OMC-160-3 Manual Page 16

6.4 Opening and closing the anemometer

The Observator OMC-160 anemometer is designed for low maintenance. The construction is entirely

made of non-corrosive materials and all components are conservatively rated.

The only components that are likely to require replacement due to normal wear are the precision ball

bearings. The OMC-160 anemometer must be opened to replace the bearings.

The OMC-160 anemometer should only be opened or disassembled in a clean workshop

The OMC-160 anemometer should only be opened or disassembled by a qualified

mechanical engineer

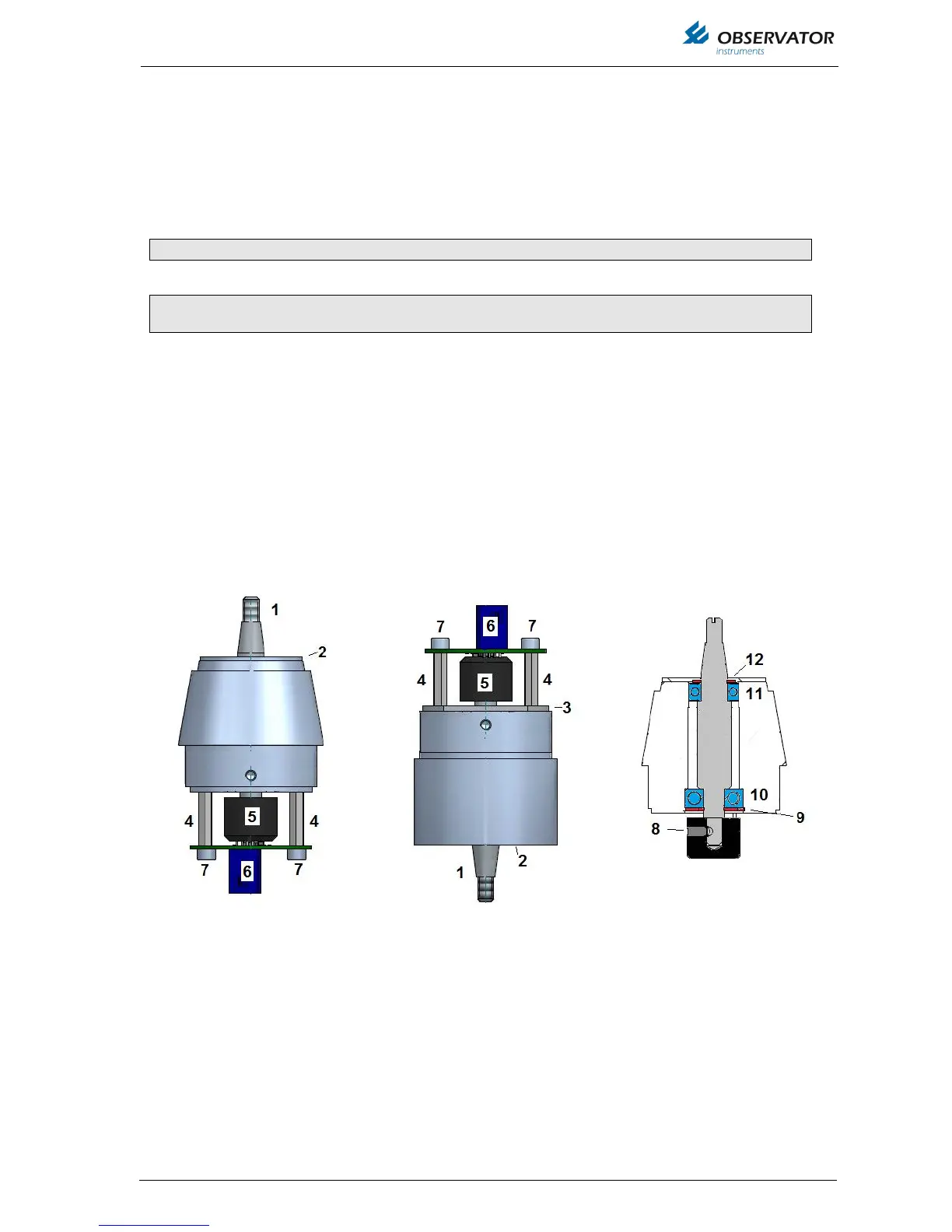

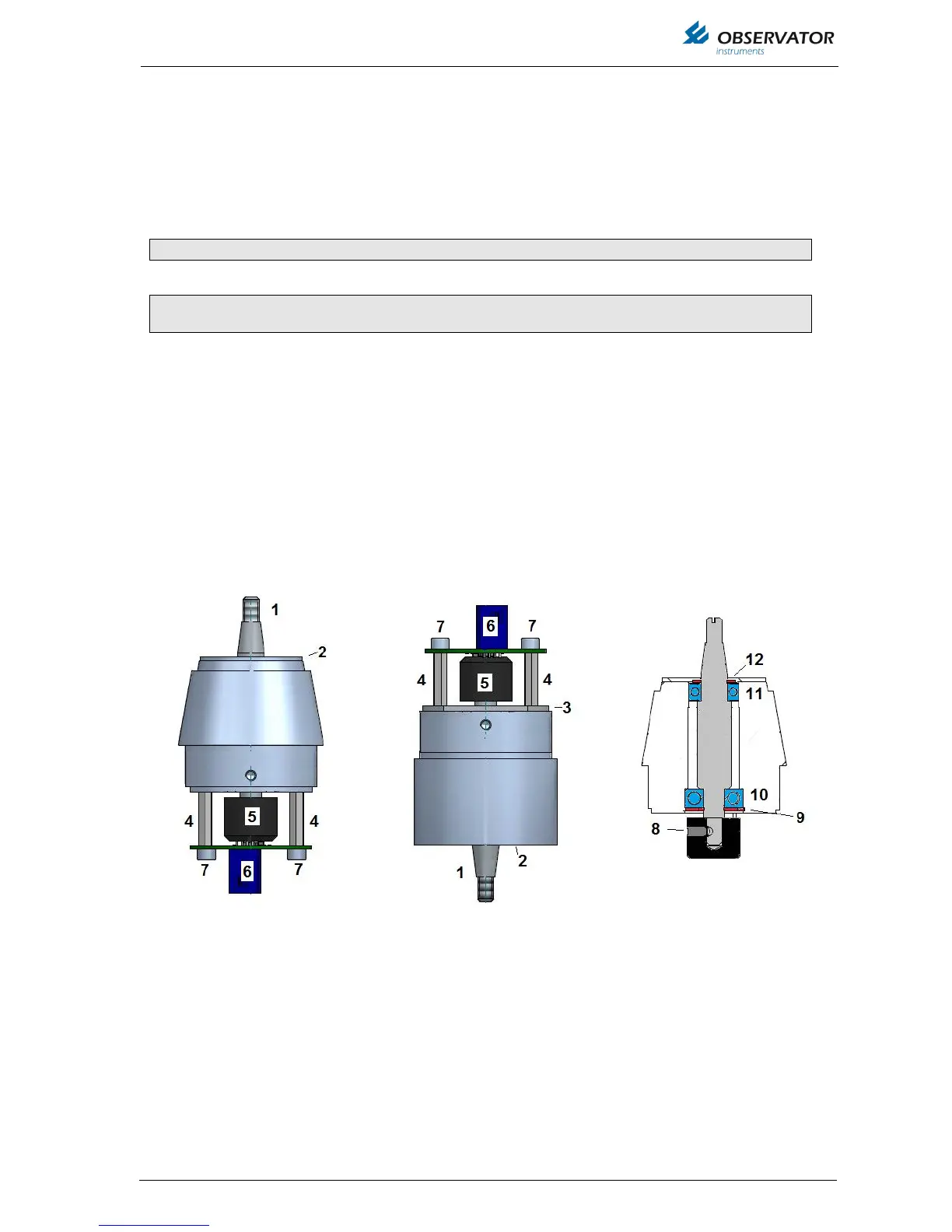

Refer to the assembly drawings of the anemometer for part names and locations.

First remove the cup unit or vane unit from their body by unscrewing the capped nut and lifting the unit.

Unscrew the bearing housing (2) or (3)

6.5 Replacement of ball bearings and sensor PCB’s

First, open the sensor housing as described in section 0

To gain access to the bearings remove the bearing cover-plate. The bearings can now be taken out

complete with the shaft.

Direction head assembly Speed head assembly Shaft –bearing assembly

(identical* for both heads)

1. Shaft 8. Hex screw

2. Bearing cover end plate 9. Circlip large*

3. Bearing cover (speed) plate** 10. Bearing large

4. Columns 11. Bearing small

5. Sensor element 12. Circlip small

6. Sensor PCB / Connector 13. Connector Cable assembly

7. Hex bolts 14. Ground wire

* Circlip (9) only present when no bearing cover (4) is fitted

** Bearing cover plate is replaced by Circlip 9 in some speed heads and all direction heads.

Loading...

Loading...