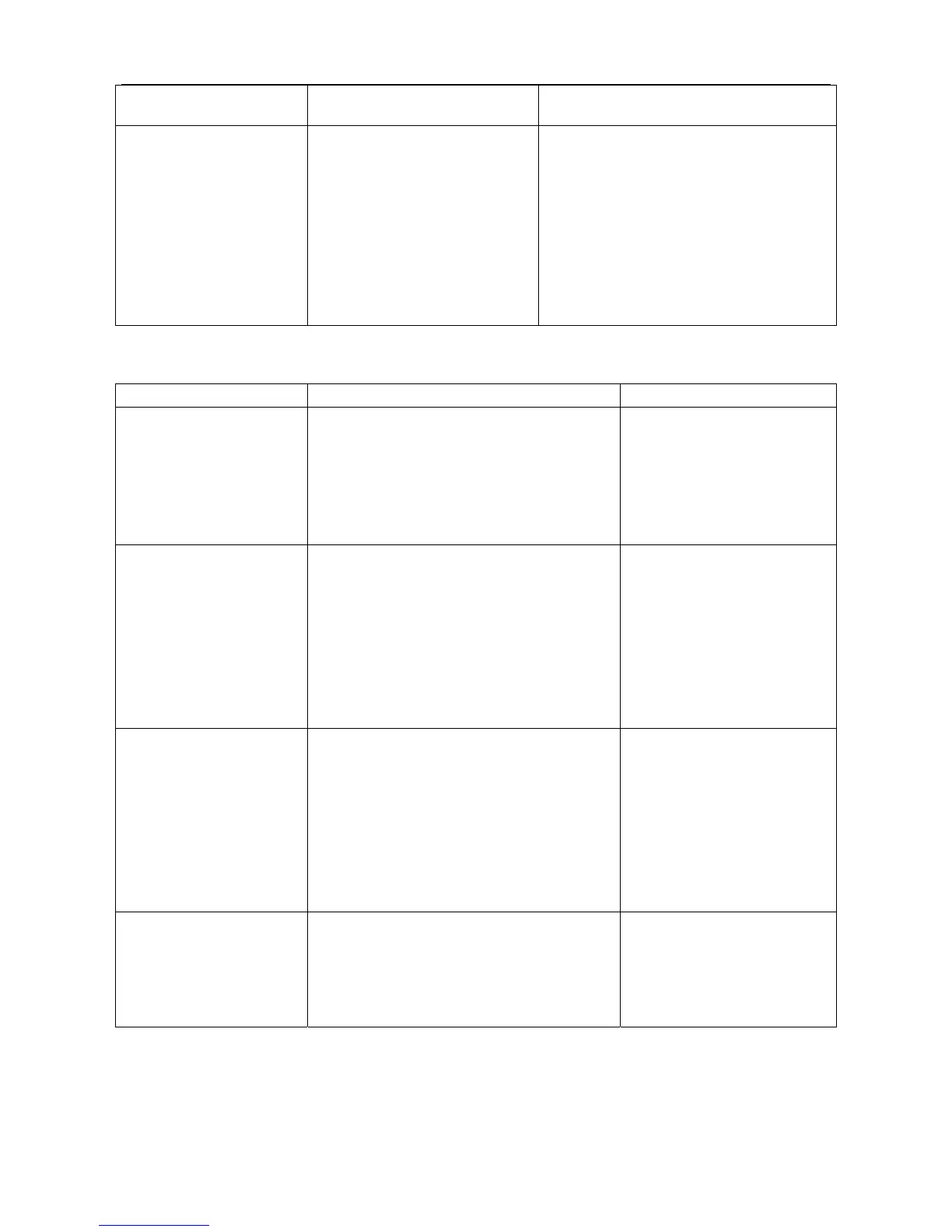

2.16.1.2 Gearbox Faults and Troubleshooting

Table 2-3 Gearbox Faults and Troubleshooting

Fault Causes Troubleshooting

1. Putting the tractor into

gear is difficult or

impossible.

(1) Clutch has not disengaged completely.

(2) Gearshift interlocking rod is too long.

(3) The shift lever fork is severely worn.

(4) The end face of the engagement sleeve or

the end face of the gear is worn or broken.

(1) Troubleshoot according to

the clutch type.

(2) Shorten the gearshift

interlocking pull rod.

(3) Replace the shift lever.

(4) Replace or repair.

2. Gearshift disengages

automatically.

(1) The gearshift interlocking rod is too short.

(2) The locating slot of the shifting fork shaft is

severely worn.

(3) The spring pressure of the interlocking latch

is insufficient.

(4) The bearing on the gear shaft is worn,

making the shaft tilt.

(5) The spline of the tooth holder is worn.

(1) Lengthen the gearshift

interlocking pull rod.

(2) Replace the shift fork.

(3) Adjust or replace the

interlocking pin spring.

(4) Replace the bearing.

(5)Replace the tooth holder.

3. Random gear shifting.

(1) The shift lever fork is worn.

(2) The gear guide plate is severely worn.

(3) The fork slot of the shifting fork and the

meshing bush are worn.

(4) Locating pin of interlocking pin and shift

fork is severely worn.

(1) Repair or replace the shift

lever.

(2) Replace the gearbox guide

plate.

(3) Replace the shifting fork and

the meshing bushing.

(4) Replace the interlocking pin

and the shift fork shaft.

4. Noise or impact sound

from the gear box.

(1) The gear is excessively worn and/or the

tooth surface has chipped off.

(2) The bearing is badly worn or damaged.

(3) The lubricating oil is insufficient or oil

quality does not conform to the specifications.

(1) Replace the gear.

(2) Replace the bearing.

(3) Fill or replace lube oil.

Loading...

Loading...