95

TRX Series II - Installation - Startup - Maintenance Instructions

Part 11 - Start-Up

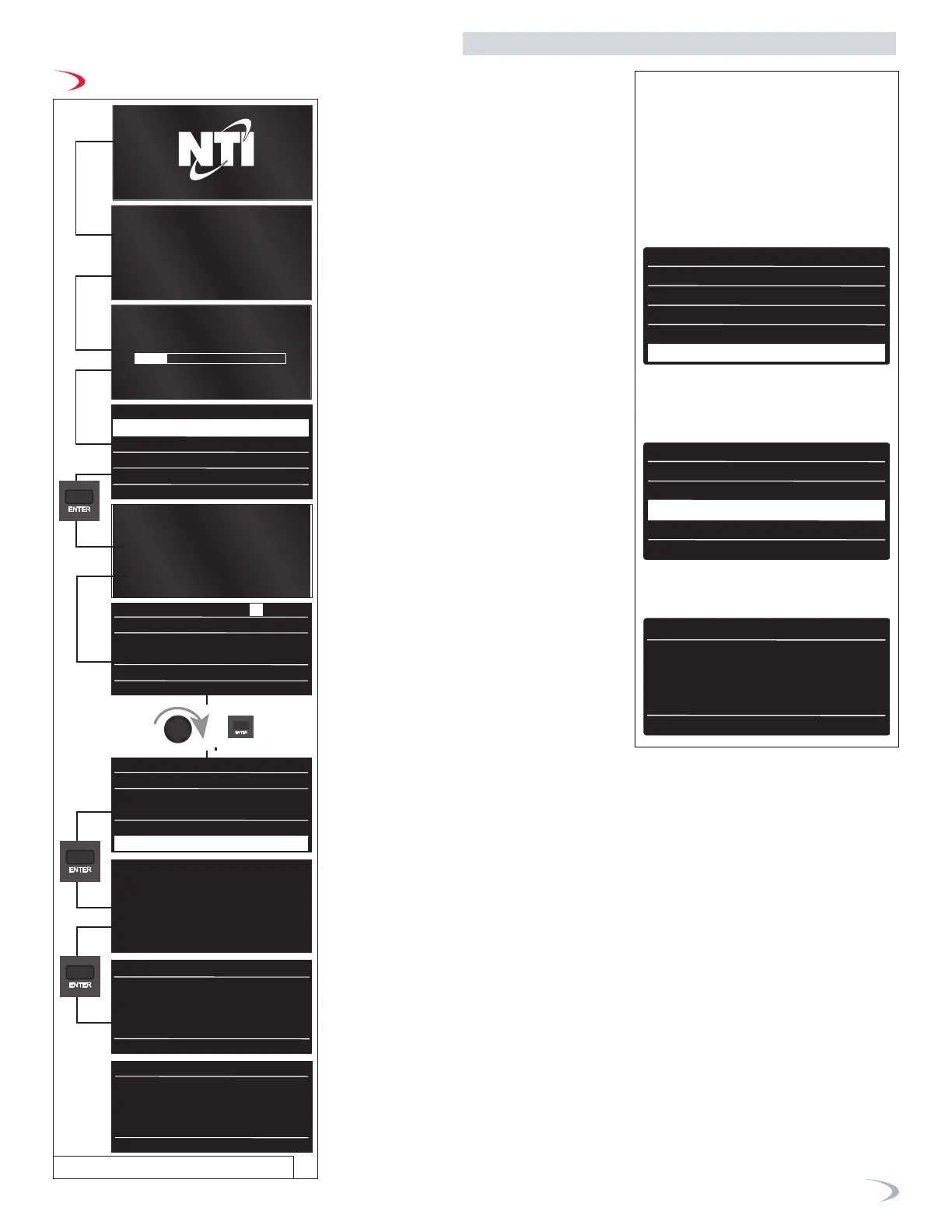

A. First Ignition

1. Make sure that the gas supply is valved

off and the boiler is properly connected

to a 120VAC power supply with

sufficient earth ground.

