INSTALLATION, USE & CARE INSTRUCTIONS

INSTALLATION

5

For ADA compliance installation guidelines, please type the model number into our website.

RECOMMENDED TOOLS AND ACCESSORIES

• Measuring tape

• Phillips screwdriver no. 2

• Nut driver or socket 3/8”

• Flat blade screwdriver (to open knockout holes)

• Saw (to cut holes in cabinet)

• Sheet metal shears

• Pliers

• Metal foil duct tape

• Scissors (to cut metal foil duct tape)

• Pencil

• Wire stripper

• 2 Appropriate wire nuts

• Strain relief, 7/8” diameter (to secure house wiring

cable to the hood)

CONTENTS

Before proceeding to the installation, check the contents of the box. If items are missing or damaged, contact the

manufacturer.

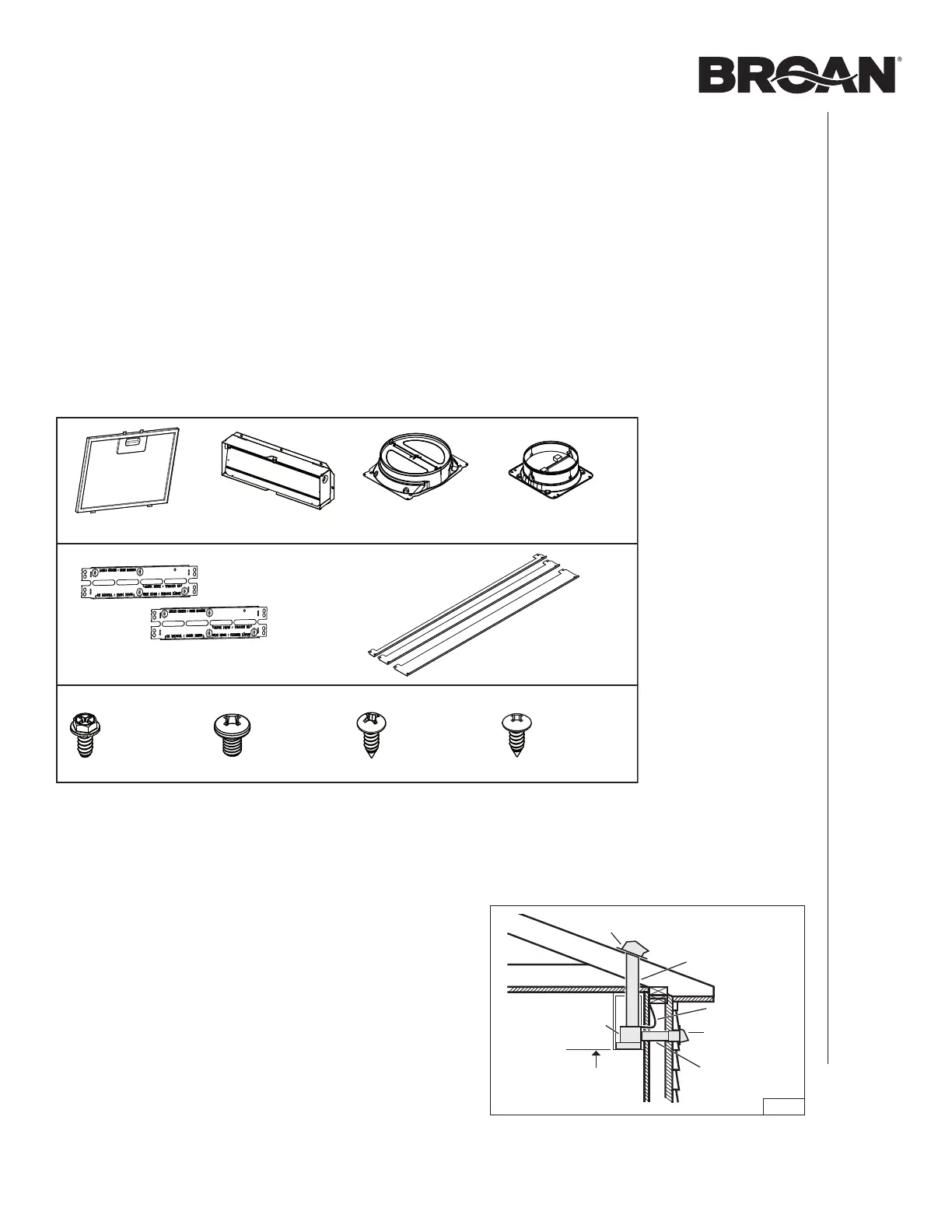

Make sure that the following items are included:

(1) PARTS BAG* CONTAINING:

(4) NO. 8-18 X 1/4”

M

ETAL SCREWS

* FIND PA RT S BAG BEHIND THE ELECTRICAL COMPARTMENT COVER

(1) SET OF 3 FILLERS

(1) 3¼” X 10”

DAMPER ASSEMBLY

(ATTACHED TO THE BACK OF THE UNIT)

(1) 8” ROUND

DAMPER ASSEMBLY

(1) 6” ROUND

DAMPER ASSEMBLY

(ATTACHED TO ONE SIDE OF THE UNIT)

