Head Drive Time

The head drive time is modified to compensate for the amount of the voltage drop of the

POWLEV signal. By monitoring the voltage drop every 500 microseconds, the MPU is able to

control and maintain the impact necessary for each printhead pin.

Print Speed

Actual Voltage (+40 vdc) Passes Required Relative Print Speed

+34 vdc or greater 1 100%

+32 vdc to +34 vdc 1 Approximately 85%

+30 vdc to +32 vdc 1 Approximately 50%

+30 vdc or less 2 Less than 50%

Head Overheat Alarm Processing

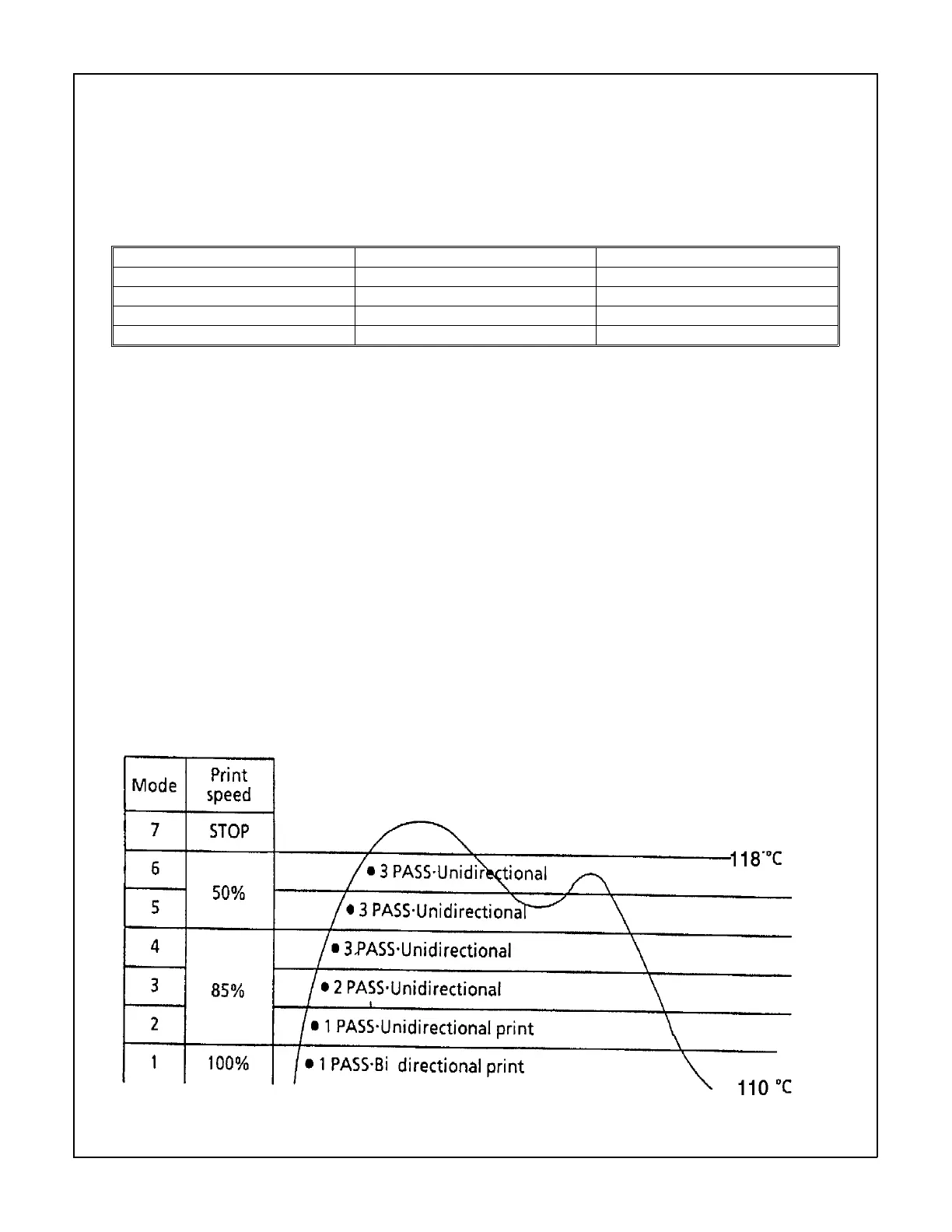

If the printhead temperature exceeds 110 degrees Celsius, the printer will switch to

uni-directional print. If the temperature exceeds 118 degrees Celsius, printing will stop. Once

the printhead cools, printing will resume.

Two thermistors are used to monitor the printhead temperature. One is contained in the

printhead. The other is in the printhead driver.

A thermistor in the printhead prevents over-heating of the coil during periods of continuous

bi-directional printing. If the temperature of the coil exceeds the pre-determined limits, the

control circuit detects the thermistor signal (TSD).

Another thermistor monitors the temperature of the printhead driver. If the temperature of the

driver exceeds the pre-determined limits, the control circuit detects the thermistor signal (TSD).

The voltage of the TSD signal is monitored at the MPU A/D port to control the pass number and

print method (uni-directional / bi-directional) at each of seven levels.

2-1-07c.tif

Microline 520/521 Service Handbook 2 - 15 Principles of Operation

P/N 59257803

Loading...

Loading...