12 - 45

12 Troubleshooting

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

12-5 Troubleshooting

12

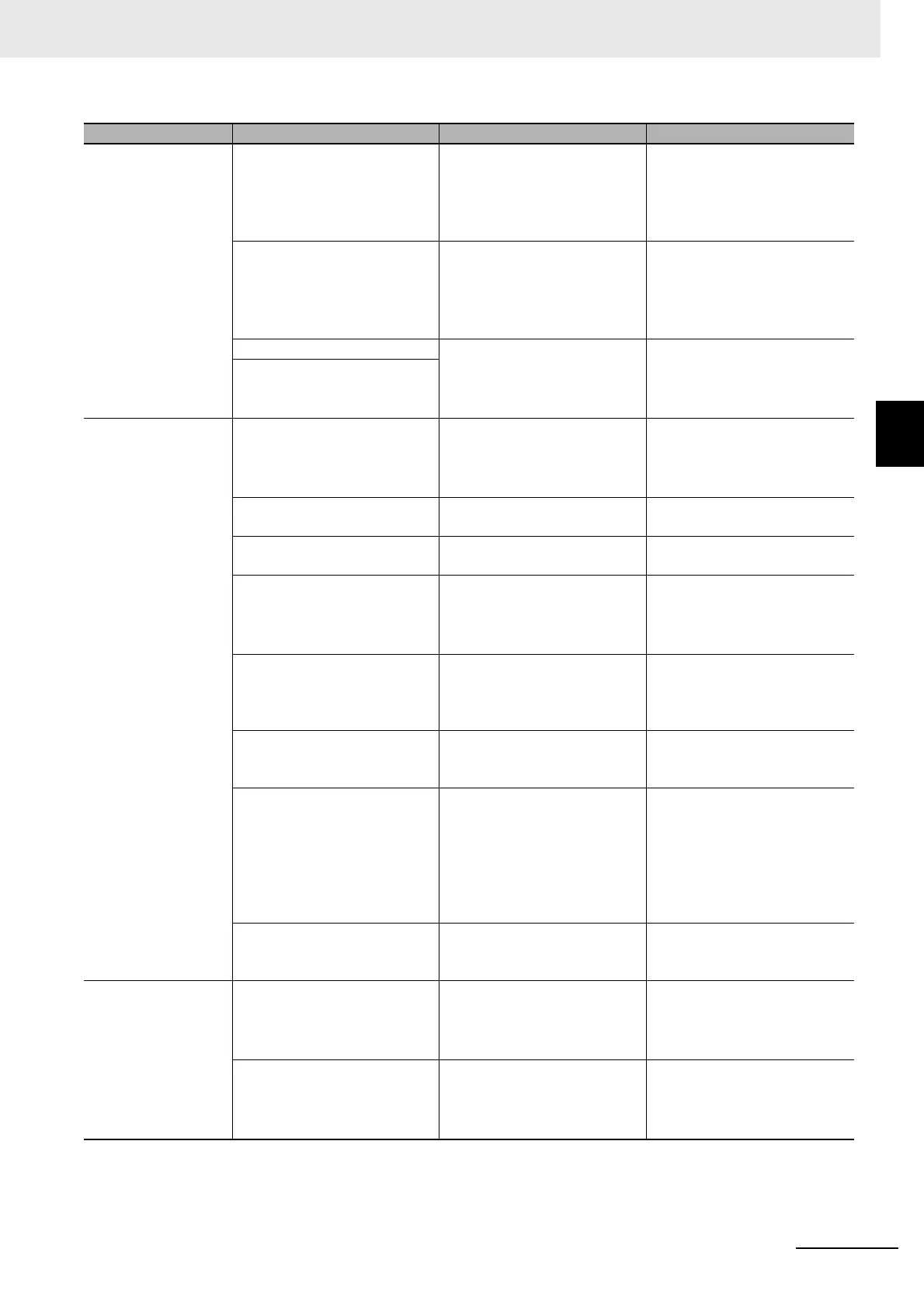

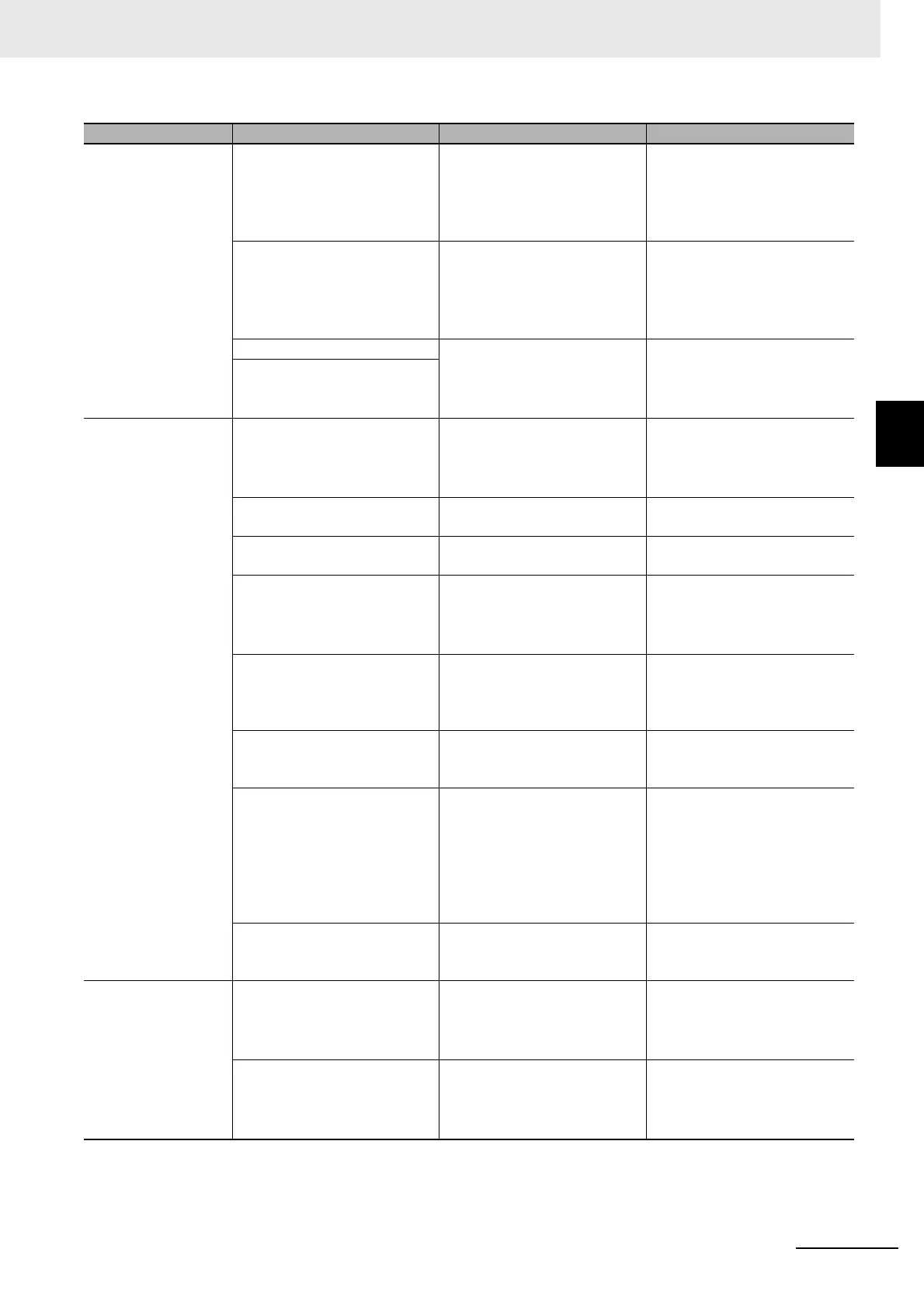

12-5-3 Troubleshooting Using the Operation State

The Servomotor is

overheating.

The ambient temperature is too

high.

Check to see if the ambient

temperature around the Servo-

motor is over 40°C.

• Lower the ambient tempera-

ture around the Servomotor

to 40°C or less. (Use a fan or

air conditioner.)

• Lower the load ratio.

The heat radiation condition for

the Servomotor is inappropri-

ate.

• Check to see if the specified

radiation conditions are

observed.

• For a Servomotor with a

brake, check the load ratio.

• Improve the radiation condi-

tions.

• Reduce the load.

• Improve ventilation.

The Servomotor is overloaded. Check the torque with the Sys-

mac Studio.

• Decrease the acceleration

and deceleration rates.

• Lower the speed and check

the load.

The Servomotor vibrates during

rotation.

The machine position

is misaligned.

The coupling of the motor shaft

and the machine is abnormal.

Check to see if the coupling of

the Servomotor and the

machine is misaligned.

• Tighten the coupling again.

• Replace the coupling with a

coupling that has no loose-

ness.

The host controller gave a

deceleration stop command.

Check the control ladder pro-

gram in the host controller.

Review the control in the host

controller.

The gain is wrong. --- Check if manual tuning can

achieve proper adjustment.

The load inertia is too large. • Check the load inertia.

