G-10 Automatic Mounting of PCB Relays

A Through-hole PCBs

When mounting a Relay to a PCB, take the following points into consideration for each

process. There are also certain mounting precautions for individual Relays, so refer to the

individual Relay precautions as well.

Process 1

Placement

1. Do not bend any terminals of the Relay to use it as a self-clinching Relay.

The initial performance characteristics of the Relay will be lost.

2. Execute PCB processing correctly according to the PCB process diagrams.

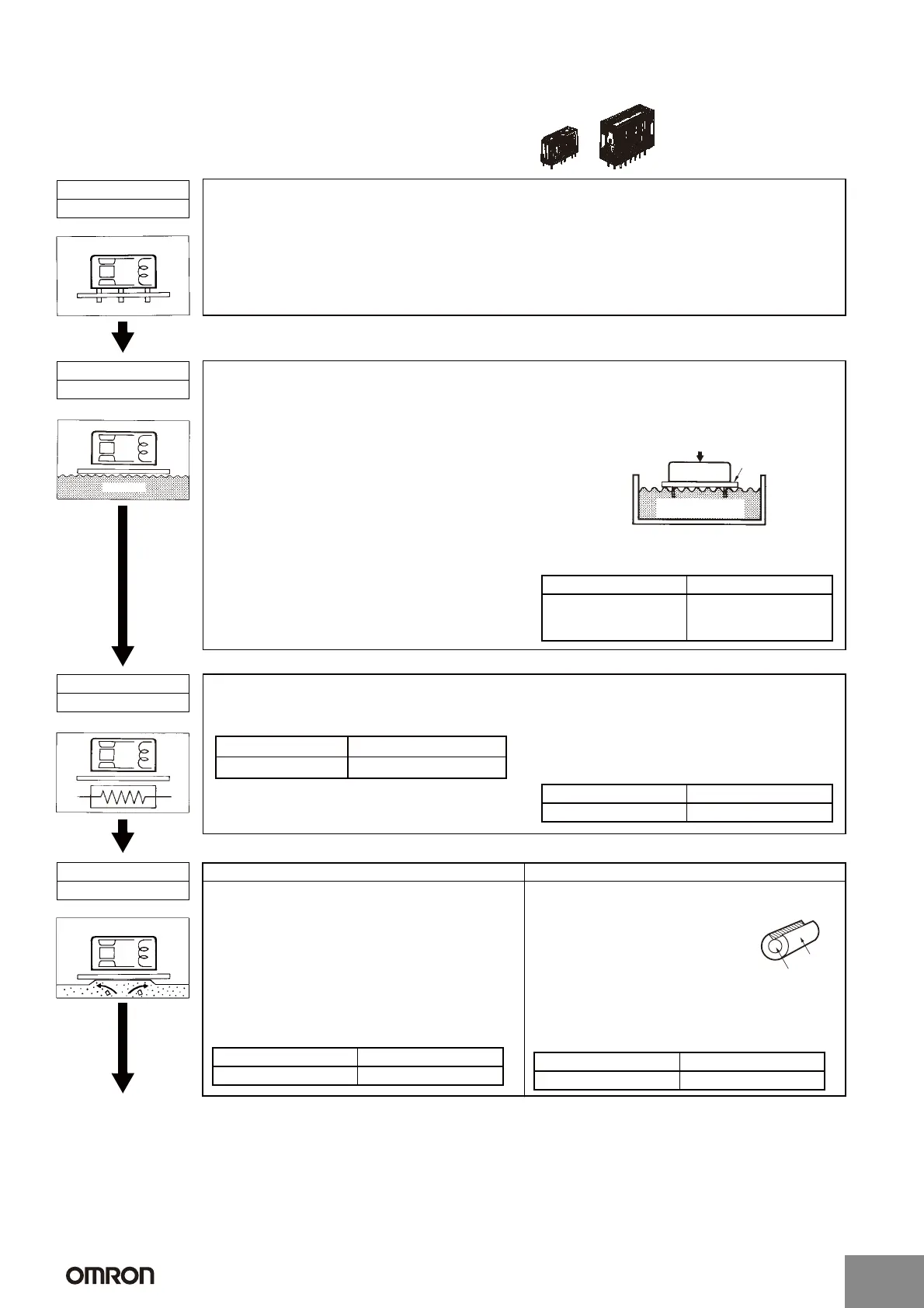

Process 2

Flux Application

Flux

1. The G7S has no protection against flux

penetration, so absolutely do not use the method

shown in the diagram on the right, in which a

sponge is soaked with flux and the PCB pressed

down on the sponge. If this method is used for the

G7S, it will cause the flux to penetrate into the

Relay. Be careful even with the flux-resistant

G7SA, because flux can penetrate into the Relay

if it is pressed too deeply into the sponge.

2. The flux must be a non-corrosive rosin-based flux

suitable for the Relay's structural materials.

For the flux solvent, use an alcohol-based solvent,

which tends to be less chemically reactive.

Apply the flux sparingly and evenly to prevent

penetration into the Relay.

When dipping the Relay terminals into liquid flux,

be sure to adjust the flux level, so that the upper

surface of the PCB is not flooded with flux.

3. Make sure that flux does not adhere anywhere

outside of the Relay terminals. If flux adheres to

an area such as the bottom surface of the Relay, it

will cause the insulation to deteriorate.

Applicability of Dipping Method

G7S G7SA

NO YES

(Must be checked when

spray flexor is used.)

Pressing deeply

Relay

Sponge soaked with

flux

PCB

Example of incorrect method

Process 3

Preheating

Heater

1. Preheating is required to create the optimum

conditions for soldering.

2. The following conditions apply for preheating.

3. Do not use a Relay if it has been left at a high

temperature for a long period of time due to a

circumstance such as equipment failure. These

conditions will cause the Relay's initial

characteristics to change.

Applicability of Preheating

Temperature 100°C max.

Time 1 min max.

G7S G7SA

NO YES

Note: For lead-free solder, perform the soldering under conditions that conform to the applicable specifications.

Automatic soldering Manual soldering

1. Flow soldering is recommended to assure a uniform

solder joint.

• Solder: JIS Z3282 or H63A

• Solder temperature and soldering time: Approx. 250°C

(DWS: Approx. 260°C)

• Solder time: 5 s max. (DWS: Approx. 2 s for first time

and approx. 3 s for second time)

• Adjust the level of the molten solder so that the PCB is

not flooded with solder.

Applicability of Automatic Soldering

1. Smooth the solder with the tip of the iron, and then

perform the soldering under the following conditions.

• Solder: JIS Z3282, H60A, or H63A

(containing rosin-based flux)

• Soldering iron: Rated at 30 to 60 W

• Tip temperature: 280 to 300°C

• Soldering time: Approx. 3 s max.

2. As shown in the above illustration, solder is available

with a cut section to prevent flux from splattering.

Applicability of Manual Soldering

G7S G7SA

NO YES

Solder

Flux

G7S G7SA

YES YES

Process 4

Soldering

Continued next

page.

http://www.ia.omron.com/

C-13

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...