2. Unscrew the cap on any automatic air

vents located in the system piping.

3. Ensure that the system pressure is at

least 12 psi on the tridicator and no hot

water or heating requests will be made.

4. Turn the power supply to the boiler on.

The display lights up and activates the

initialization procedure:

5. The boiler requir to select/insert

language ans Time &Date.

6. The air purge function starts

automatically.

6. During the air purge cycle open the

manual air vent on the primary heat

exchanger. Close the air vent when clear

water free of air is visible.

8. Ensure the system is completely purged

of air after the purging cycle has ended.

If not, repeat the procedure.

SEE NOTE “AIR PURGE FUNCTION”

NOTE: It is recommended to run

through the full initial purge cycle at

install. Do not cut the purge cycle short.

9. Purge air from the CH and DHW

systems. After CH system purging is

complete, verify that system pressure is

at least 12 psi on the pressure gauge.

NOTE: The water pressure switch safety

is set at 8 psi to protect the boiler.

10. The exhaust vent piping for combustion

products should be suitable and free

from any obstructions.

11. Any necessary ventilation inlets in the

room should be open (power vent

installation).

12. Verify that the condensate drain hose

is connected to the outlet of the

boiler condensate trap, and that the

condensate trap is fully intact.

13. Set the room thermostat to the highest

setting to start the boiler and test

Lockout Error 501.

NOTE: The boiler will display a Lockout

Error 501 after the 3rd consecutive

failed ignition attempt.

- The combustion fan will pre-purge

for a short time before activating

the igniter.

- Ensure the combustion fan post-

purges for at least 5 seconds

before reactivating the igniter.

- After the boiler displays Error 501,

set the room thermostat to the

normal setting to start the boiler.

14. Open the gas supply to the boiler and

check all joints for leaks. Repair any

leaks before proceeding.

15. Press the RESET button to clear Error

501. The display will show OK.

16. Start the boiler by applying a central

heating and/or DHW demand.

Device discovery.......

00:01:00

Initializing.......

00:01:00

Device discovery.......

00:01:00

Initializing.......

00:01:00

Device discovery.......

00:01:00

Initializing.......

00:01:00

Figure 104 - Initialization procedure

American English

Francais

Espanol

Italiano

Language

Selected Language:

American english

English

Espanol

Francais

American english

Language

American English

Francais

Espanol

Italiano

Language

Selected Language:

American english

English

Espanol

Francais

American english

09/28/2023

Single Boiler

Status

Demand

Outlet:

Standby

158 °F 0 %

Power:

66°F

10:36

Date

Thursday

00 : 00

Time

Legal hour

Manual

each item

Thursday 09 / 28 / 2023

10 : 36

Legal hour automatic

09 / 28 / 2023

Date

Thursday

00 : 00

Time

Legal hour Manual

09 / 28 / 2023

+

Save

09/28/2023

Single Boiler

Status

Demand

Outlet:

Standby

158 °F 0 %

Power:

66°F

10:36

Date

Thursday

00 : 00

Time

Legal hour

Save

Manual

each item

Thursday 09 / 28 / 2023

10 : 36

Legal hour automatic

09 / 28 / 2023

Date

Thursday

00 : 00

Time

Legal hour Manual

09 / 28 / 2023

+

Save

09/28/2023

Single Boiler

Status

Demand

Outlet:

Standby

158 °F 0 %

Power:

66°F

10:36

Date

Thursday

00 : 00

Time

Legal hour

Save

Manual

each item

Thursday 09 / 28 / 2023

10 : 36

Legal hour automatic

09 / 28 / 2023

Date

Thursday

00 : 00

Time

Legal hour Manual

09 / 28 / 2023

+

Save

09/28/2023

Single Boiler

Status

Demand

Outlet:

Standby

158 °F 0 %

Power:

