Lx Series Installation and Operation Instructions │Trinity Lx

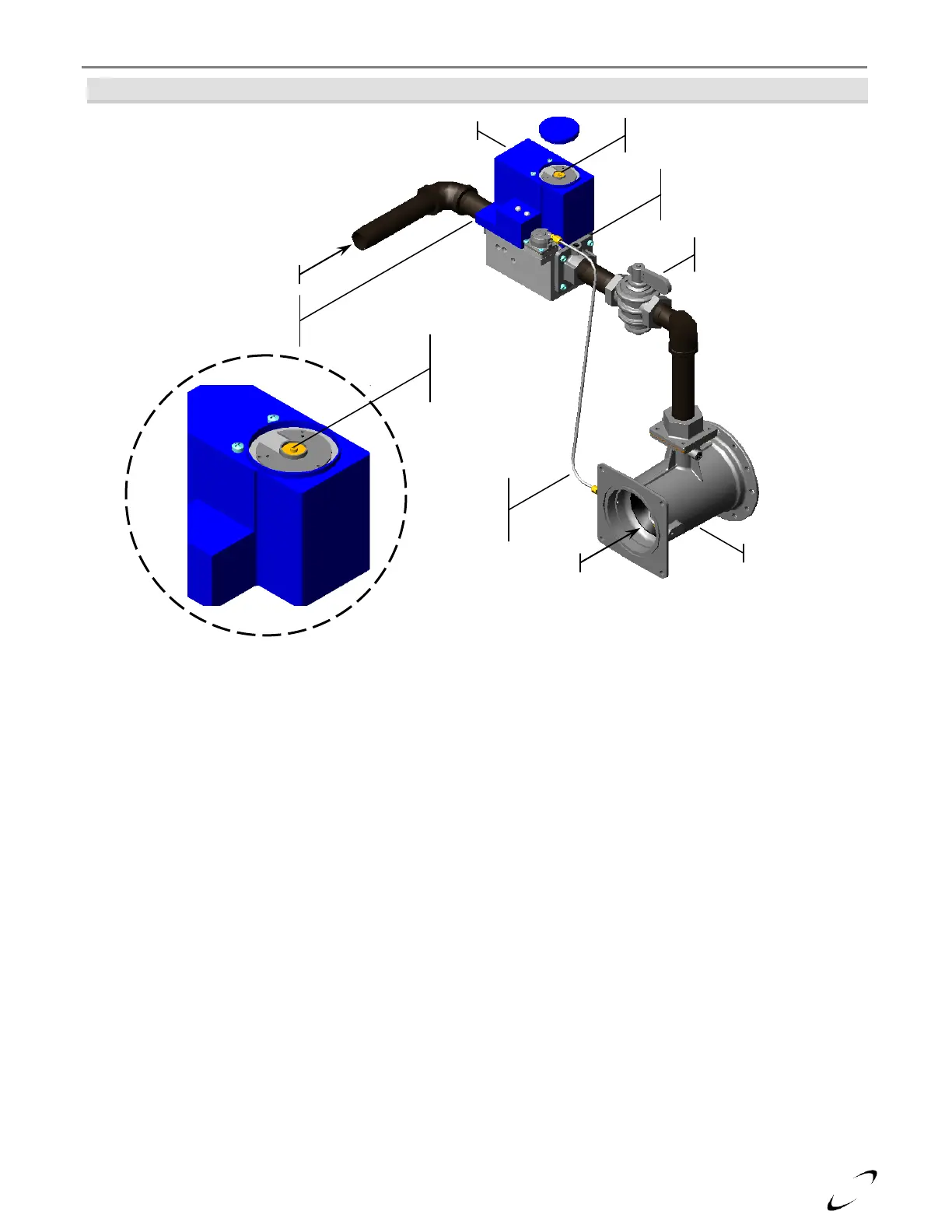

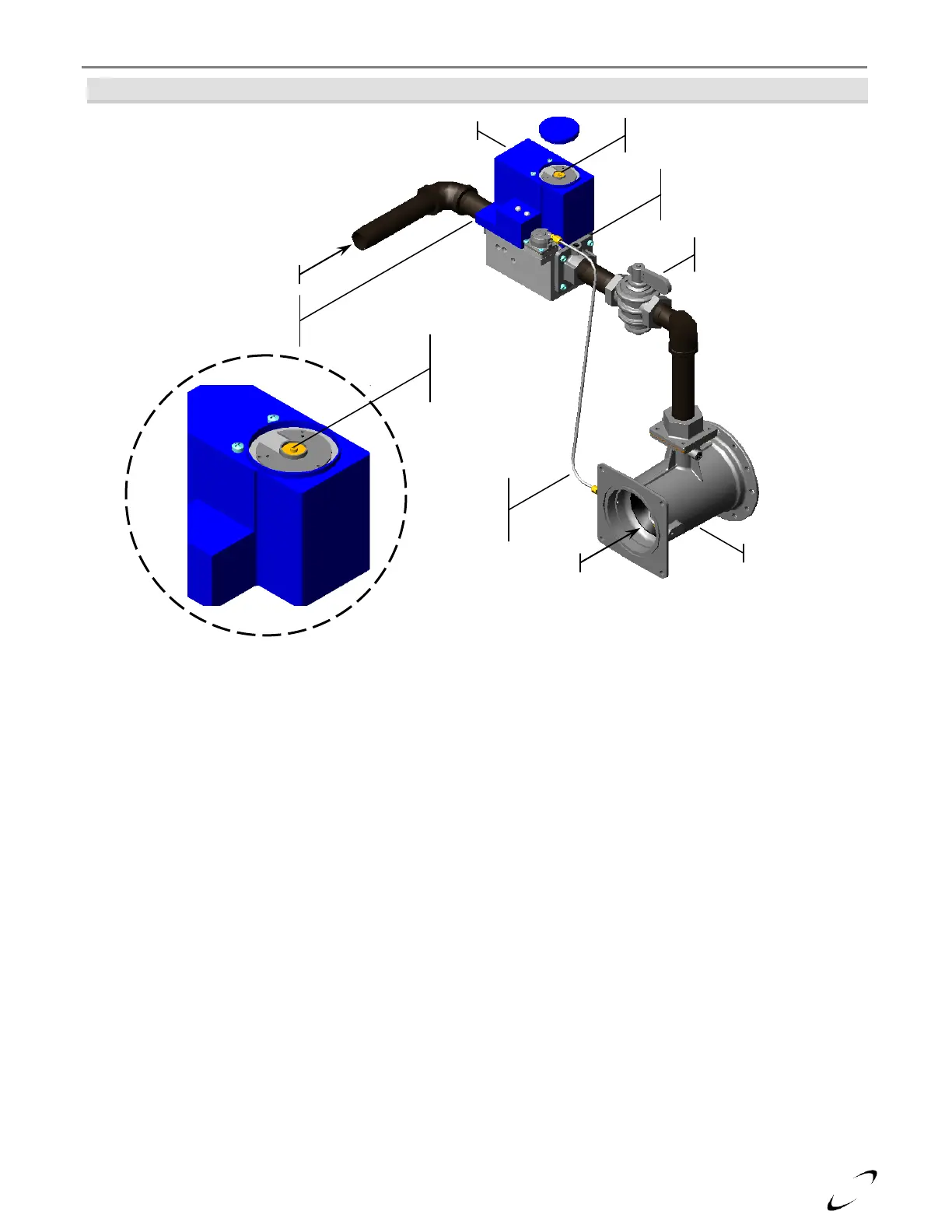

Figure 9-5 Gas Valve and Venturi Assembly (Lx600-800)

Adjustment

Input Screw Adjustments - The boiler is equipped with a Throttle/Input Adjustment Screw, located on the Gas

Valve and Venturi Assembly. The Throttle screw is used to adjust the flow of gas leaving the gas valve,

entering the Venturi and hence entering the combustion air stream. By turning the adjustment screw in,

clockwise, the flow of gas is reduced and the combustion becomes leaner, thus reducing the concentration of

CO

2

in the flue gases. To increase the CO

2

the Throttle screw must be adjusted out, counterclockwise, thus

increasing the flow of gas from the gas valve to the combustion air stream. See Figure 9-6 for screw direction.

Lx150-300 Adjustments - The throttle screw for models Lx150-300 is a multiple turn valve. Typical adjustment

required for Natural Gas is 0-1 full turns in or out from the factory setting. Typical adjustment for LP Gas is

0-3 full turns in or out from the factory setting upon inserting the LP orifice as per the applicable Propane

conversion instructions. See Figures 9-1 and 9-2 for throttle screw location.

