22

PROGRAM Vip Esse Model

S

he machine is switched on by the main

witch (Figs. 1-2, no. 6), and the machine

nctioning state is shown by the pilot light

n the keyboard. At the same time, the cup

armer is started automatically, in order to

stablish the internal pressure of the boiler.

lease Note: this function avoids unpleasant

ow back into the boiler from the steam

be, caused by depressions created in the

oiler itself when the machine is switched

ff. For this reason, if the system is to func -

on correctly, it is necessary to wait until the

up warmer switches off automatically (after

pprox. 15 min.), and therefore, the machi -

e must not be operated manually.

nhook the filter holder from the unit and fill

ith one or two measures of ground coffee,

ccording to the filter being used. Use the

ress supplied to push down the coffee and

emove any residues from around the edge

f the filter (this guarantees a better gasket

rip, as well as less wear). Insert the filter

y pressing the button for the dose of cof-

e desired, the pump and solenoid valve

ill be activated and the coffee will be deli-

ered. This operation is indicated by the

ghting up of the relative led. Press STOP

lease Note: During pauses, leave the filter

older inside the unit, so that it remains

arm. The delivery units have a temperature

alance function that runs using a hot water

irculation system, in order to guarantee

aximum thermal endurance during use.

he hot water solenoid valve is activated and

elivery is started by pressing the correct

button. This operation is indicated by the

lighting up of the relative led. When delivery

time is equal to the set value, the system

itself will close the solenoid. Hot water can

be delivered at the same time as coff e e .

Please Note: The “Program Vip Esse” model

is equipped with a hot water mixer that ena -

bles temperature regulation of the water

being released and to maximise the perfor -

mance of the system. The mixer is adjusted

by first removing the left hand panel of the

machine and turning the register knob.

Tightening this knob will increase tempera -

ture (Fig. 10).

Switching on the Cup Warmer

The cup warmer is switched on using the

relative key on the control panel. The cup

warmer is switched off by pressing stop.

General Cleaning Standards

To preserve the machine characteristics over

time, it should be kept scrupulously clean.

All chrome-plated and steel parts, including

the steam and hot water tubes, should be

cleaned with a damp cloth. Once a week,

the stainless steel sprinklers should be

disassembled, cleaned and checked to

ensure that the perforations are not blocked

in any way. To carry out this operation, use

a screwdriver to loosen the central screw of

the sprinkler.

Cleaning the Unit With the Blind Filter

After replacing the filter with the blind one

supplied, insert two teaspoons of special-

purpose detergent powder and place the fil-

ter holder inside the unit. Press one of the

c o ffee keys and stop after 10 seconds.

Repeat the operation several times, then

remove the filter holder and effect some deli-

veries to eliminate any detergent residues.

Cleaning the Filters and Filter Holders

Mix two teaspoons of special-purpose

detergent in half a litre of hot water and

soak both the filter and filter holder (not the

handle), for half an hour. Next, rinse under

plenty of running water.

Recharging

To avoid the formation of lime scale depo-

sits inside the boiler and heat exchangers,

the water softener must be kept in perfect

working order. For this reason, the ionic

resins must be recharged on a regular

basis.

