4 Configuration and Wiring

4 - 12

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

Installing Decelerator into the Machine

When you install the R88G-HPG into the machine, confirm that the mounting surface is flat

and there are no burrs on the tap sections, and fix the mounting flange with bolts.

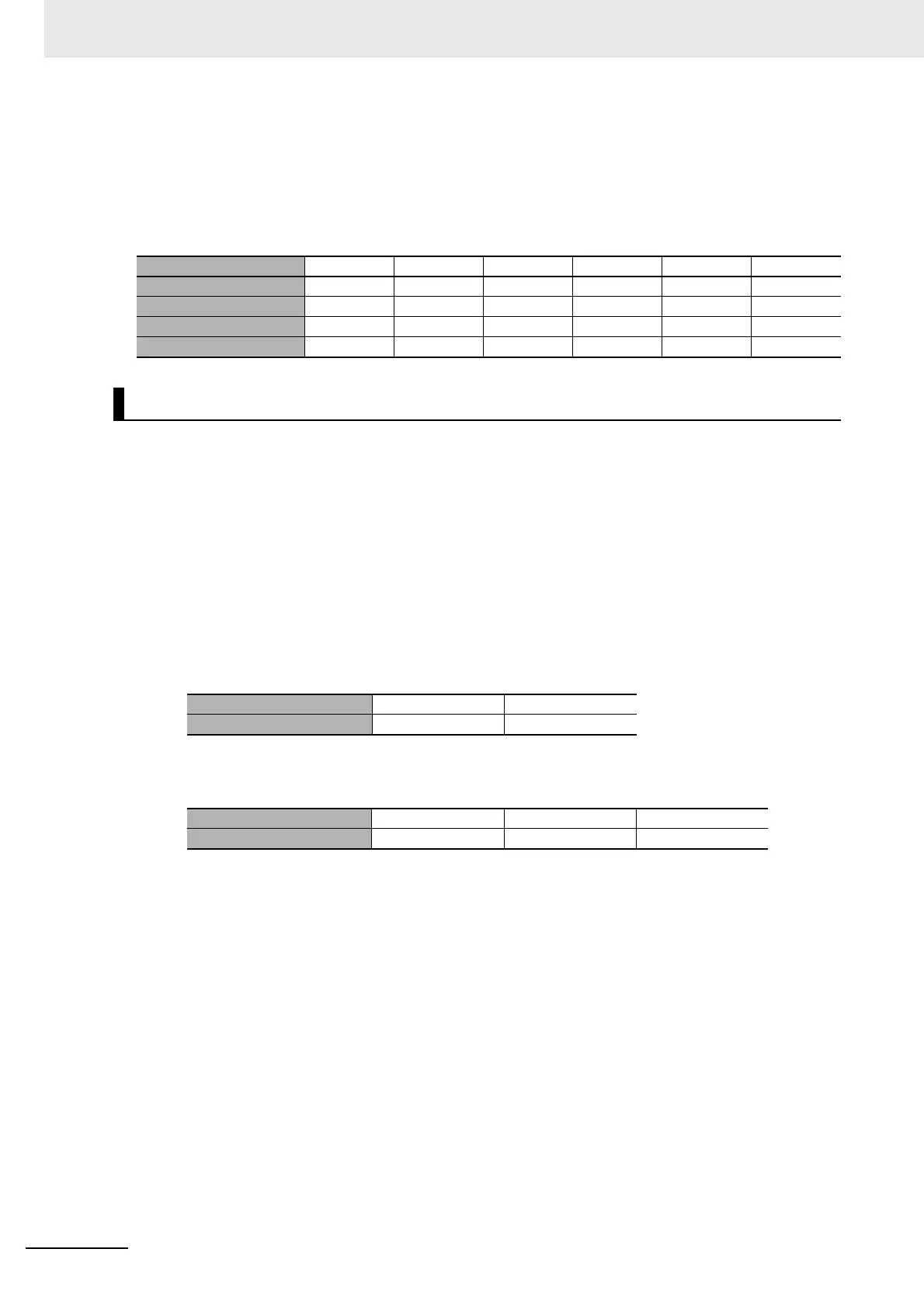

Bolt tightening torque on the mounting flange (for aluminum)

Follow the instructions bellow for installing this Decelerator and the Servomotor.

1 Turn the input joint and align the head of the bolt that secures the shaft with the rubber cap.

Check that the set bolt is loose.

2 Gently insert the Servomotor into the Decelerator.

Put up the decelerator vertically and slide the Servomotor into the input shaft joint while using

the motor shaft as guide not to fall over, as shown in the figures on the next page. When the

Decelerator cannot be put up vertically, tighten each bolt evenly little by little to ensure that the

Servomotor is not inserted at a tilt.