• Check the Servomotor rota-

tion speed.

• Review the load inertia.

• Replace the Servomotor and

Servo Drive with proper

ones.

The power supply was turned

ON while the encoder

multi-rotation exceeded the

limit value.

Check Encoder - Multi-

rotation Data.

Perform the operation within

the multi-rotation range.

The command value from the

host controller is not correct.

Check the control ladder pro-

gram and settings in the host

controller.

Review the control and settings

in the host controller.

The home position was shifted. • Check the home position of

the absolute encoder.

• Check whether homing is

performed normally.

• Adjust the mechanical home

and home position of the

absolute encoder.

• Change the setting or input

signals so that the correct

home position can be defined

during homing.

The set values of the Servo

Drive do not match the

machine.

Check the settings of gear

ratio, gain, maximum torque,

etc.

Adjust the set values so that

they match the machine.

The Servomotor does

not stop or is hard to

stop even if the Servo

is turned OFF while

the Servomotor is

rotating.

The load inertia is too large. • Check the load inertia.

• Check the Servomotor rota-

tion speed.

• Review the load inertia.

• Replace the Servomotor and

Servo Drive with proper

ones.

The dynamic brake is disabled. Check if the dynamic brake is

disabled or broken.

• Enable the dynamic brake, if

it is disabled.

• Replace the dynamic brake if

it is broken.

Symptom Probable cause Check items Measures

Loading...

Loading...