97

TRX Series II - Installation - Startup - Maintenance Instructions

Part 11 - Start-Up

Make sure the calibrated combustion analyzer is set to the

appropriate gas type. Failure to do so could result in serious

personal injury or death.

It is required to use a calibrated combustion analyzer to verify

final adjustment according to the combustion chart (Table 43).

Failure to do so could result in serious personal injury or death.

It is very important that the combustion settings are within the

ranges listed in Table 43. Visually looking at the burner does not

determine combustion quality. Failure to measure combustion

with a calibrated combustion analyzer and set the throttle within

the recommended combustion measurements could result in

property damage, severe personal injury, or death.

WARNING

Note: BURNER TEST

To activate the BURNER TEST access to the Test Mode Menu.

Press the MENU button.

Turn the dial to

select Test Mode

and press ENTER.

Turn the dial to

select Burner Test

and press ENTER.

Turn the dial to

select MAX Power

and press ENTER.

The boiler turns on

and ramps to Max

Power (100%).

Set combustion

according to Table

43.

Turn the dial to

select MIN Power

and press ENTER.

The boiler

modulates to Min

Power (10%).

Set combustion

according to Table

43. Press ESC to stop the test.

Technical Area

Setup wizard

Boiler Details

User Menu

Tech menu

Test mode

Test Mode

Burner Test

Output Test

Air purge Function

Test Mode

Burner Test

Output Test

Air purge Function

Manual Mode Activation

OFF

Output Test

ON

Output Test

Manual Mode Activation OFF

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Output Test

Manual Mode Activation ON

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Test Mode

Burner Test

Output Test

Air purge Function

09/28/2023

Single Boiler

Status

Demand

Outlet:

Inhibited

Air Purge Active

F.Signal 255

158 °F 0 %

Power:

66°F

10:36

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Min Power Test in Progress

Max Power

F.Signal 125

95 °F

10 %

Power:

66°F

10:36

Min Power

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Max Power Test in Progress

F.Signal 255

158 °F

100 %

Power:

66°F

10:36

Min Power Max Power

Technical Area

Setup wizard

Boiler Details

User Menu

Tech menu

Test mode

Test Mode

Burner Test

Output Test

Air purge Function

Test Mode

Burner Test

Output Test

Air purge Function

Manual Mode Activation

OFF

Output Test

ON

Output Test

Manual Mode Activation OFF

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Output Test

Manual Mode Activation ON

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Test Mode

Burner Test

Output Test

Air purge Function

09/28/2023

Single Boiler

Status

Demand

Outlet:

Inhibited

Air Purge Active

F.Signal 255

158 °F 0 %

Power:

66°F

10:36

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Min Power Test in Progress

Max Power

F.Signal 125

95 °F

10 %

Power:

66°F

10:36

Min Power

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Max Power Test in Progress

F.Signal 255

158 °F

100 %

Power:

66°F

10:36

Min Power Max Power

Technical Area

Setup wizard

Boiler Details

User Menu

Tech menu

Test mode

Test Mode

Burner Test

Output Test

Air purge Function

Test Mode

Burner Test

Output Test

Air purge Function

Manual Mode Activation

OFF

Output Test

ON

Output Test

Manual Mode Activation OFF

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Output Test

Manual Mode Activation ON

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Test Mode

Burner Test

Output Test

Air purge Function

09/28/2023

Single Boiler

Status

Demand

Outlet:

Inhibited

Air Purge Active

F.Signal 255

158 °F 0 %

Power:

66°F

10:36

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Min Power Test in Progress

Max Power

F.Signal 125

95 °F

10 %

Power:

66°F

10:36

Min Power

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Max Power Test in Progress

F.Signal 255

158 °F

100 %

Power:

