61

14.5.4 Tower fails to depressurise

Description:

During normal operation there is a 4 min interval of purge air release when the tower

depressurizes in every-half cycle. During a half-cycle there is no regeneration/purge flow

interval on one or both towers.

Possible causes, inspection and fixing procedure:

1. No power supply, controller is OFF: Connect the power supply.

2. Dryer is in a STAND-BY MODE: Inspect the source of the STAND-BY signal.

3. Faulty control purge release valve: Inspect the control valve coils. If one or more the

coils keeps warming up considerably compared to other coils then the coil is

malfunctioning and could be causing the failure to open the purge release valve

during the regeneration/purge interval. Order the control valves service kit. For more

information see 14.2 Control Valves.

4. Clogged nozzle: Inspect the nozzle. If it is clogged, clean it! For more information see

13.5 Replacement of the nozzles.

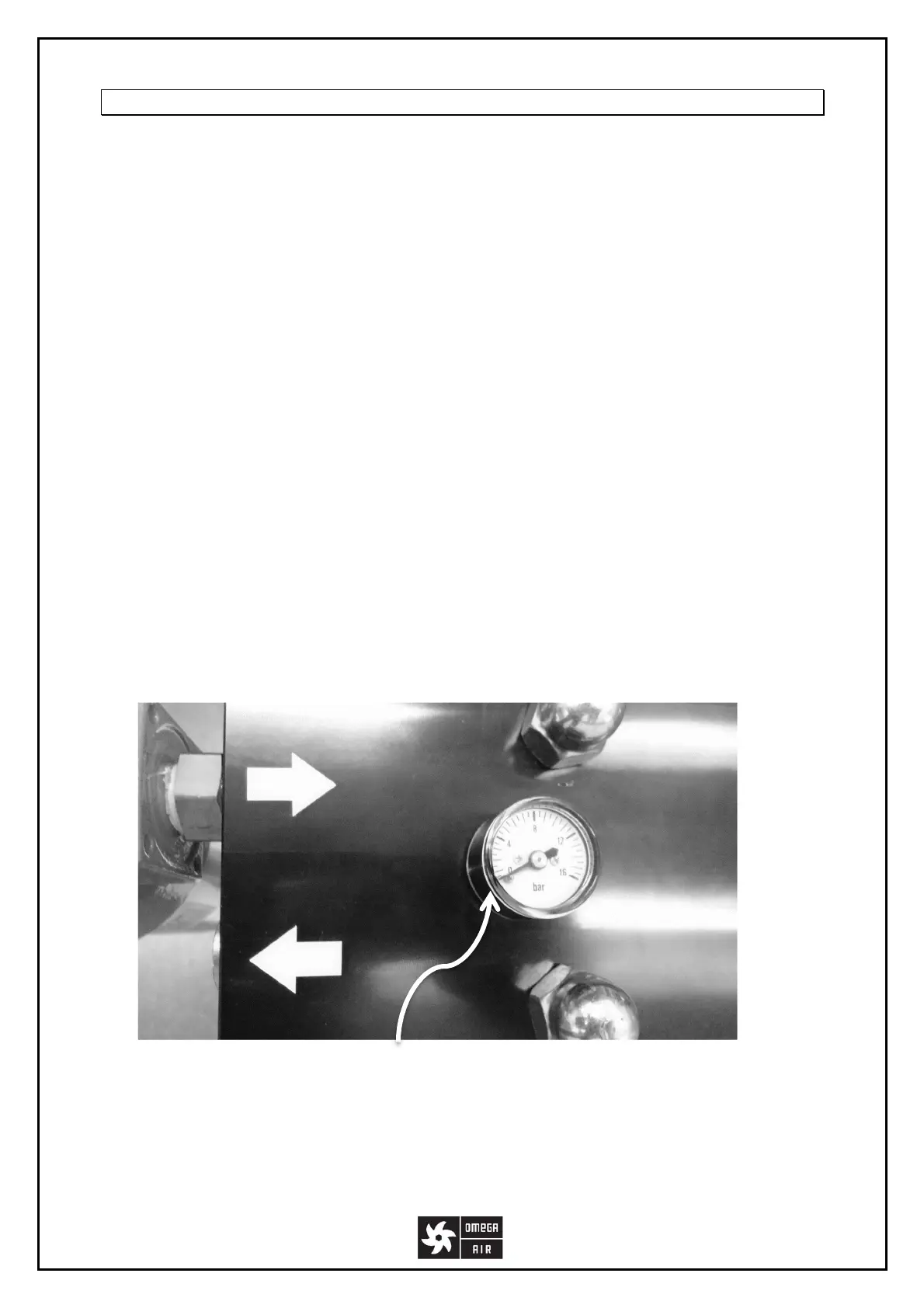

5. Malfunctioning manometer: In this case the dryer is operating correctly but a faulty

manometer indicates that the tower has not depressurized. If the manometer is

faulty it will show that the tower is pressurized even when the dryer is offline and

unpressurised. Contact your supplier and replace the manometer.

Manometer indication on unpressurised dryer

Loading...

Loading...