Caution

・ Be sure to hold the handpiece firmly to prevent the handpiece from

slipping out of hand by the spray pressure when lubricating.

・ Supply lubricant until it comes out of the handpiece head

(for approx. 2 – 3 seconds).

・ Hold the Lubricate spray can upright.

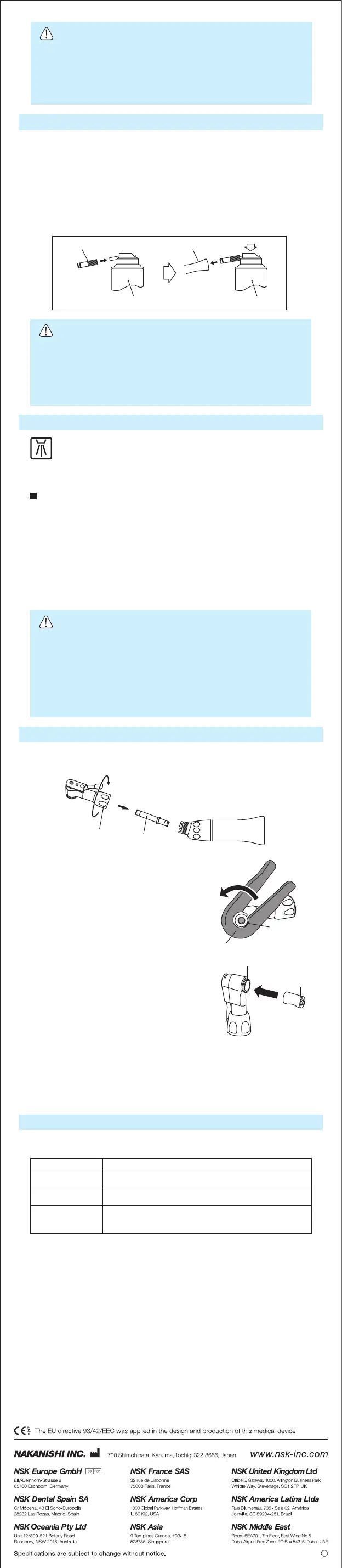

PANA SPRAY Plus / PANA SPRAY

Supply “PANA SPRAY Plus /PANA SPRAY” after each use and/or before

autoclaving.

1) Push E-type Spray Nozzle attachment over the lubricant spray

nozzle until it firmly seats.

2) Remove the bur.

3) Insert the E-Type Spray Nozzle in the rear of the handpiece and

spray for approximately 2 – 3 seconds until the oil comes out of the

handpiece head.

6. Lubrication

Fig.4

PANA SPRAY Plus/PANA SPRAYPANA SPRAY Plus/PANA SPRAY

E-type Spray Nozzle

Handpiece

Caution

・ Do not use the handpiece when the end cap is loose.

Using the handpiece under such condition will cause looseness of

the internal parts in the handpiece head, which may cause the end

cap to come off and patient’s accidental ingestion.

・ To avoid injury, keep your hands away from the bur during rotation.

Caution

・ Do not wipe nor immerse the handpiece in acidic water or acidic

solutions.

・ Keep the product in suitable atmospheric pressure,temperature,

humidity, ventilation, and sunlight. The air should be free from dust,

salt and sulphur.

・ Do not touch the product immediately after autoclaving as it will be

very hot and must remain in a sterile condition.

Steam autoclave is recommended.

Sterilization is required first time you use and after each patient.

Autoclave Procedure :

1) Scrub dirt and debris from the handpiece, and wipe clean with

alcohol-immersed cotton swab or cloth. Do not use a wire brush.

2) Lubricate the handpiece. Refer to 6. Lubrication.

3) Insert into an autoclave pouch. Seal the pouch.

4) Autoclavable up to max. 135°C.

ex.) Autoclave for 20 min. at 121°C or 15 min. at 132°C.

5) Keep the handpiece in the autoclave pouch to keep it clean until you

use it.

* NSK recommends Class B sterilizers as stated in EN 13060.

7. Sterilization

The products listed below are washable with Thermo Disinfector.

ECM, ER4M, ER10M, ER16M, ER64M

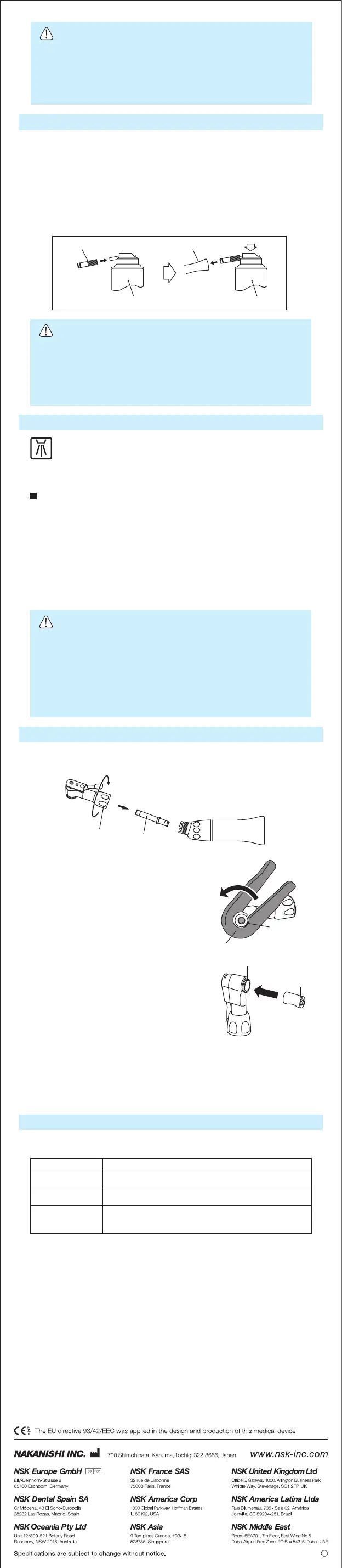

1) Loosen the Union Nut and remove the head from the sheath.

Pull out the Middle Gear from the head. (Fig. 5)

8. Cartridge Replacement (NAC,BB,NBBW)

Fig.5

Fig.6

Fig.7

Cap Wrench

Slit

Pin

End Cap

9. Periodical Maintenance Checks

Every 3 months perform periodical maintenance checks, referring to the check

sheet below. If any abnormalities are found, contact your Authorized NSK Dealer.

Rotation

Points to check Details

Check the union nut on the head is firmly tightened.

Check the end cap is firmly tightened.

Rotate the handpiece and check for abnormalities such as

abnormal rotation, vibration, noise, and overheating.

End cap is loose

Union nut is loose

Middle Gear

Union Nut

2) Place Cap Wrench on the End Cap and turn

counter-clockwise. Unscrew and remove

the cap. (Fig. 6)

3) Swing to open the latch plate. Insert a bur

blank or round rod into a hole from the head

end, and push out the cartridge.

At this time, if the inside of the head is dirty,

clean the inside by applying PANA SPRAY

Plus/PANA SPRAY.

4) Insert the new cartridge, with its pin aligned

in the slot of the head. (Fig. 7)

5) Mount each part in a reverse procedure to

the removal procedure, and firmly tighten

the end cap with the cap wrench.

* Cartridge (NAC-03) NAC-Y : Order Code C030011

(BB-03) BB-Y : Order Code C037015

(NBB-03) NBBW-Y : Order Code C210015

* Cap Wrench(Black) : Order Code C071751

* Middle Gear (NAC-02) NAC,BB,NBBW : Order Code C032012

2017.04.28 03

M

Loading...

Loading...