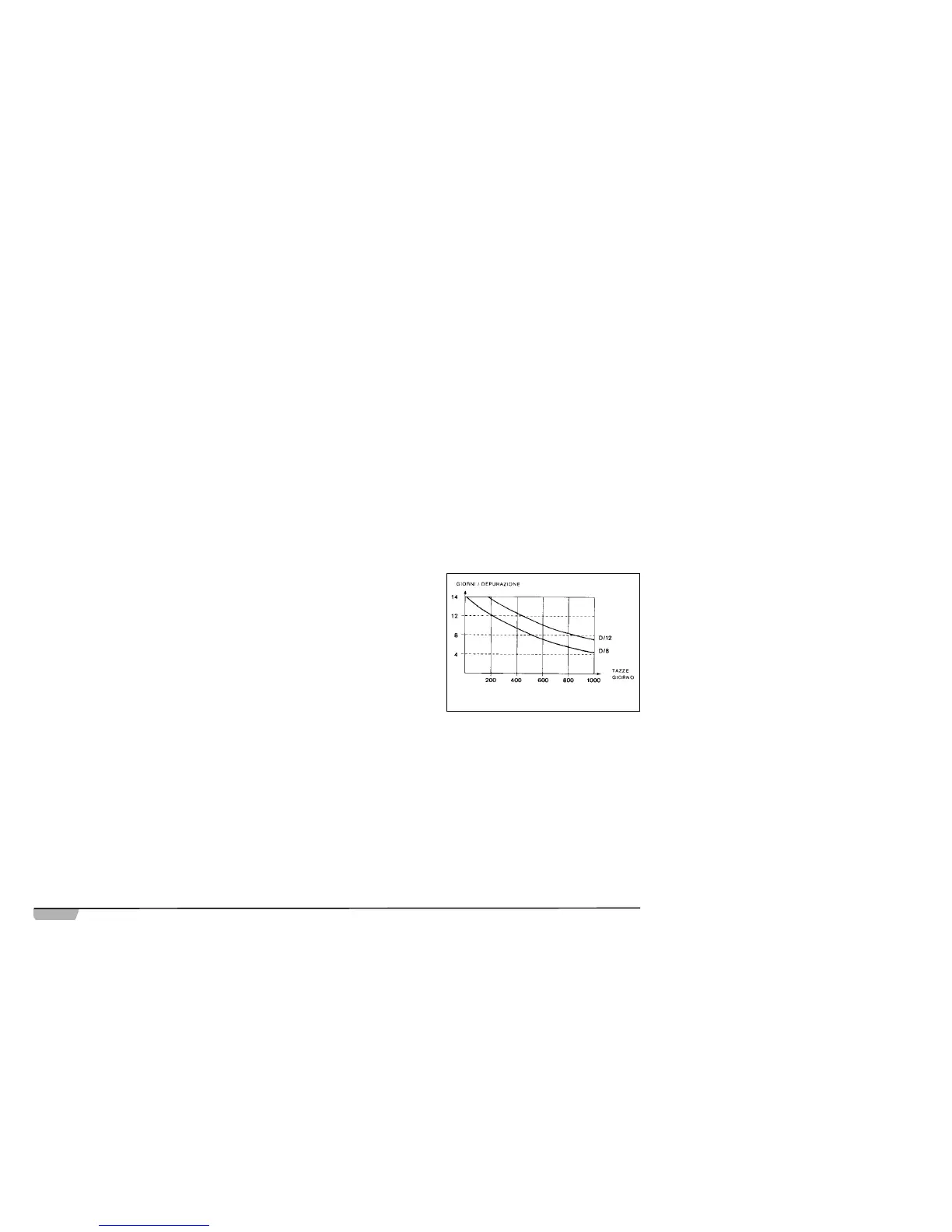

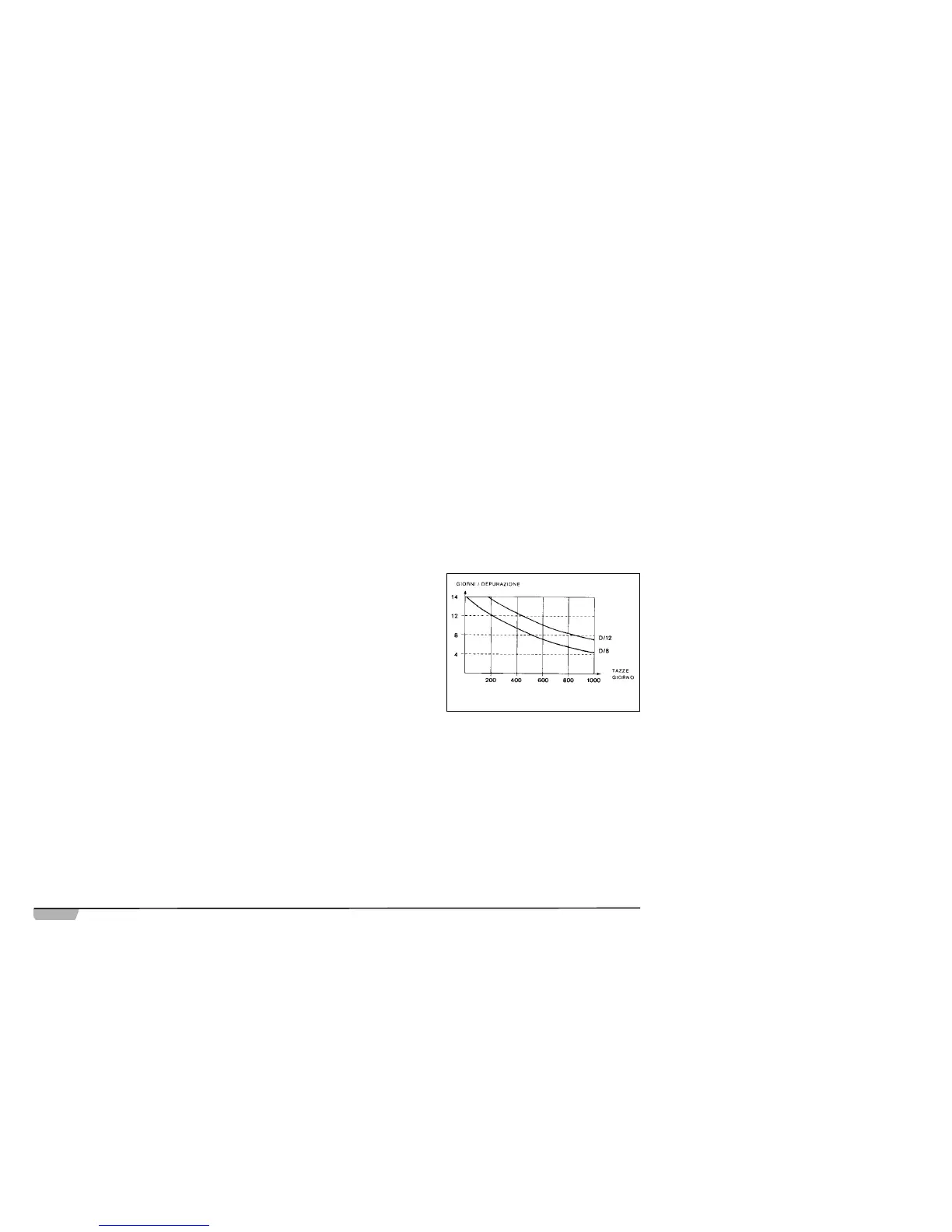

Recharging times must be established

according to the quantity of coffee delivered

during a day and to water hardness.

Indications have been given in the diagram

shown in Fig. 11.

A) switch off the machine and place a contai-

ner with a capacity of at least 5 litres

underneath the tube E (Fig. 12-A). Tu r n

the levers C and D from left to right (Fig.

12-B), remove the plug by unscrewing the

knob G and pour in a kilo of cooking salt.

B) Replace the plug and turn the lever C

back to the left (Fig. 12-C), leaving the

salt water to run out of the tube F until it

returns fresh (approx. 1/2 hour).

C) Then turn the lever D back to the left

(Fig. 12-D).

Figure 11

Loading...

Loading...