66°F

10:36

Min Power Max Power

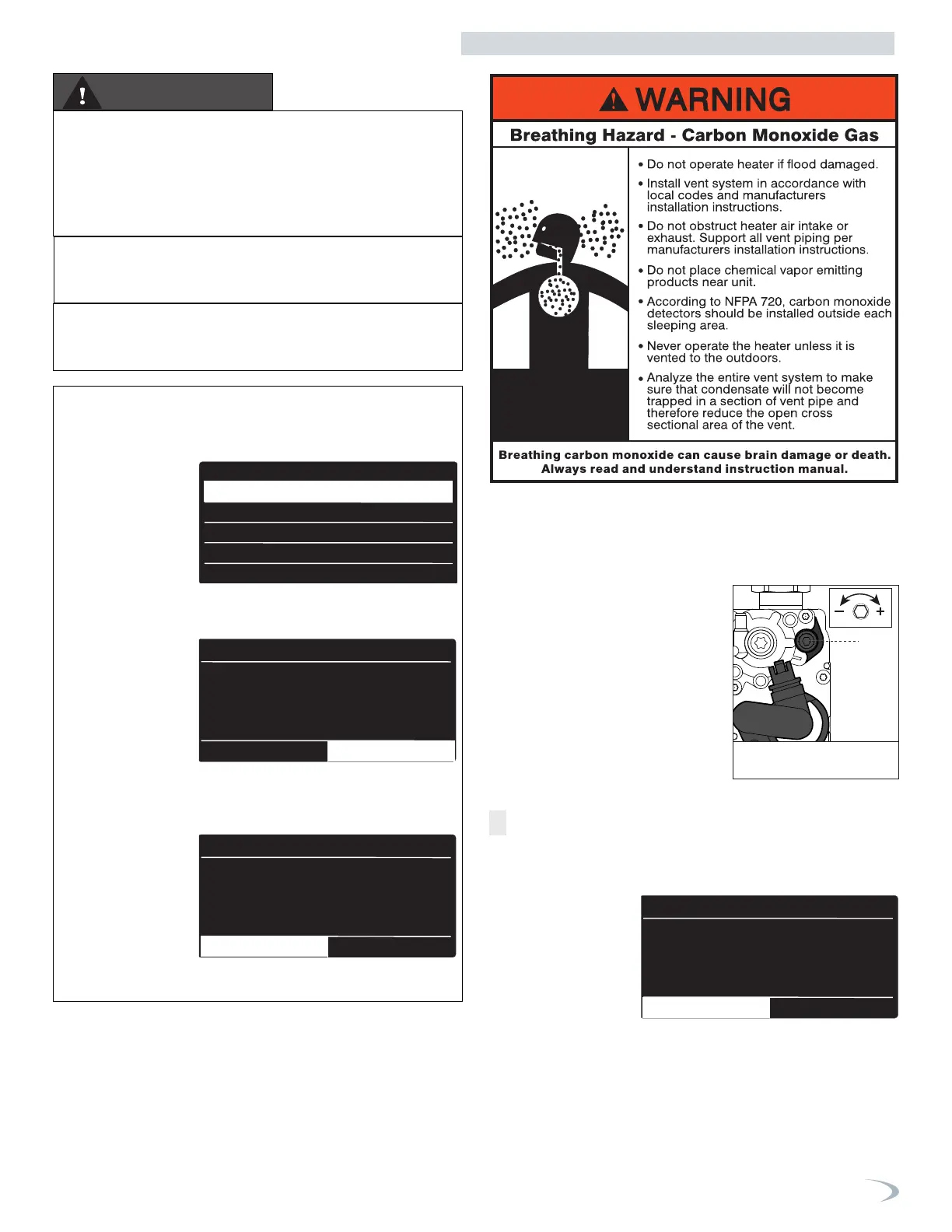

Adjusting the Gas Valve at Max Power (100%)

Adjust the gas valve by turning setting screw 4 clockwise to increase

the CO2 level; counterclockwise to reduce the CO2 level (1 turn

adjusts the CO2 level by approximately 0.3%). Wait 1 minute after

each change in setting for the CO2

value to stabilize.

If the value measured corresponds to

the value given in the Table 43, max

adjustment is complete. Otherwise

continue the setting procedure.

ATTENTION!! The Test Function

will automatically deactivate after

30 minutes, or Test Function can be

turned off manually by pressing the

RESET button.

OPERATION 4

CHECKING THE CO2 AT MIN POWER (10%)

From the Burner Test screen, turn the dial to select MIN POWER and

press ENTER to operate the boiler at minimum power.

Wait 1 minute for

the boiler to stabilize

before carrying out the

combustion analyses.

If the CO2 (%) reading

at Min Power is outside

the range indicated

in Table 43, adjust the

gas valve following

the instructions below.

Otherwise proceed directly to OPERATION 5.

NOTE: Min Power calibration must be performed after Max Power

calibration.

NOTE: The CO2 at Min Power (10%) must not be set higher than the

CO2 reading at Max Power (100%); it may be set lower by as much as

0.3%

4

Figure 107 - Max Power

CO2 Adjustment

Technical Area

Setup wizard

Boiler Details

User Menu

Tech menu

Test mode

Test Mode

Burner Test

Output Test

Air purge Function

Test Mode

Burner Test

Output Test

Air purge Function

Manual Mode Activation

OFF

Output Test

ON

Output Test

Manual Mode Activation OFF

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Output Test

Manual Mode Activation ON

OFF

OFF

OFF

OFF

Pump Test

Fan Test

3 way valve Test

DHW Pump Test

Test Mode

Burner Test

Output Test

Air purge Function

09/28/2023

Single Boiler

Status

Demand

Outlet:

Inhibited

Air Purge Active

F.Signal 255

158 °F 0 %

Power:

66°F

10:36

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Min Power Test in Progress

Max Power

F.Signal 125

95 °F

10 %

Power:

66°F

10:36

Min Power

09/28/2023

Single Boiler

Status

Demand

Outlet:

Run

Max Power Test in Progress

F.Signal 255

158 °F

100 %

Power:

66°F

10:36

Min Power Max Power

Loading...

Loading...