Trinity Lx │Installation and Operation Instructions Lx Series

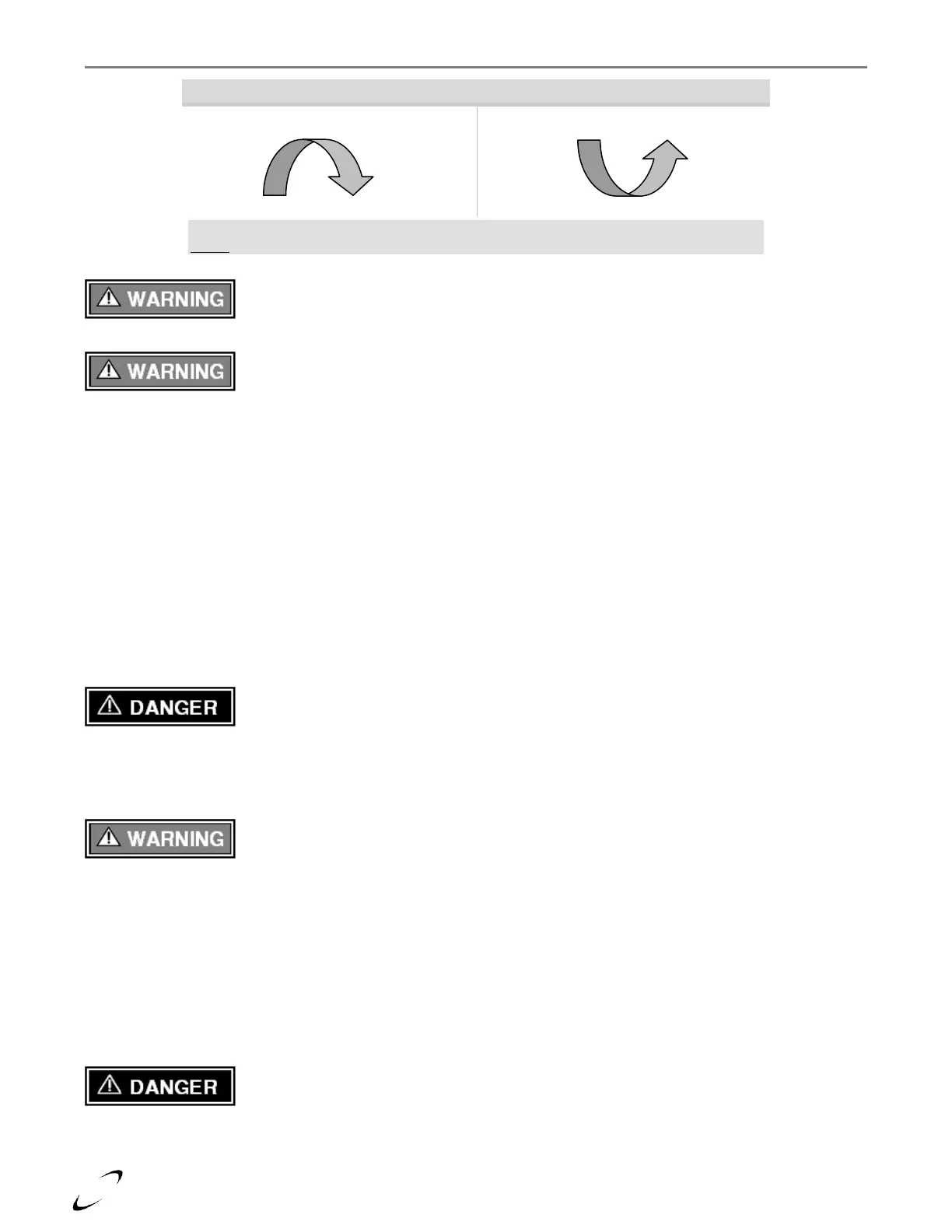

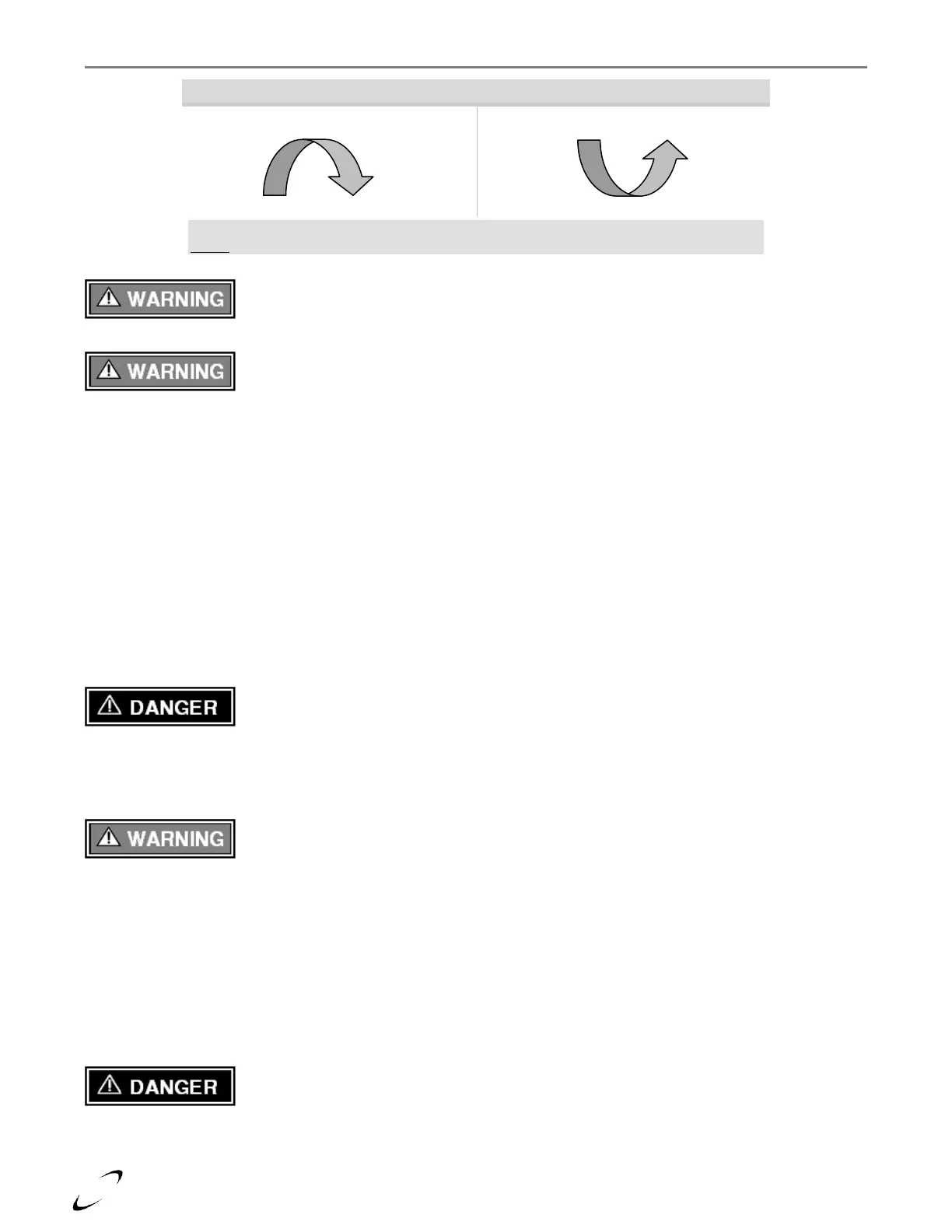

Figure 9-6 Throttle/Input Adjustment Screw (All Models)

Decrease Gas - Turn Clockwise

Increase Gas - Turn Counter Clockwise

IF FOR ANY REASON THE INPUT SCREW IS ADJUSTED, A "COMBUSTION ANALYZER"

MUST BE USED TO ENSURE SAFE AND PROPER OPERATION OF THE GAS VALVE.

Adjustments to the Throttle screw may only be made by a qualified gas technician, while

using a calibrated combustion analyzer capable of measuring CO

2

and CO. Failure to

follow these instructions may result in serious injury or death.

Adjustments to the Throttle screw may only be performed if the gas line pressure is

maintained above minimum levels throughout the duration of the test; see Table 9-1.

Failure to follow these instructions may result in serious injury or death.

Combustion Calibration - To calibrate burner operation, perform the following procedure using a calibrated

combustion analyzer capable of measuring CO

2

and CO from Natural and Propane Gas burning appliances:

1. Operate the unit at the maximum modulation rate, see Table 9-2.

2. Ensure the gas line pressure is maintained within tolerance, see Table 9-1.

3. While at the maximum modulation rate, measure the CO

2

and CO; adjust as necessary, using the Throttle

Screw, to be within the limits listed in Table 9-1.

4. Operate the unit at the minimum modulation rate (Table 9-2). Ensure the combustion remains smooth and

CO

2

and CO remain within the limits (Table 9-1). If not, do not adjust further, contact NTI for assistance.

Flue Gas Analysis and Adjustment

Each Trinity Lx is factory set to operate with Natural Gas, for boilers field converted to operate with Propane

