A Appendices

A - 22

E5@C Digital Temperature Controllers User’s Manual (H174)

If the Digital Controller is not operating normally, check the following points before requesting repairs. If

the problem persists, contact your OMRON representative for details on returning the product.

*1 Also refer to the E5

@

C Digital Controllers Communications Manual (Cat. No. H175) for details.

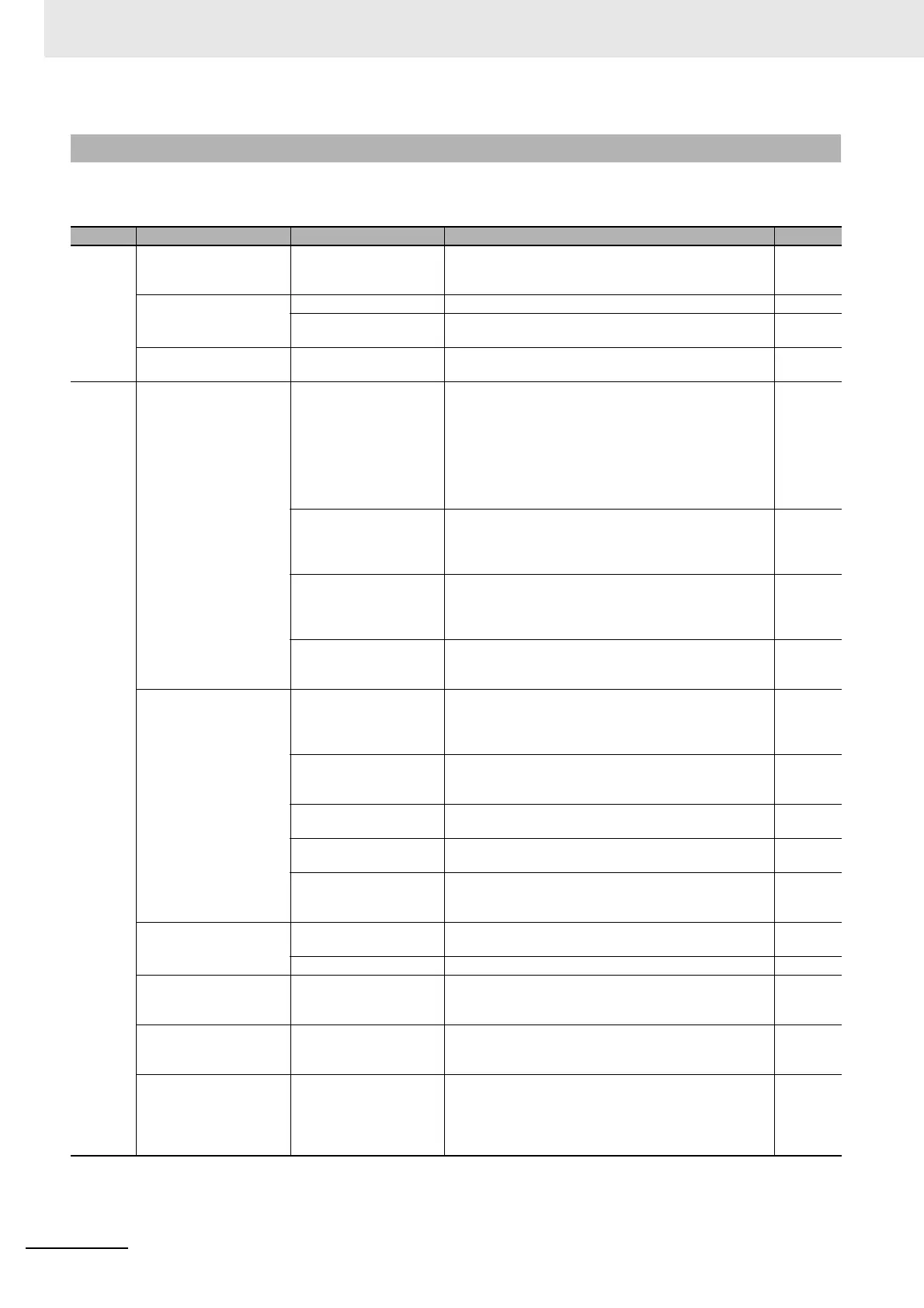

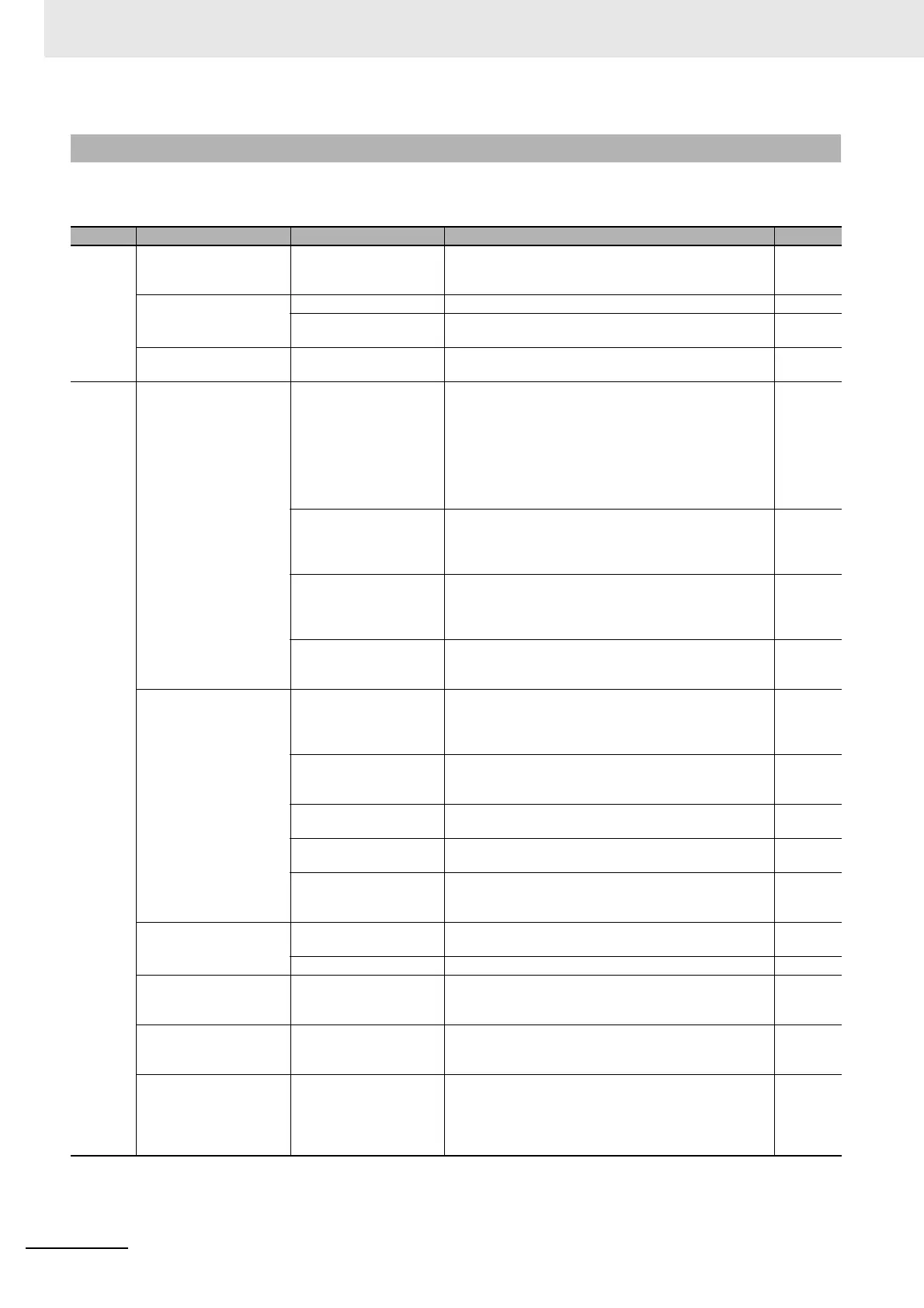

A-5-2 Checking Problems

Timing Status Meaning Countermeasures Page

Turning

ON the

power for

the first

time

The TUNE indicator will

flash.

ST (self-tuning) is in

progress (default setting:

ON).

This is not a product fault.

The TUNE indicator flashes during self-tuning.

4-27

Temperature error is

large.

Input error (S.Err display)

Input type mismatch Check the sensor type and reset the input type correctly. 4-12

Thermometer is not

installed properly.

Check the thermometer installation location and polarity

and install correctly.

2-25,

2-41

Communications are not

possible.

Non-recommended

adapter is being used.

Make sure that the connected device is not faulty.

*

1

During

operation

Overshooting

Undershooting

Hunting

ON/OFF control is

enabled (default: ON/OFF

control selected).

Select PID control and execute either ST (self-tuning) or

AT (auto-tuning).

When using self-tuning, turn ON the power supply to the

Digital Controller and load (heater, etc.) at the same time,

or turn ON the load power supply first. Accurate

self-tuning and optimum control will not be possible if the

power supply to the load is turned ON after turning ON the

power supply to the Digital Controller.

4-24

Control period is longer

compared with the speed

of rise and fall in

temperature.

Shorten the control period. A shorter control period

improves control performance, but a cycle of 20 ms