C

ABINET BRACKETS

(ATTACHED TO THE BACK OF THE UNIT)

(8) NO. 8-15 X 5/8”

P

AN HEAD

WOOD SCREWS

(4) NO. 6-18 X 5/8”

T

RUSS HEAD

WOOD SCREWS

(4) NO. 8-32 X 1/4”

M

ACHINE SCREWS

(2) GREASE FILTERS

24" MIN - 30" MAX

ABOVE

COOKING SURFACE

POWERPACK

INSERT

WALL CAP

ROOF CAP

8" OR 6" ROUND DUCT

OR

3¼" X 10" DUCT

HOUSE WIRING

3¼" X 10" DUCT

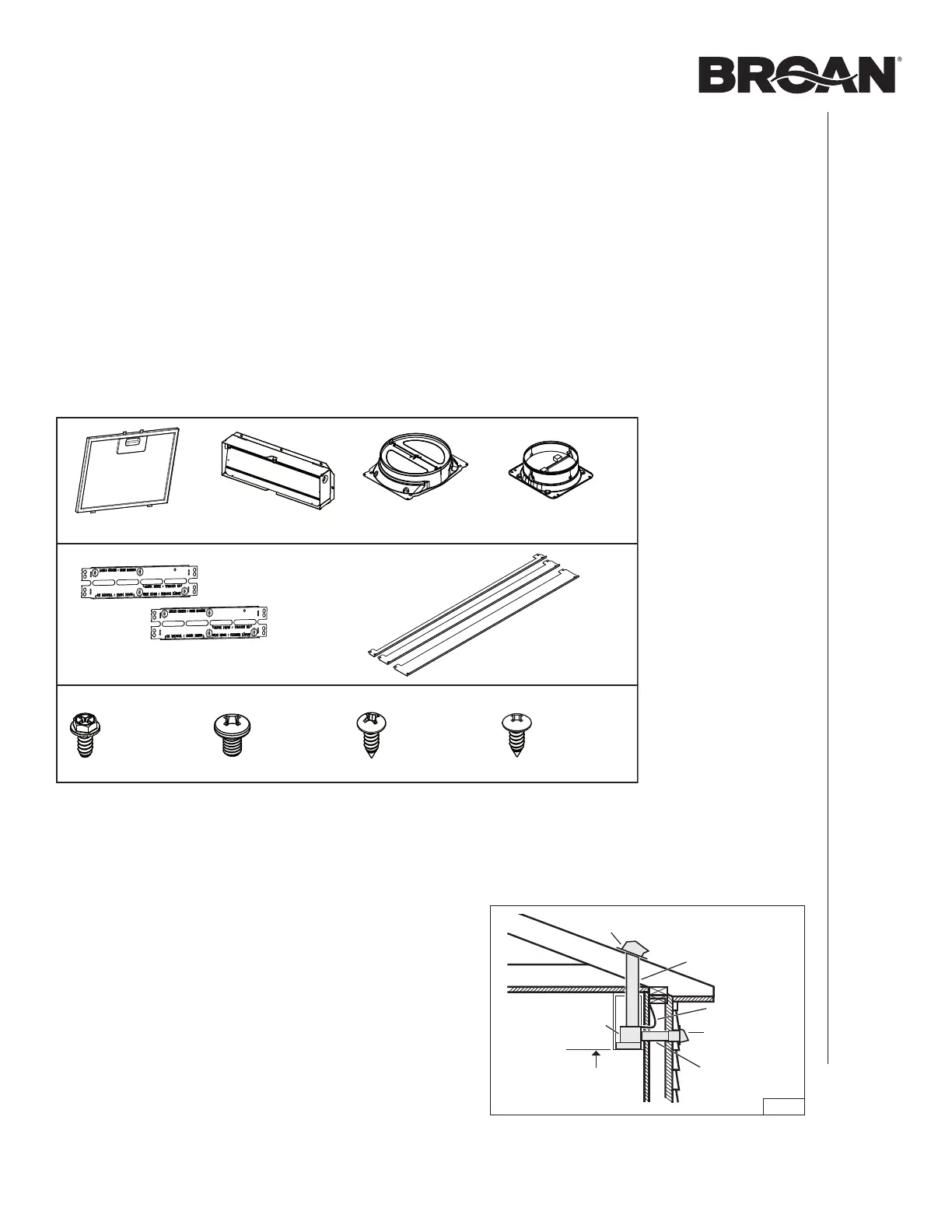

FIG. 1

INSTALL THE DUCTWORK

(DUCTED INSTALLATION ONLY)

NOTE: To reduce the risk of fire, use only metal ductwork.

1. Decide where the ductwork will run between the insert and

the outside. (FIG. 1)

2. A straight, short duct run will allow the hood to perform

most efficiently.

3. Long duct runs, elbows, and transitions will reduce the

performance of the hood. Use as few of them as possible.

Larger ducting may be required for best performance with

longer duct runs.

4. Install wall cap or roof cap (sold separately). Connect metal

ductwork to cap and work back towards the hood location. Use

2” metal foil duct tape to seal the joints between ductwork

sections.

Loading...

Loading...