Gas, a flue gas analysis and adjustment is mandatory. See Table 7-1 and propane conversion instructions.

Models Lx150-400 require the installation of an LP orifice prior to operating with

Propane Gas, see Propane conversion instructions for more details. To convert the

Lx500 to operate with Propane Gas requires field calibration of the throttle/input screw; see “Lx500

Adjustments” in Section 9.0 and Propane conversion instructions. Models Lx600-800 only operate with Natural

Gas; conversion to Propane is not an option. Failure to follow these instructions will result in property damage,

personal injury or death.

Failure to perform the flue gas analysis and adjustment detailed in this section may result

in erratic and unreliable burner operation, leading to reduced efficiency, increased fuel

consumption, reduced component life, heat exchanger combustion deposits, and general

unsafe operation. Failure to follow these instructions may result in serious injury or

death.

Analysis - Trinity Lx flue gas test ports are located in the flue outlet adapter assembly. Test port access is either

from inside the boiler cabinet (Lx150, Lx150E & Lx200; Figure 9-7) or from outside the boiler cabinet

(Lx300-800; Figures 9-8 through 9-10). Remove the test port plug, perform flue gas analysis, and adjust

throttle/input screw as required until CO

2

and CO levels are within acceptable limits, see Table 9-1 Line

Pressure and Combustion Parameters. Once flue gas sampling completed, re-install test port plug. For model

with a threaded plug, seal threads with Teflon tape before reinstalling plug.

Failure to re-install the test port plug will result in damage to the unit, property damage,

fire, explosion, serious injury or death.

Loading...

Loading...