Maintenance Instructions

46

5. Steering is slow to

respond or hard to turn.

(1) The clearance between the valve core and

the valve housing is too large.

(2) The clearance between the interlocking shaft

and the fork pin is too large.

(3) The clearance between the interlocking shaft

and the rotor is too large.

(4) The return spring is broken or too soft.

(1) Replace valve.

(2) Replace shaft or pin.

(3) Replace shaft or rotor.

(4) Replace.spring.

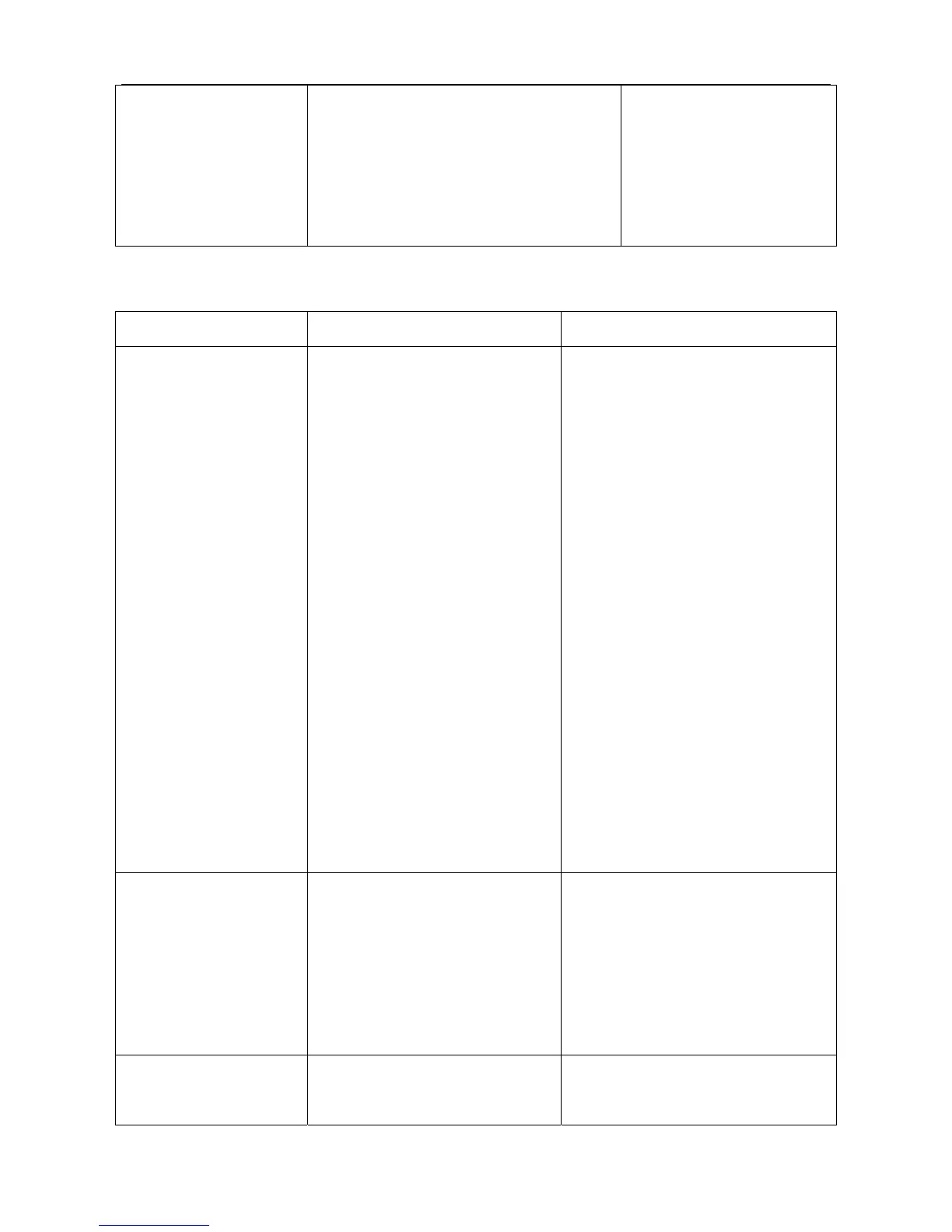

2.16.1.6 Hydraulic Hitch System Faults and Troubleshooting

Table 2-7 Hydraulic Hitch System Faults and Troubleshooting

Fault Causes Troubleshooting

1. Unable to lift either a

light or heavy load.

(1) The oil level within the 3-point lift

is too low.

(2) The strainer of the oil filter is

blocked.

(3) Air is getting into the oil suction

line.

(4) Gear oil pump failure.

(5) Spring pin on the outside/inside

end of the operation handle has fallen

out.

(6) The swing rod inside the

hydraulic distributor dropped.

(7).The main control valve seized at

the middle or lowering position, or the

oil return valve seized in the open

position.

(8) Main control valve seized.

(9) Lowering valve seized.

(10) Pin shortened, or lowering valve

assembly comes loose making it

unable to open the lowering valve.

(11) The oil passage from the cylinder

end to oil cylinder is closed.

(1) Add oil to the specified oil level.

(2) Clean or replace the strainer on the oil

filter.

(3) Check for air leaks.

(4) Replace the geared oil pump.

(5) Reinstall the spring pin.

(6) Open the distributor, and install the

swing rod.

(7) Take apart the distributor, and clean

each valve.

(8) Clean main control valve.

(9) Clean lowering valve.

(10) Remove plug for lowering valve,

readjust the clearance of the lowering

valve push pin or tighten the lowering

valve assembly.

(11) Open the oil passage.

2. Light load can be lifted,

but heavy load cannot be

lifted or lifts slowly.

(1) Air is entering the oil suction line.

(2) Adjustment pressure of the system

safety valve is too low.

(3) Adjustment pressure of the oil

cylinder safety valve is too low.

(4) Gear oil pump is worn or pressure

is inadequate.

(5) Oil cylinder seal ring is leaking.

(1)Check the oil suction pipe and oil

filter.

(2) Replace the system safety valve.

(3) Replace the oil cylinder safety valve.

(4) Replace the geared oil pump.

(5) Replace the seal ring on the oil

cylinder.

3. Farm implements shake

during lifting and/or lift

slowly.

(1) Oil filter is blocked.

(2) Air getting into the oil suction

pipe.

(1) Replace the filter element.

(2) Replace the O-ring seal.

(3) Replace the gear oil pump.

Loading...

Loading...