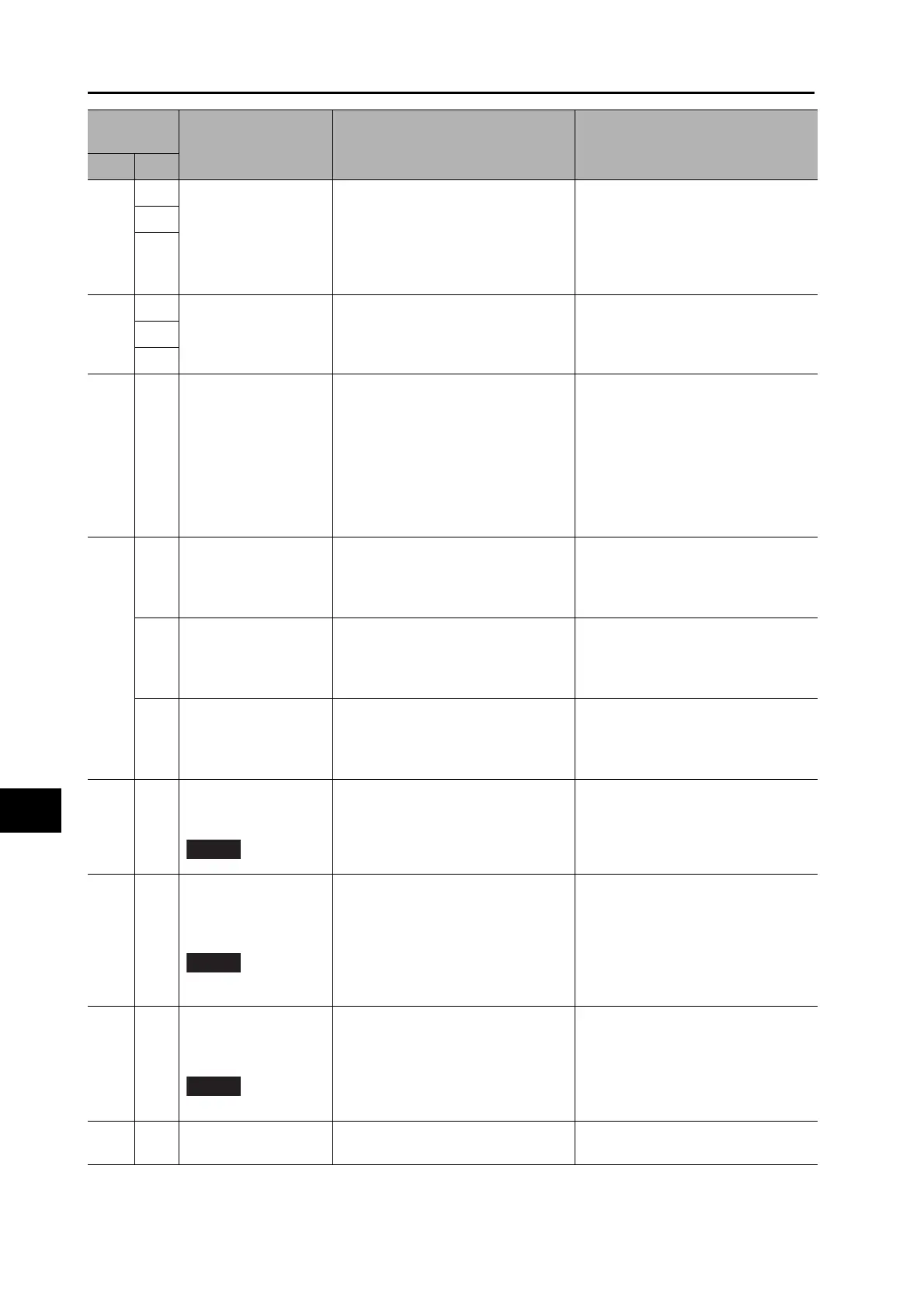

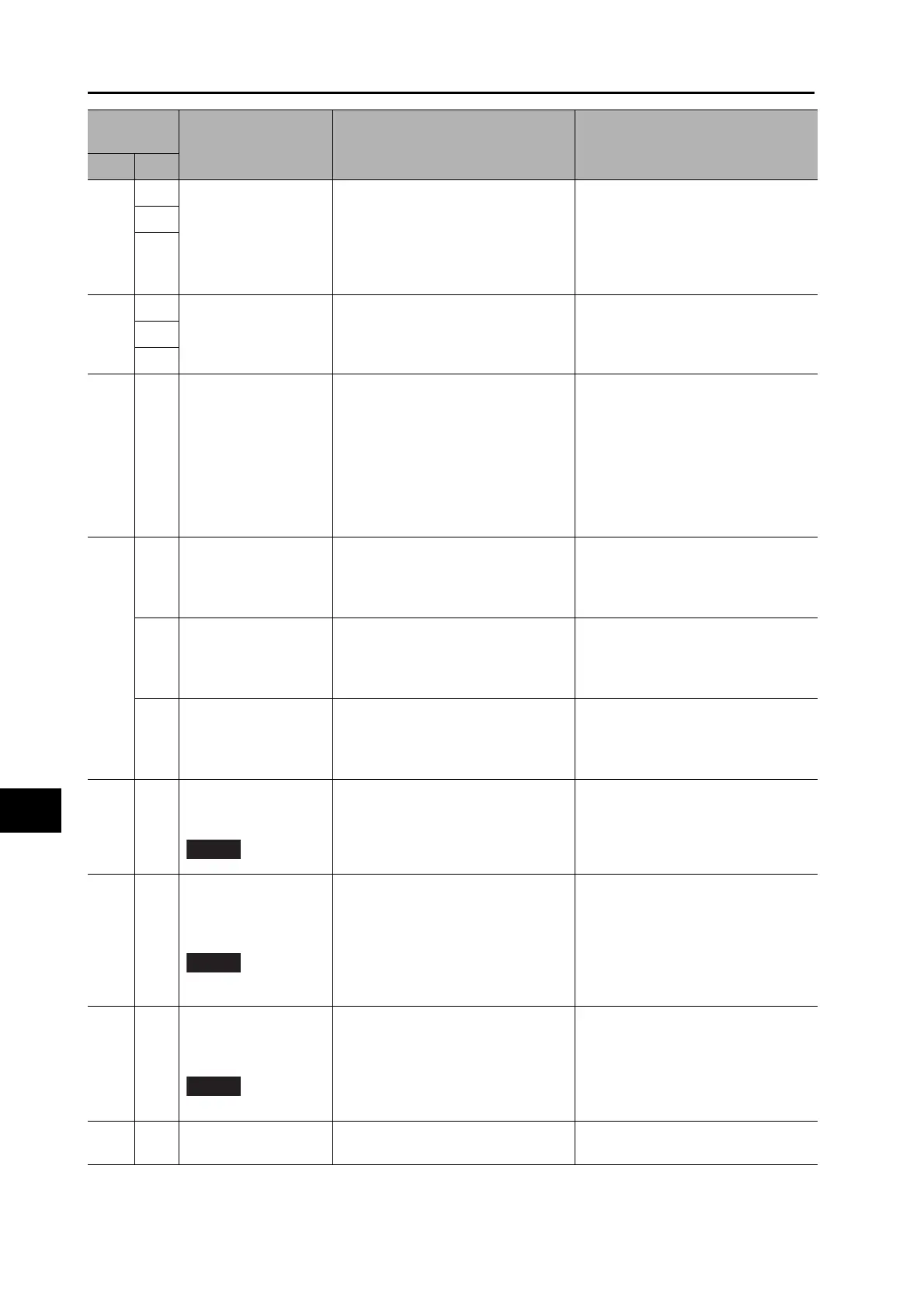

11-19

11-4 Troubleshooting

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

11

Troubleshooting and Maintenance

36

0

Parameter error

Data in the Parameter Save area was

corrupted when the power supply was

turned ON and data was read from

the EEPROM.

· Reset all parameters.

· If this error occurs repeatedly, the

Servo Drive may be faulty. In this

case, replace the Servo Drive.

Return the Servo Drive to the

dealer that it was purchased from.

1

2

37

0

Parameters

destruction

EEPROM write verification data was

corrupted when the power supply was

turned ON and data was read from

the EEPROM.

The Servo Drive is faulty. Replace the

Servo Drive. Return the Servo Drive

to the dealer that it was purchased

from.

1

2

38 0

Drive prohibition input

error

When the Drive Prohibition Input

Selection (Pn504) was set to 0, both

the Forward Drive Prohibition Input

(POT) and the Reverse Drive

Prohibition Input (NOT) turned ON.

When Pn504 was set to 2, either the

Forward Drive Prohibition input or the

Reverse Drive Prohibition input

turned ON.

Check for any problems with the

switches, wires, and power supplies

that are connected to the forward

drive prohibition input or the reverse

drive prohibition input. In particular,

check to see if the external DC power

supply (12 to 24 VDC) for sequence

inputs turned ON too slowly.

39

0

Excessive analog input

1

A voltage that exceeded the value set

for the Excessive Analog Input 1

(Pn424) was applied to analog input

1.

· Set the Pn424 correctly. Check

the connections to CN1.

· Set Pn424 to 0 to disable alarm