66°F

10:36

Date

Thursday

00 : 00

Time

Legal hour

Save

Manual

each item

Thursday 09 / 28 / 2023

10 : 36

Legal hour automatic

09 / 28 / 2023

Date

Thursday

00 : 00

Time

Legal hour Manual

09 / 28 / 2023

+

Save

09/28/2023

Single Boiler

Status

Demand

Outlet:

Inhibited

Air Purge Active

F.Signal 255

158 °F 0 %

Power:

66°F

10:36

09/28/2023

Single Boiler

Status

Demand

Outlet:

Standby

158 °F 0 %

Power:

66°F

10:36

Date

Thursday

00 : 00

Time

Legal hour

Save

Manual

each item

Thursday 09 / 28 / 2023

10 : 36

Legal hour automatic

09 / 28 / 2023

Date

Thursday

00 : 00

Time

Legal hour Manual

09 / 28 / 2023

+

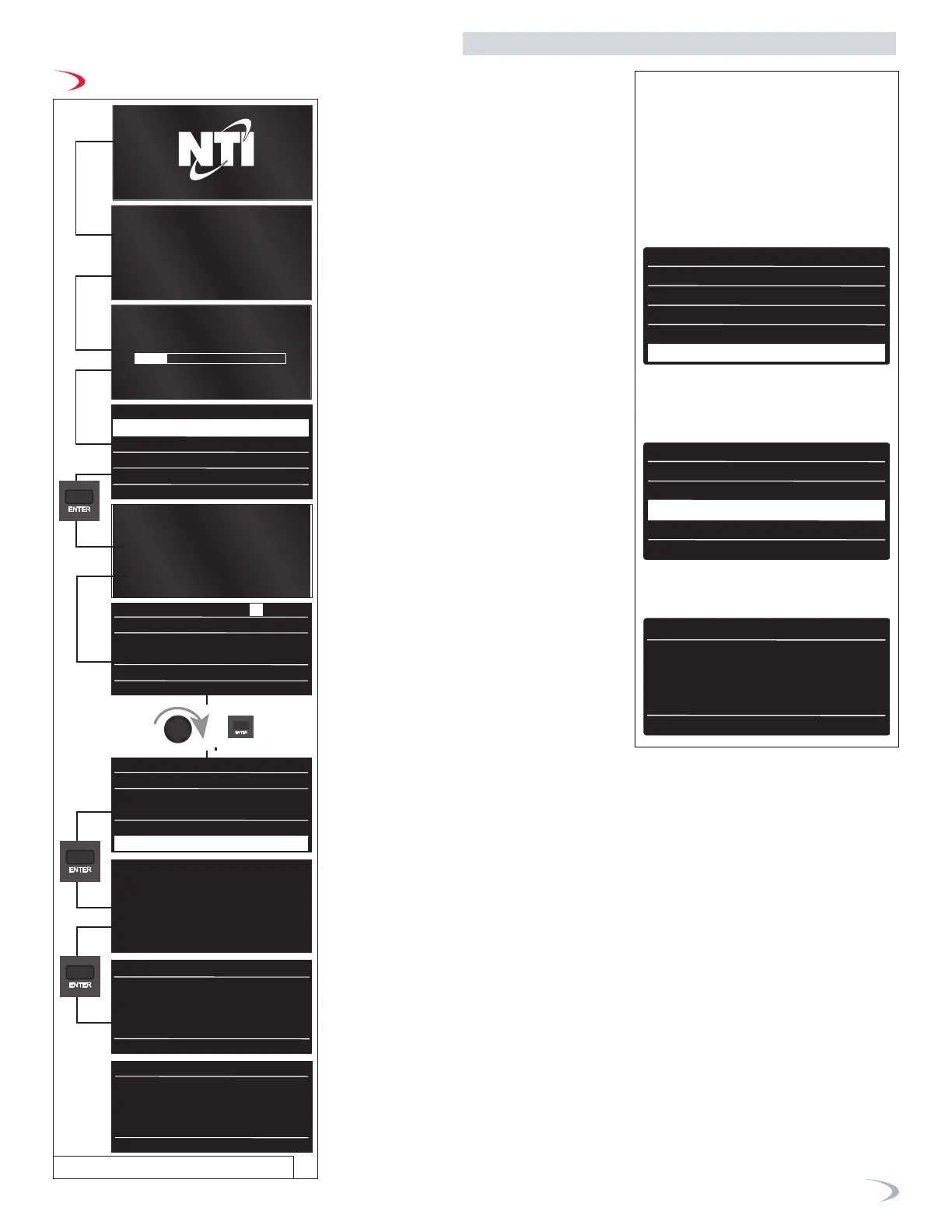

NOTE: AIR PURGE FUNCTION

To activate the Air purge Function

access to the Test Mode Menu.

Press the MENU button.

Turn the dial to select Test Mode and

press ENTER.

Insert the code 234

and press ENTER.

Turn the dial to select Air Purge

Functione and Press ENTER.

The boiler starts a Air Purge cycle.

Setup wizard

Boiler Details

User Menu

Tech menu

Test mode

Test Mode

Burner Test

Output Test

Air purge Function

Test Mode

Burner Test

Output Test

Air purge Function

Manual Mode Activation

OFF

Output Test

ON

Output Test

Manual Mode Activation OFF

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Output Test

Manual Mode Activation ON

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Test Mode

Burner Test

Output Test

Air purge Function

09/28/2023

Single Boiler

Status

Demand

Outlet:

Inhibited

Air Purge Active

F.Signal 255

158 °F 0 %

Power:

66°F

10:36

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Min Power Test in Progress

Max Power

F.Signal 125

95 °F

10 %

Power:

66°F

10:36

Min Power

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Max Power Test in Progress

F.Signal 255

158 °F

100 %

Power:

66°F

10:36

Min Power Max Power

Technical Area

Setup wizard

Boiler Details

User Menu