minimum is recommended in consideration of the service

life of the relays.

4-15

Unsuitable PID constant Set appropriate PID constants using either of the following

methods.

• Execute AT (autotuning).

• Set PID constants individually using manual settings.

4-24

HS alarm operation fault Use breeder resistance if the problem is due to leakage

current. Also investigate the errors detected by the HS

alarm function.

4-42

Temperature is not rising Specified operation is

unsuitable for required

control (default: Reverse

operation).

Select either forward or reverse operation depending on

the required control. Reverse operation is used for heating

operations.

4-15

Heater is burnt out or

deteriorated.

Check whether heater burnout or deterioration have

occurred. Also investigate the errors detected by the

heater burnout alarm.

4-40

Insufficient heater

capacity

Check whether the heater's heating capacity is sufficient. ---

Cooling system in

operation.

Check whether a cooling system is operating. ---

Peripheral devices have

heat prevention device

operating.

Set the heating prevention temperature setting to a value

higher than the set temperature of the Digital Controller.

---

The AT Execute/Cancel

parameter (at) is not

displayed.

ON/OFF control is

enabled.

Set the PID ON/OFF parameter to PID. 6-45

The Controller is stopped. Set the RUN/STOP parameter to RUN. 6-13

The SP Ramp Set Value

parameter (sprt) is not

displayed.

ST is enabled Set the ST parameter to OFF. 6-33

The Remote SP Enable

parameter (rspu) is not

displayed.

ST is enabled Set the ST parameter to OFF. 6-85

The Alarm 1 Type

parameter (alt1) is not

displayed.

The Auxiliary Output 1

Assignment parameter is

set to a heater alarm for a

Controller with heater

burnout detection.

Set the Auxiliary Output 1 Assignment parameter to Alarm

1. The default setting is for a heater alarm (HA).

6-83

Loading...

Loading...