detection.

1

Excessive analog input

2

A voltage that exceeded the value set

for the Excessive Analog Input 2

(Pn427) was applied to analog input

2.

· Set the Pn427 correctly. Check

the connections to CN1.

· Set Pn427 to 0 to disable alarm

detection.

2

Excessive analog input

3

A voltage that exceeded the value set

for the Excessive Analog Input 3

(Pn430) was applied to analog input

3.

· Set the Pn430 correctly. Check

the connections to CN1.

· Set Pn430 to 0 to disable alarm

detection.

40 0

Absolute encoder

system down error

The voltage of the built-in capacitor

dropped below the specified value

because the power supply to the

encoder or the battery power supply

was down.

Connect the battery power supply,

and then clear the absolute encoder.

Unless the absolute encoder is

cleared, the error cannot be reset.

41 0

Absolute encoder

counter overflow error

The multi-rotation counter of the

encoder exceeded the specified

value.

· Set the Operation Switch when

Using Absolute Encoder (Pn015)

to an appropriate value.

· Make sure that the traveling

distance from the origin of the

machine is no more than 32,767

revolutions.

42 0

Absolute encoder

overspeed error

The Servomotor rotation speed

exceeded the specified value when

on

ly the b

attery power supply was

used during a power interruption.

· Check the power supply voltage (5

VDC ± 5%) at the encoder.

· Check the connections to

connector CN2. Unless the

absolute encoder is cleared, the

error cannot be reset.

43 0

Encoder initialization

error

An encoder initialization error was

detected.

Replace the Servomotor.

Alarm

number

Name Cause Measures

Main Sub

Loading...

Loading...