Tech menu

Test mode

Test Mode

Burner Test

Output Test

Air purge Function

Test Mode

Burner Test

Output Test

Air purge Function

Manual Mode Activation

OFF

Output Test

ON

Output Test

Manual Mode Activation OFF

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Output Test

Manual Mode Activation ON

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Test Mode

Burner Test

Output Test

Air purge Function

09/28/2023

Single Boiler

Status

Demand

Outlet:

Inhibited

Air Purge Active

F.Signal 255

158 °F 0 %

Power:

66°F

10:36

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Min Power Test in Progress

Max Power

F.Signal 125

95 °F

10 %

Power:

66°F

10:36

Min Power

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Max Power Test in Progress

F.Signal 255

158 °F

100 %

Power:

66°F

10:36

Min Power Max Power

Technical Area

Setup wizard

Boiler Details

User Menu

Tech menu

Test mode

Test Mode

Burner Test

Output Test

Air purge Function

Test Mode

Burner Test

Output Test

Air purge Function

Manual Mode Activation

OFF

Output Test

ON

Output Test

Manual Mode Activation OFF

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Output Test

Manual Mode Activation ON

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Test Mode

Burner Test

Output Test

Air purge Function

09/28/2023

Single Boiler

Status

Demand

Outlet:

Inhibited

Air Purge Active

F.Signal 255

158 °F 0 %

Power:

66°F

10:36

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Min Power Test in Progress

Max Power

F.Signal 125

95 °F

10 %

Power:

66°F

10:36

Min Power

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Max Power Test in Progress

F.Signal 255

158 °F

100 %

Power:

66°F

10:36

Min Power Max Power

17. THE BOILER IS LIMITED TO A

MAXIMUM POWER LEVEL OF 50%

FOR THE FIRST 5-MINUTES OF

BURNER OPERATION.

18. PROCEED WITH THE

“COMBUSTION CHECKING

PROCEDURE.”

Loading...

Loading...