Lx400 Adjustments - The throttle screw for the Lx400 is a geared valve with a 4:1 ratio. Adjusting the throttle

screw 4 complete turns will return the valve to the original location, 2 turns from fully open will completely

close the valve. Typical adjustment required is 0-1/4 turn in or out from the factory setting. See Figure 9-3 for

throttle screw location.

Lx500 Adjustments – The throttle screw for the Lx500 is a multiple turn valve. Typical adjustment required for

Natural Gas is 0-1 full turns in or out from the factory setting. To adjust combustion for Propane Gas, turn

the throttle screw all the way in (clockwise until it stops), then turn the throttle screw out (counterclockwise)

4-1/2 turns and set with a combustion analyzer. See Figure 9-4 for throttle screw location.

Lx600-800 Adjustments - Remove the cap and adjust the input screw by turning it clockwise to decrease gas

flow and counter-clockwise to increase gas flow. Typical adjustment required is 0-1/8 turns in or out. See

Figure 9-5 for throttle screw location.

Throttle/Input

Adjustment Screw

Manifold Pressure

Test Port (outlet

flange)

Line Pressure

Test Port

(inlet flange)

Remove cover to

make adjustments

to the throttle/input

screw

Gas Valve

Regulator

Sensing

Tube

Loading...

Loading...