2 3

ENGLISH GERMAN FRENCH SPANISH ITALIAN

2. Connecting/Disconnecting handpiece and Motor

2-1 Connecting

1

)

Align the handpiece and motor alignment pin.

2

)

Then push the handpiece directly into the motor in alignment with the pin.

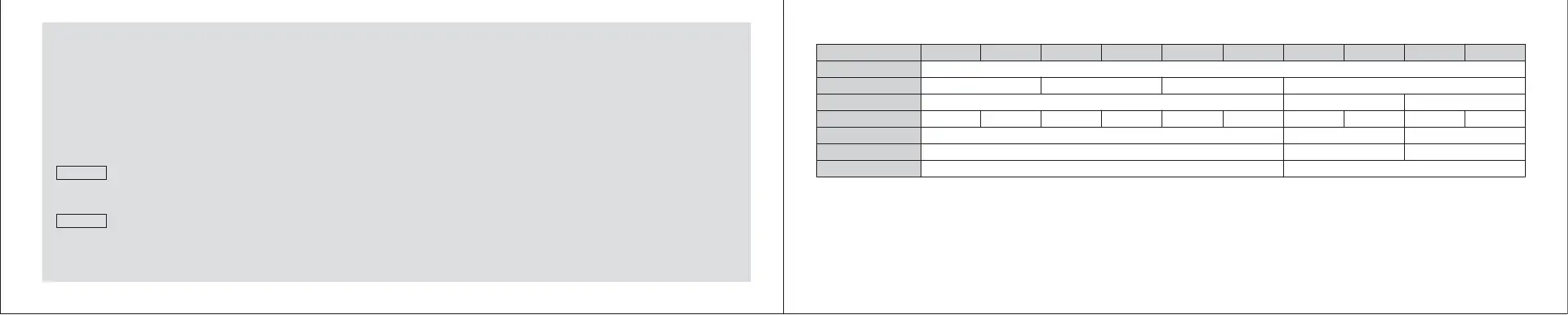

1. Specification

· Always keep bur shanks clean. Dirt or debris in a chuck could cause poor bur concentricity or low chuck retention force.

· Do not exceed the drive motor speed recommended the bur manufacturers.

· Before use always confirm that the bur is correctly seated and locked into place.

· Always use with adequate water supply and coolant air or damage to the tooth structure may occur and overheating.

· Use eye protectors, dust mask, for safety and health during treatment.

· Perform periodical maintenance checks.

· If the handpiece has not been used for a long period, check for noise, vibration, and overheating before use.

· Do not wipe nor immerse the handpiece acidic water or acidic solutions.

· User is responsible for operation, maintenance and safety.

Z85,Z85L

Use short shank FG Bur for a mini head. If long bur has used, it may cause of the omission of early wear of a bearing, Bur will bend, and

breakage.

Z95,Z95L

· Do not use long surgical burs. Do not use burs longer than 26mm.

· If a foreign material enter to the gear and inside of handpiece, it may become a cause of burn injuries.

ISO 1797-1 Type3 Ø1.60mm FG Bur

Model

Max. Rotation Speed

Gear Ratio

Bur

Optic

Bur applied Length

Max Bur Length

Max Bur diameter

Z10L

16:1

12.5mm

22.5mm

ISO 1797-1 Type1 Ø2.35mm Contra Bur

Ø4.0mm

4:1 1:1

9.8mm 10.5mm

16.5mm 25mm

1:5

40,000min

-1

Z10 Z15L Z15 Z25L Z25 Z85L Z85 Z95L

ISO 1797-1 Type3 Short Shank FG Bur

Ø2.0mm

Z95

OPTIC

NON-OPTIC

OPTIC

NON-OPTIC

OPTIC

NON-OPTIC

OPTIC

NON-OPTIC

OPTIC

NON-OPTIC

Loading...

Loading...