REGULATORS

DELTA 4 SECOND STAGE

© 2002 Design, 2005

PG-4

OCEANIC® Product Service Guide

Doc. 12-2803-r02 (10/3/10)

Fig. 1

DISASSEMBLY PROCEDURE

NOTE: Be sure to perform the steps outlined in the Initial

Inspection Procedures (Doc. 12-2202) prior to disassembling

the Regulator. Review the Troubleshooting Section to gain

a better idea of which internal parts may be worn, and to

better advise your customer of the service that is needed.

1. Snip the plastic TIE WRAP (8) that holds the MOUTHPIECE (9),

and remove the MOUTHPIECE. Inspect the condition of the

MOUTHPIECE to ensure that it is supple and free of any tears

or corrosion. Discard if found.

NOTE: For Swivel Versions 1 & 2 use step 2S. For Non-

Swivel Versions use Step 2N. For Version identication see

the Exploded-View Diagram.

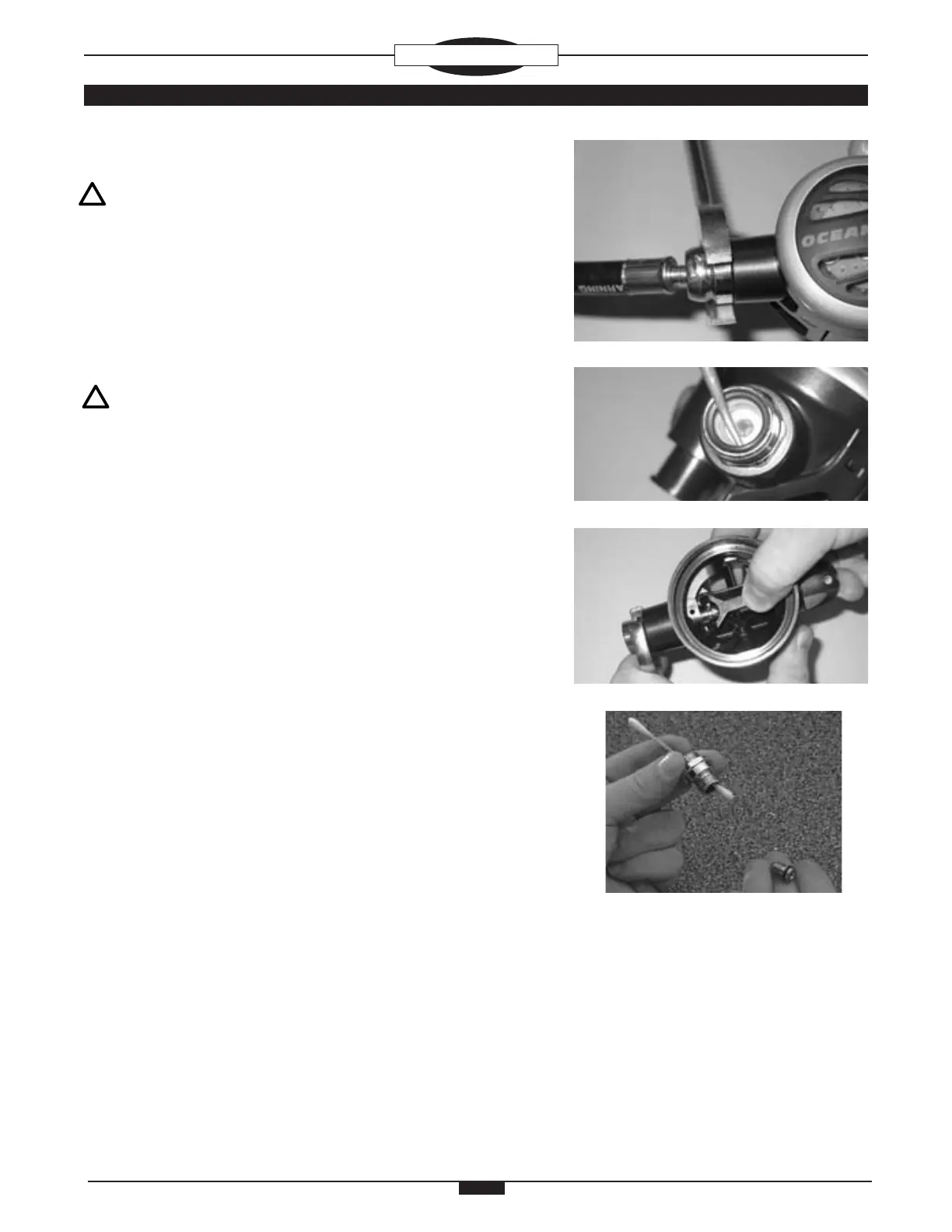

2S. Pull the Hose Protector back and remove the LP HOSE (38) from

the Second Stage by turning it counter clockwise using a 15/16"

open end wrench, while holding the HOUSING (5) secure (Fig.

1). Remove the LP HOSE O-RING (40) and LP HOSE WASHER

(39 ONLY USED on Swivel Version 1) (Fig. 2). Discard both

and DO NOT attempt to reuse them.

2N. Pull the Hose Protector back and remove the LP HOSE (45) from

the Second Stage by turning it counter clockwise using a 9/16"

open end wrench, while holding the HOUSING (5) secure.