3 Fix the Servomotor and the flange of the Decelerator with bolts.

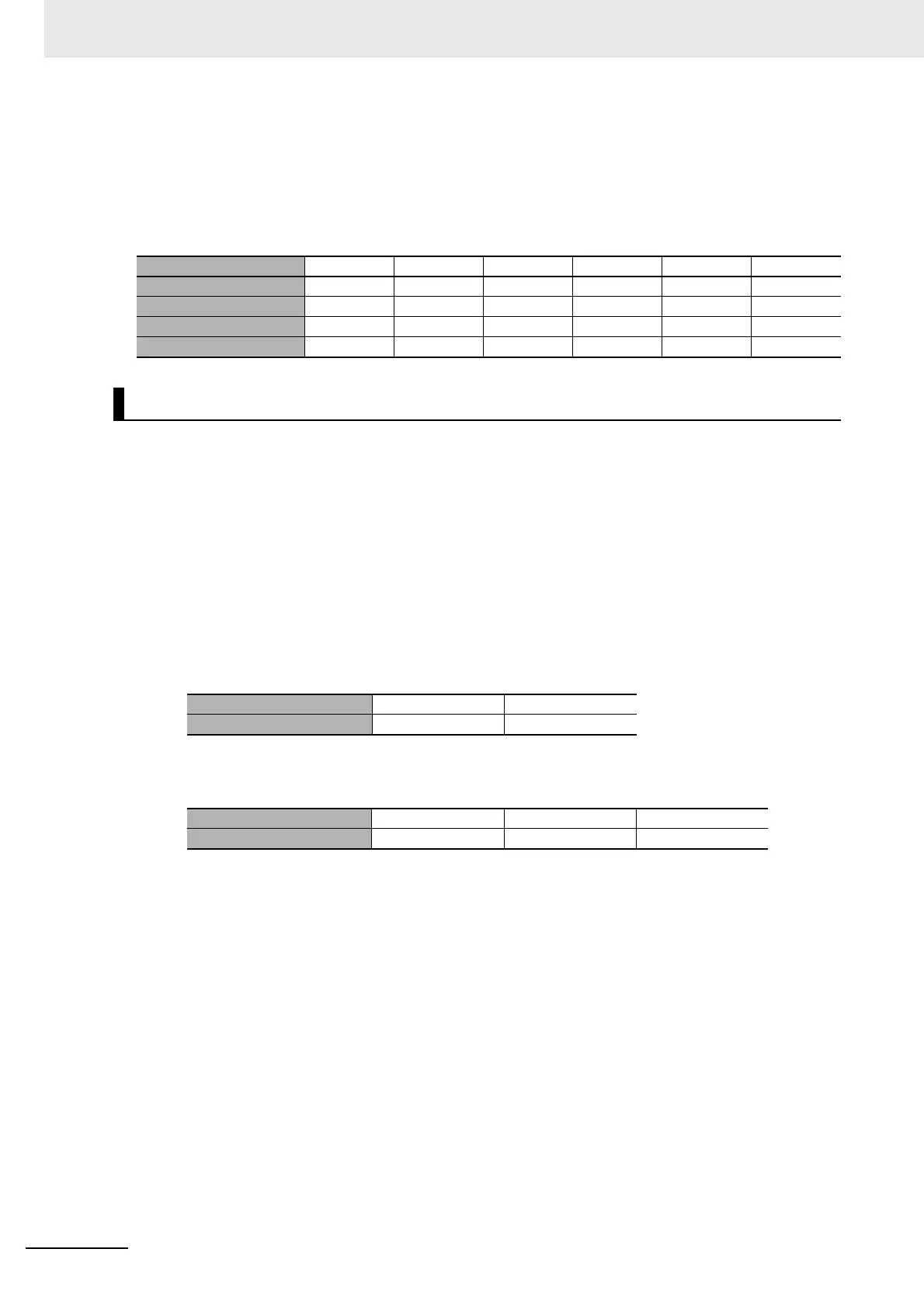

Bolt tightening torque

4 Tighten the bolts of the input joint.

Bolt tightening torque (for duralumin)

Note Tighten the bolts to the torque indicated on the above table. A problem such as slipping may occur if the

specified torque level is not satisfied.

R88G-HPG 11B 14A 20A 32A 50A 65A

Number of bolts 444444

Size of bolts M3 M5 M8 M10 M12 M16

Mounting PCD [mm] 46 70 105 135 190 260

Tightening torque [N·m] 1.4 6.3 26.1 51.5 103 255

Installing the R88G-VRXF (15 Arcminutes Type)

Allen head bolt size M4 M5

Tightening torque [N·m] 2.5 5.1

Allen head bolt size M4 M5 M6

Tightening torque [N·m] 4.3 8.7 15

Loading...

Loading...