3. Remove the COVER RING (1), using a Front Cover Tool if neces-

sary, and remove the FRONT COVER (2) and INNER FRONT

COVER (3) to expose the DIAPHRAGM (4).

4. Grasp the DIAPHRAGM (4) by the raised edges of the center,

and lift with a slight upward twist to remove it. Inspect the DIA-

PHRAGM to ensure it is supple and free of any tears, corrosion,

or other distortion. Discard if found.

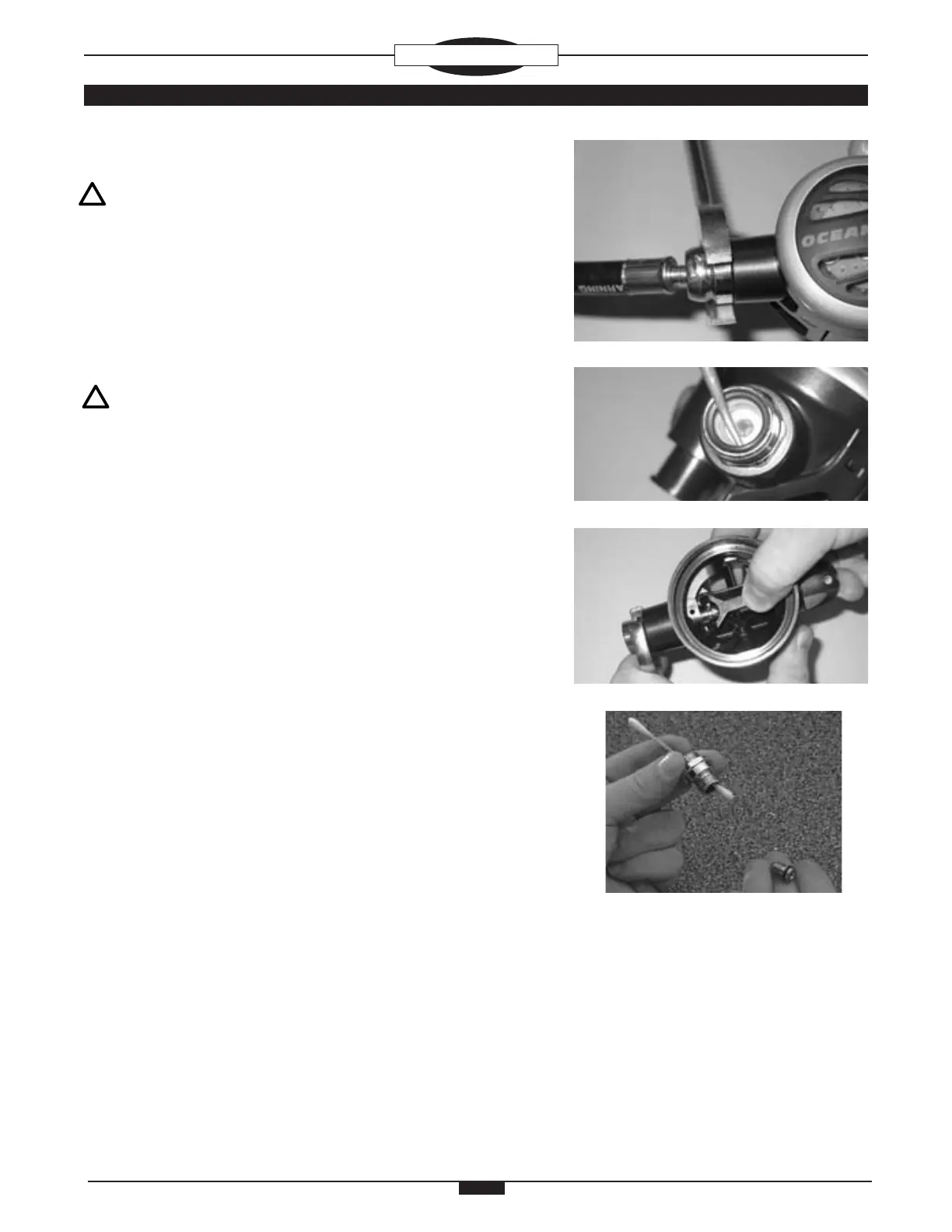

5. Depress and hold the LEVER ARM (17) to remove the SWIVEL

COUPLING (12) in a counter clockwise direction, using a 3/4"

open end wrench (Fig. 3).

6. Remove the COUPLING O-RING (13) from the SWIVEL COU-

PLING (12) and inspect for any signs of decay. Discard if found.

7. Using a narrow slotted blade screwdriver, remove the ORIFICE

(11) by turning it counter clockwise inside the SWIVEL COUPLING

(12). When it has disengaged completely from the Threads, press

it out with the use of a cotton swab (Fig. 4). Use caution to avoid

nicking or scratching the delicate Knife Edge of the ORIFICE as

this is done. Remove and discard the ORIFICE O-RING (10).

Inspect the ORIFICE carefully with the use of a magnier to

ensure that it is perfectly free of any scoring or nicks. If found,

discard and DO NOT attempt to reuse.

Fig. 3

Fig. 2

Fig. 4

Loading...

Loading...